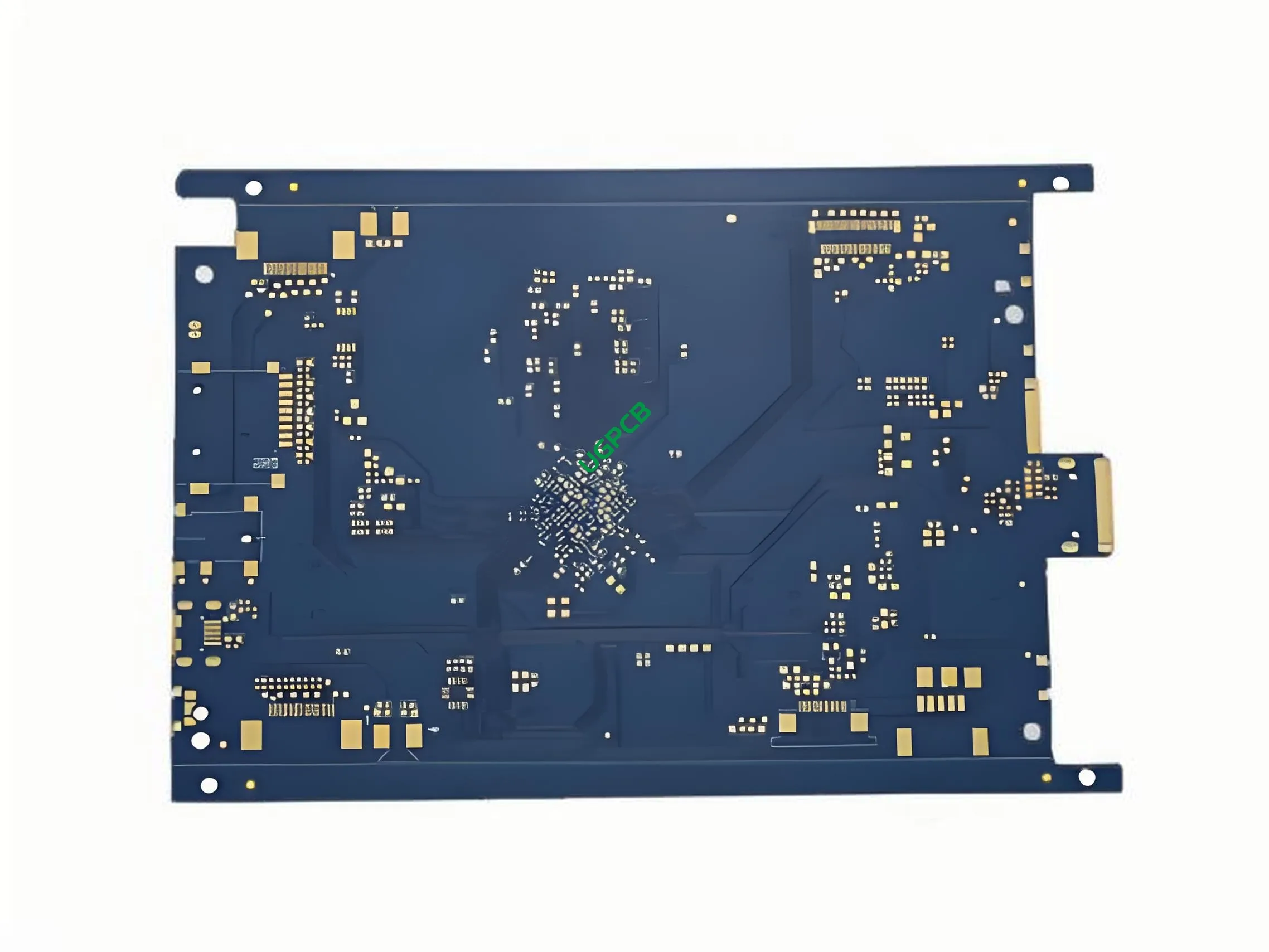

소개 6 레이어 PCB

그만큼 6 Layer PCB is a sophisticated 전자 구성 요소 designed for high-performance applications requiring complex circuitry. It consists of six layers of conductive material, 일반적으로 구리, 절연 층으로 분리됩니다. This multilayer structure allows for greater functionality and compactness compared to single or double-sided PCBs.

무엇입니까? 6 레이어 PCB?

에이 6 레이어 PCB, 또는 인쇄 회로 기판, is an advanced electronic substrate that features six layers of conductive pathways embedded within insulating layers. These layers are meticulously arranged to create intricate circuit designs suitable for demanding electronic applications. The additional layers provide enhanced signal integrity, 전력 분배, and thermal management capabilities.

