Revolutionizing PCB Excellence: UGPCB’s Advanced AOI Horizontal Paper Insertion Board Unloader

In the rapidly evolving world of electronics manufacturing, UGPCB has consistently demonstrated its commitment to technological excellence and innovation. The recent addition of the state-of-the-art AOI horizontal paper insertion board unloader to our production facility represents a significant leap forward in our quest for manufacturing perfection. This advanced equipment complements our comprehensive PCB and PCBA manufacturing services, reinforcing our position as an industry leader dedicated to delivering unmatched quality, precizie, and reliability to our clients worldwide.

The Critical Role of AOI in Modern PCB Manufacturing

Inspecție optică automată (Aoi) has become an indispensable quality control component in electronics manufacturing. Ca Proiecte PCB grow more complex with finer traces, higher component densities, and increasingly stringent reliability requirements, the implementation of robust inspection systems becomes crucial. According to industry research, AOI systems can detect up to 98% of manufacturing defects before boards proceed to subsequent production stages, significantly reducing rework costs and improving final product quality.

The integration of AOI technology is particularly vital for manufacturers serving high-reliability industries such as aerospace, dispozitive medicale, și electronice auto, where failure is not an option . UGPCB’s strategic investment in the AOI horizontal paper insertion board unloader demonstrates our understanding of these critical quality imperatives and our commitment to providing customers with the highest levels of manufacturing excellence.

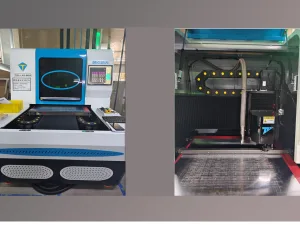

Technical Specifications of UGPCB’s AOI Horizontal Paper Insertion Board Unloader

UGPCB’s newly acquired AOI horizontal paper insertion board unloader features cutting-edge engineering designed to optimize the Fabricarea PCB-urilor workflow:

-

Board Handling Capacity: Capable of processing boards up to 400kg in weight with thickness up to 350mm

-

Board Size Compatibility: Versatile handling of both 750mm and 650mm circuit boards

-

Processing Speed: Remarkable 3-second board exchange time with horizontal movement for minimal throughput disruption

-

Paper Insertion Mechanism: Advanced automatic paper insertion system that distinguishes between separator papers and boards

-

Intelligent Operation: User-friendly HMI interface with 1-to-1 and 1-to-2 operational mode switching flexibility

-

Integration Capabilities: Seamless connectivity with AOI automation equipment and AGV transportation systems

-

Quick Changeover: 30-second recipe switching capability supporting high-mix, low-volume production environments

-

Maintenance Features: Modular design allowing lateral displacement for maintenance without affecting production

Enhancing PCB Quality Through Advanced Automation

The implementation of this sophisticated board unloader system has transformed quality control processes at UGPCB. The equipment’s precision paper insertion mechanism prevents surface scratches and abrasions during board handling and transportation, preserving the integrity of delicate circuit traces and components. This is particularly crucial for boards with fine-pitch components şi high-density interconnects where even minor surface damage can impact performance and reliability.

The integrated anti-static dust removal system featuring imported adhesive roller technology effectively captures microscopic contaminants that could potentially cause latent failures in the field . This attention to detail in board handling aligns with UGPCB’s commitment to producing electronic assemblies of the highest reliability, suitable for even the most demanding applications.

UGPCB’s technical capabilities extend beyond standard commercial requirements, with demonstrated expertise in producing PCBs that exceed Clasa IPC-A-610 3 Standarde for specialized electronic products used in medical, aerospațial, and extreme environment applications .

Streamlining PCBA Production Workflows

In the competitive landscape of Fabricarea PCBA, production efficiency directly correlates with cost-effectiveness and time-to-market. UGPCB’s AOI horizontal paper insertion board unloader introduces significant operational efficiencies to our SMT lines and final assembly processes. The equipment’s rapid 3-second board transfer capability represents a substantial improvement over traditional manual handling methods, reducing non-value-added time in the production cycle.

The machine’s intelligent sorting capability automatically separates conforming and non-conforming boards based on AOI inspection results , ensuring that only boards meeting UGPCB’s stringent quality standards progress to subsequent manufacturing stages. This automated decision-making eliminates human error in board classification while providing valuable real-time production data that enhances overall process control and traceability.

The modular design philosophy of the equipment enables rapid maintenance and changeover, with the ability to displace the unit from the production line for service in less than 5 minute . This design consideration maximizes equipment uptime and supports UGPCB’s commitment to maintaining aggressive production schedules without compromising quality.

