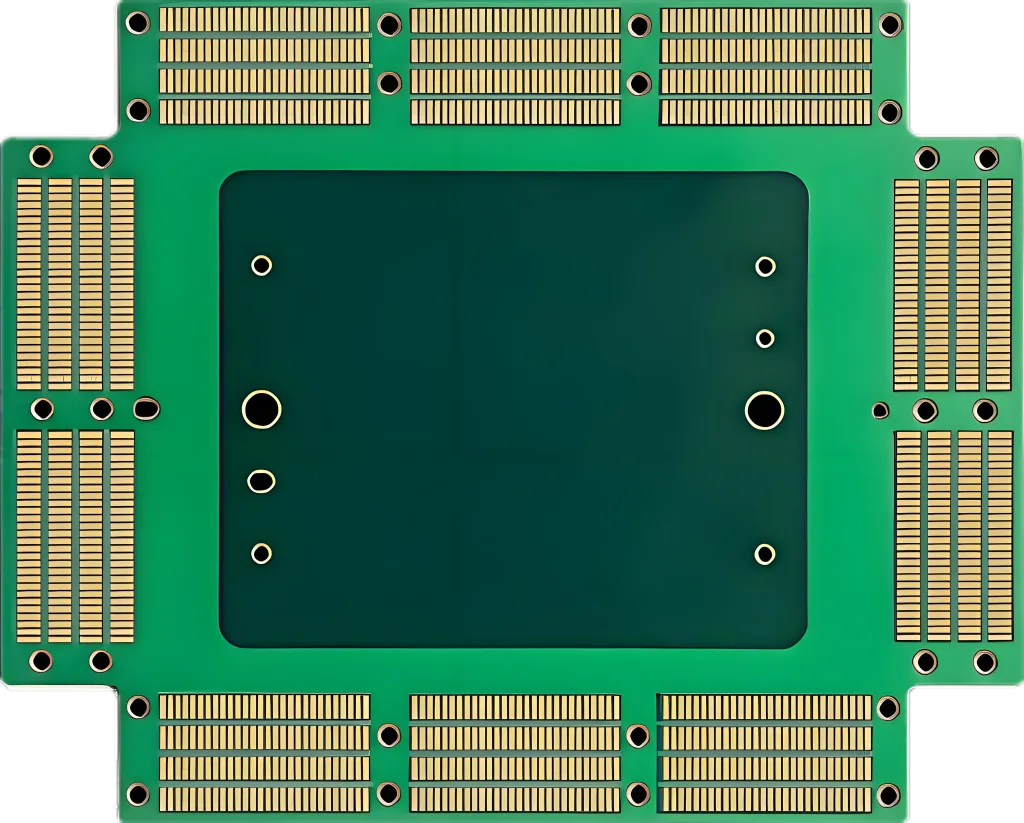

Введение в 58-слойную плату Eate Load Load

58-х слоя съел (Автоматизированное испытательное оборудование) Загрузка платы-это высокая плотность, многослойный печатная плата спроектировано для передачи точной передачи сигнала и долговечности в требованиях тестирования. Разработано с расширенными параметрами, Он обеспечивает оптимальную производительность в высокочастотных и мощных приложениях.

Ключевые спецификации

-

Слои: 58

-

Размеры: 17.2″ x 17.8″

-

Толщина: 230 мил

-

Материал: FR4 TG185

-

Минимальный размер отверстия: 5 мил

-

BGA -интервал: 0.8 мм

-

Соотношение сторон: 23.4:1

-

Расстояние для тренировки: 7 мил

-

Пофв (Нанесенный наполненным через): Да

-

Назад бурение: Нет

-

Поверхностная отделка: Eneg+Tg+только

Дизайн и структурные особенности

Критические соображения дизайна

-

Высокий уровень слоя: 58-слояная структура поддерживает сложную маршрутизацию для взаимодействия высокой плотности (ИЧР), Минимизация потери сигнала.

-

Выбор материала: FR4 TG185 обеспечивает тепловую стабильность (до 185 ° C температура перехода стекла), критическое для мощных применений.

-

Точное бурение: А 5 Мил минимальный размер отверстия и 23.4:1 Соотношение сторон, необходимо для BGA (0.8 мм шаг) Интеграция компонентов.

-

Целостность сигнала: Контролируемый импеданс и 7 Промежуточное расстояние в Mil Drill to-Copper уменьшает перекрестные помехи и электромагнитные помехи (Эми).

Уникальные структурные преимущества

-

Технология POFV: Повышается через надежность путем заполнения и покрытия вага, Улучшение тепловых и механических характеристик.

-

ENEG+TG+ENIG Surface Finish: Комбинирует электрополосное никелевое золото (Энэг) и погружение золота (СОГЛАШАТЬСЯ) Для превосходной коррозионной стойкости и припадения.

Производительность и приложения

Операционные принципы

Печатная плата облегчает точную маршрутизацию электрического сигнала через 58 слои, Использование диэлектрических свойств FR4 TG185 для поддержания целостности сигнала. POFV обеспечивает надежные соединения в среде высокого стресса, В то время как оптимизированное соотношение сторон поддерживает стабильные высокочастотные операции.

Ключевые показатели производительности

-

Тепловое сопротивление: Выдерживает температуру до 185 ° C.

-

Механическая стабильность: Высокий материал TG предотвращает расслоение при термическом велосипеде.

-

Скорость сигнала: Диэлектрический материал с низким потери.

Основные варианты использования

-

Автоматизированное испытательное оборудование (ЕЛ): Используется в системах полупроводникового тестирования для проверки ICS и микропроцессоров.

-

Аэрокосмическая и защита: Развернуто в радарных и коммуникационных системах, требующих высокой надежности.

-

Телекоммуникации: Поддерживает инфраструктуру 5G и высокоскоростную передачу данных.

-

Автомобильная электроника: Интегрируется в ADAS (Расширенные системы помощи водителю) и модули питания EV.

Производственный процесс и обеспечение качества

Производственный рабочий процесс

-

Подготовка материала: FR4 TG185 Ламинаты вырезаны до 17,2″ x 17.8″ размеры.

-

Лазерное сверление: Создает 5 Мил Микровий с 23.4:1 Соотношение сторон.

-

Покрытие и наполнение: Технология POFV применяет медное покрытие к заполненным вагам.

-

Слой стек: 58 слои выровняются и связаны под высоким давлением.

-

Поверхностная отделка: ENEG+TG+ENIG COTPATE применяется для защиты от коррозии.

-

Тестирование: Электрическая непрерывность, импеданс, и выполняются испытания на тепловые стресс.

Стандарты контроля качества

-

IPC-6012 Класс 3: Обеспечивает надежность для суровых средств.

-

Контроль импеданса: ± 10% допуск поддерживается.

Резюме преимуществ

-

Проект высокой плотности: Поддерживает сложные схемы в компактных пространствах.

-

Тепловая устойчивость: FR4 TG185 обеспечивает стабильность в экстремальных условиях.

-

Прецизионная инженерия: 5 MIL отверстия и 0,8 мм BGA -расстояние Включите миниатюрную интеграцию компонентов.

-

Универсальные приложения: От полупроводникового тестирования до 5G инфраструктуры.

Эта печатная плата сочетает в себе передовую конструкцию, Строгие стандарты производства, и надежные материалы для удовлетворения потребностей критически важной промышленности.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