설계 요구 사항

Designing a 6 Layer PCB involves several critical considerations:

- 재료 선택: Common materials include S1141, S1000, 그리고 370HR, chosen based on their electrical properties and compatibility with the manufacturing process.

- 레이어 스택 업: Determines the arrangement of signal and ground planes, crucial for minimizing crosstalk and ensuring reliable signal transmission.

- 구리 두께: Typically specified as 1/H/H/H/H1 OZ, indicating varying thicknesses across different layers to optimize performance and cost.

- 표면 처리: Options like Immersion Gold or OSP (Organo-Silicon Protection) are applied to protect the copper surfaces and enhance solderability.

어떻게 작동하나요??

그만큼 6 Layer PCB functions by providing a platform for electrical components to be interconnected through a series of conductive paths etched onto its surface. Each layer contains specific patterns of copper traces that form circuits when connected via plated through-holes or vias. The multiple layers enable more complex circuit designs without increasing the board’s footprint, making it ideal for modern electronic devices where space is limited.

응용

Due to their complexity and capability to handle high-speed signals with minimal interference, 6 Layer PCBs are widely used in consumer electronics such as smartphones, 정제, 노트북, 및 기타 휴대용 장치. They are also found in automotive electronics, 의료 장비, and industrial controls where reliability and performance are paramount.

분류

6 Layer PCBs can be classified based on several factors:

- 재료로: As mentioned, they may use S1141, S1000, or 370HR depending on the required characteristics.

- 응용 프로그램에 의해: General-purpose or specialized for specific industries like telecommunications, 항공우주, or defense.

- 표면 처리에 의한: Different finishes like Immersion Gold or OSP cater to various environmental conditions and soldering processes.

사용된 재료

The primary materials used in manufacturing 6 Layer PCBs include:

- 기본 재료: Often fiberglass-reinforced epoxy resins (FR-4), which offer excellent mechanical strength and thermal stability.

- 구리 포일: Varying thicknesses are used to balance conductivity and cost-effectiveness.

- 솔더 마스크: Typically green in color, 산화 및 우발적인 단락으로부터 구리 트레이스를 보호합니다..

- 실크스크린: A white coating used for labeling components and providing instructions for assembly.

성능 특성

Key performance attributes of a 6 Layer PCB include:

- 신호 무결성: Enhanced by strategic layer placement and grounding schemes.

- 열 관리: Improved heat dissipation due to larger copper areas and potentially thicker boards.

- 기계적 강도: Multilayer construction adds rigidity, reducing the risk of damage during handling or operation.

구조적 구성

구조적으로, 에이 6 Layer PCB comprises:

- 전도성 층: Six layers of copper traces separated by dielectric materials.

- 절연층: 전도성 층 사이의 전기적 단락 방지.

- vias: Conductive holes that connect different layers, allowing vertical integration of circuits.

독특한 특징

Some notable features of a 6 Layer PCB are:

- 고밀도: Allows for complex circuit designs within a compact form factor.

- 신뢰할 수 있음: Multilayer design improves resistance to electromagnetic interference (EMI).

- 다재: Suitable for a wide range of applications due to customizable layer configurations and material choices.

생산 과정

The manufacturing process of a 6 Layer PCB involves several steps:

- 디자인 및 레이아웃: 전문 소프트웨어를 사용하여 회로 패턴 생성.

- 재료 준비: 기본 재료를 크기에 맞게 절단하고 표면을 청소합니다..

- 라미네이션: 열과 압력을 가해 개별 레이어를 적층하고 접착.

- 에칭: 원하는 회로 경로를 형성하기 위해 과도한 구리를 제거합니다..

- 도금: 비아와 노출된 구리 영역에 얇은 금속층 추가.

- 솔더 마스크 적용: Applying the green coating to protect traces.

- 실크스크린 인쇄: Adding text and symbols for component placement.

- 최종검사: 배송 전 품질과 기능성 보장.

사용 사례

Common scenarios where a 6 Layer PCB might be employed include:

- High-density interconnect applications in mobile devices.

- 낮은 신호 손실이 요구되는 고급 통신 시스템.

- 열악한 환경에서 안정적인 성능이 필요한 휴대용 의료 기기.

- 견고성과 수명을 요구하는 자동차 전자 장치.

요약하면, 그만큼 6 Layer PCB represents a significant advancement in printed circuit board technology, offering unparalleled complexity and performance for modern electronic applications. Its design flexibility, combined with superior signal integrity and durability, makes it an essential component in the development of next-generation consumer electronics and beyond.

UGPCB 로고

UGPCB 로고