Precision Circuit Imaging & Etching Technology

UGPCB Factory demonstrates exceptional process control in circuit patterning and etching. For standard PCB production, we consistently achieve:

- Laser Direct Imaging (LDI) replacing traditional photolithography masks, enabling digital file-based exposure with ±5μm alignment accuracy

- Alkaline etching process ensuring clean line edges with ±15% line width control (industry-leading tolerance)

- Expertise in handling various copper thicknesses (1oz-6oz) with minimized side-etching

High-Precision Drilling & Hole Metallization

Our drilling capabilities cover:

- Mechanisches Bohren for 0.4mm-3.0mm boards with ±0.025mm hole size tolerance

- Laserbohrung down to 0.1mm microvias

- Hole metallization Erreichen >20μm uniform copper plating through advanced chemical deposition and electroplating

- Special processes for 8:1 Zu 10:1 aspect ratio requirements

Multilayer Lamination & Interlayer Alignment

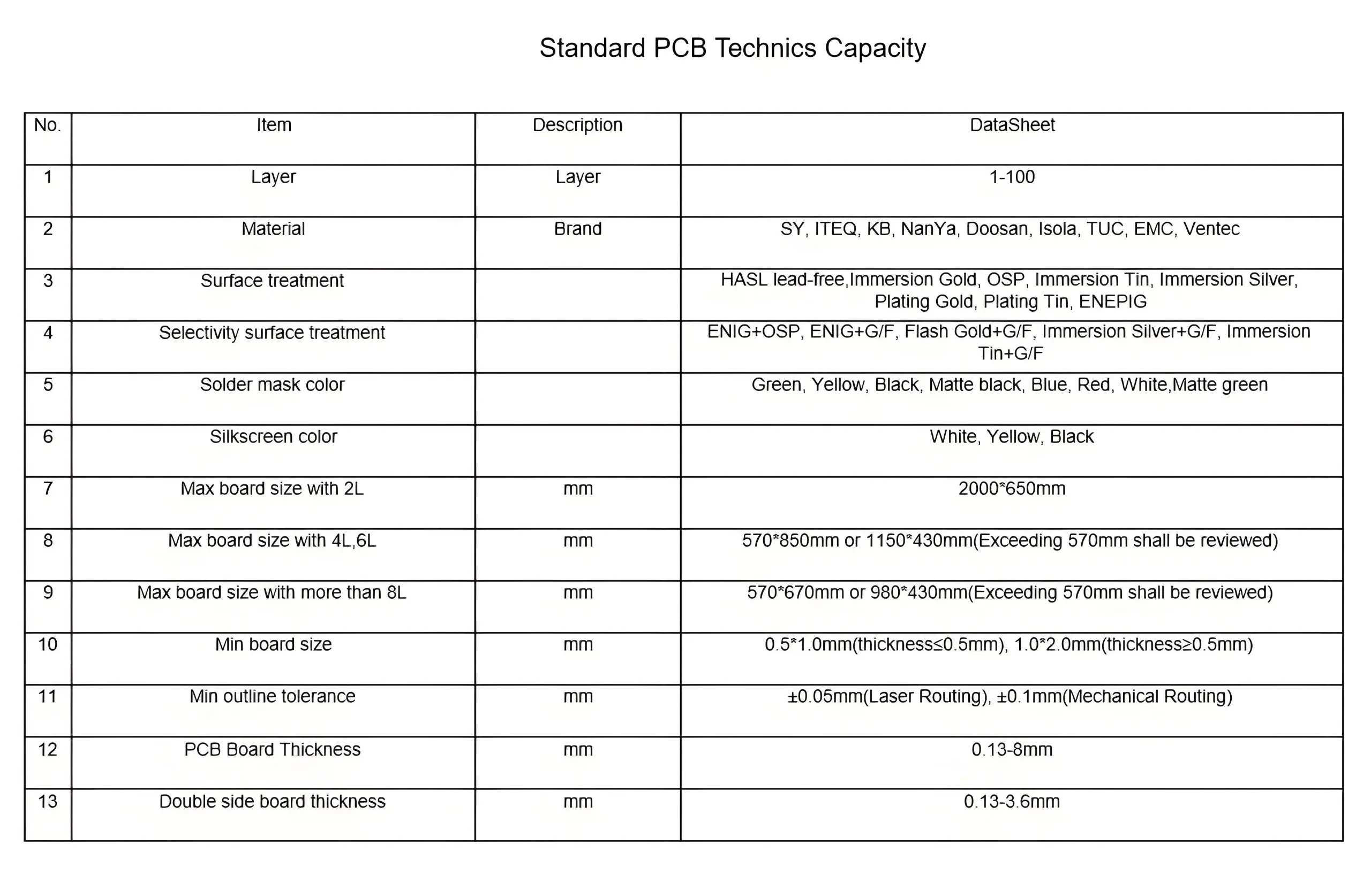

- Up to 100-layer PCB fabrication using FR-4 Grade A materials

- Precision lamination with ±15um layer-to-layer alignment

- Temperature/pressure/time-controlled processes preventing delamination

- Options for high-Tg materials, high-speed laminates, and heavy copper up to 1000μm

Lötmaske & Surface Finish Options

- Solder mask colors: Green/Blue/Red/Black with 0.08mm minimum solder bridge

- Oberflächenbewegungen:

- Bluten (Heißluftlötes Leveling)

- ZUSTIMMEN (Elektrololes Nickel -Eintauchgold)

- Immersion Tin/Silver

- OSP (Bio -Lötlichkeitsschutz)

Comprehensive QC & Testing Systems

- AOI -Inspektion: High-resolution defect detection for line/space, Pads, shorts/opens

- Impedanzkontrolle: ±10% tolerance for high-speed/RF applications

- Elektrische Tests: Fliegende Sonde & fixture-based continuity verification

- Reliability Testing: Thermoschock, humidity resistance, flexural testing

Process Capability & Stabilität

- CPK >1.33 (4A) across critical processes, reaching 1.67 (5A) in key areas

- Line width control within ±15% (vs industry 20% Standard)

- Statistical process control (SPC) ensuring consistent production quality

PCBA One-Stop Services

- SMT Assembly: 01005 component handling with ±0.03mm placement accuracy

- Erweiterte Verpackung: BGA/Micro BGA/PoP support with X-ray inspection

- DFM Support: Impedance calculation, Stapeldesign, manufacturability analysis

Branchenanwendungen & Kontakt

Serving consumer electronics, Industrielle Steuerungen, Telekommunikation, medizinische Geräte, and automotive sectors with tailored PCB solutions. Visit our website for process capability reports and free DFM consultation.

UGPCB-LOGO

UGPCB-LOGO

WeChat

Scannen Sie den QR-Code mit WeChat