UGPCB’s Comprehensive PCB and PCBA Manufacturing Capabilities

The AOI horizontal paper insertion board unloader represents just one element of UGPCB’s comprehensive manufacturing ecosystem. Our technical capabilities span the entire product development lifecycle, positioning UGPCB as a trusted manufacturing partner for clients across diverse industry sectors.

Advanced PCB Fabrication Expertise

UGPCB specializes in producing sophisticated printed circuit boards that meet the challenges of modern electronic design:

-

Interconectare de înaltă densitate (HDI) PCB -uri: Supporting designs with complex blind and buried vias for space-constrained applications

-

Multi-Layer Boards: Capability to manufacture boards with up to 100 layers for complex electronic systems

-

Specialized Substrates: Experience with materiale de înaltă frecvență, rigid-flex combinations, and embedded component boards

-

Precision Manufacturing: Support for trace widths/spacing down to 1.5mil and controlled impedance with ±5% tolerance

-

Varied PCB Technologies: Expertise in producing heavy copper, mixed dielectric, and via-in-pad designs

State-of-the-Art PCBA Services

UGPCB’s assembly capabilities leverage cutting-edge equipment and proven processes to deliver exceptional results:

-

Tehnologia de montare a suprafeței: High-precision placement supporting components from 01005 passive elements to complex BGAs with over 1932 I/Os

-

Advanced Assembly Techniques: Experience with µBGAs, 0.24mm pitch ICs, and challenging package types

-

Comprehensive Inspection Suite: In-line SPI, 3D AOI, X-ray inspection, and automated testing capabilities

-

Specialized Processes: Press-fit technology, conformal coating, selective soldering, and repair/rework services

-

Testing and Validation: Full functional testing, in-circuit testing, Sonda zburătoare, and burn-in capabilities

The UGPCB Advantage: Beyond Technical Specifications

While advanced equipment forms the foundation of UGPCB’s manufacturing capability, our true differentiation lies in the strategic integration of technology, expertise, and customer-focused service.

Proactive Engineering Support

UGPCB’s engineering team engages early in the design process to identify potential manufacturing challenges and optimize designs for production. Noastre DFM (Proiectare pentru producție) and DFT (Design for Testability) analysis helps clients avoid common pitfalls, reducing time-to-market and improving first-pass yield. This collaborative approach extends throughout the product lifecycle, with support for engineering change management ensuring smooth transitions from prototype to volume production.

Rigorous Quality Assurance

Quality at UGPCB extends beyond simple inspection to encompass a comprehensive quality management system that includes statistical process control, supplier qualification, and continuous improvement initiatives . Our commitment to quality is evidenced by our ability to consistently produce boards that meet Clasa IPC 3 and higher reliability standards , suitable for the most demanding applications including aerospace, dispozitive medicale, and industrial systems.

Material and Supply Chain Expertise

UGPCB robust material management system, supported by SAP integration , ensures component availability while managing cost and quality considerations. Our supplier qualification process and strategic inventory management provide clients with peace of mind, particularly important in the face of ongoing electronic component supply chain challenges.

Driving Innovation Through Advanced Manufacturing Technologies

UGPCB’s investment in the AOI horizontal paper insertion board unloader reflects our forward-looking approach to electronics manufacturing. This equipment forms part of our broader smart factory initiative that leverages industrial IoT concepts, data analytics, and automated material handling to create a responsive, efficient manufacturing environment.

The machine’s compatibility with AGV (Automated Guided Vehicle) sisteme enables seamless integration into automated production flows, supporting UGPCB’s vision of a fully connected digital factory. This automation strategy not only enhances operational efficiency but also provides customers with unprecedented traceability through comprehensive data collection at each process step.

Concluzie: Partnering for Success

In an industry characterized by rapid technological change and intensifying global competition, UGPCB represents a stable, innovative, and quality-focused manufacturing partner. Our investment in advanced equipment such as the AOI horizontal paper insertion board unloader demonstrates our commitment to providing clients with manufacturing services of the highest caliber.

Whether you require complex multilayer PCBs, challenging PCBA assemblies, sau complete box-build services, UGPCB possesses the technical expertise, quality systems, and manufacturing capability to bring your electronic products to life with precision and reliability.

Experience the UGPCB difference – where advanced technology, proven expertise, and unwavering quality commitment combine to deliver exceptional value. Contact us today to discuss how our comprehensive PCB and PCBA manufacturing solutions can accelerate your product development timeline while ensuring the highest standards of quality and reliability.

LOGO UGPCB

LOGO UGPCB