Wir treiben die Revolution in der Leiterplattenfertigung voran: UGPCB Introduces Nationally Certified PE19-3052 Inline Plasma Desmear System

In the era of high-speed, Elektronik mit hoher Dichte, the reliability of a high-performance Leiterplatte (Leiterplatte) begins in the microscopic world invisible to the naked eye. The cleanliness of drilled hole walls is fundamental, directly determining the quality of subsequent metallization and forming the cornerstone of a PCB’s electrical performance and long-term reliability. Traditional chemical wet desmear processes are increasingly becoming a bottleneck for high-end Leiterplattenherstellung in terms of environmental impact, kosten, and consistency.

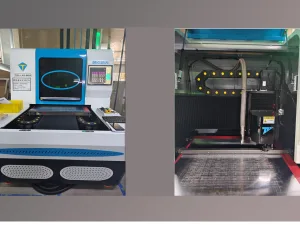

Heute, this paradigm has been fundamentally transformed. As a leading PCB and PCBA-Hersteller, UGPCB has proactively integrated the “PE19-3052 Fully Automatic Inline Plasma Desmear System,” developed by Zhuhai Hengge Microelectronic Equipment Co., Ltd. The technology underpinning this equipment has been recognized by China’s Ministry of Industry and Information Technology (MIIT) as part of the inaugural list of “Advanced and Applicable Technologies,” marking a landmark achievement in the PCB industry’s green and high-end transformation. This is more than an equipment upgrade; it is a firm commitment from UGPCB to providing “high-reliability PCB solutions” and advancing next-generation advanced PCB manufacturing processes.

Part 1: Breaking with Tradition: The Technological Leap from Chemical Wet to Physical Dry Processing

In the manufacturing of multilayer and high-layer count PCBs, heat from drilling creates a layer of insulating “smear” on the hole wall epoxy resin. Incomplete removal leads to poor hole metallization, causing potential critical defects like open circuits and board delamination. For decades, the industry relied on the wet process of permanganate chemical desmear—a lengthy sequence involving “swell → desmear → neutralize” Schritte, generating vast amounts of COD (Chemical Oxygen Demand) laden wastewater.

The Hengge PE19-3052 system brings a fundamental revolution. It employs dry plasma treatment technology, using Radio Frequency (Rf) energy to ionize process gases (z.B., mixtures of oxygen, Stickstoff, carbon tetrafluoride), creating highly active plasma. These energetic particles bombard the hole walls, precisely stripping and vaporizing the resin smear through physical sputtering and chemical reactions, achieving simultaneous cleaning and activation.

A comparative formula highlights its superiority:

Traditional Wet Process Cost (C_wet) ≈ Chemical Costs + Water Treatment Costs + Energy Costs + Time Costs + Safety/Compliance Costs

Plasma Dry Process Cost (C_dry) ≈ Electricity Cost + Process Gas Cost

When C_dry << C_wet and quality factor Q_dry ≥ Q_wet, technological substitution becomes inevitable.

The system adopted by UGPCB is the optimal implementation of this formula. Integrated directly at the front end of existing Plated Through-Hole (PTH) lines, it enables seamless PCB automated production, completely replacing the traditional wet desmear stage and eliminating the use and associated risks of strong oxidizers at the source.

Part 2: The PE19-3052 System: Defining Precision and Efficiency in High-End PCB Fabrication

The PE19-3052 is not merely a functional replacement; it is a high-precision production unit engineered for modern smart PCB-Fabriken. Its core design tackles the industry challenge of uniform treatment for large-format, high-layer-count boards.

1. Superior Hardware Design Ensures Consistency

The core plasma chamber utilizes aerospace-grade seamless welding, ensuring exceptional vacuum integrity with a leak rate below 10 mt/min, forming the foundation for a stable plasma environment. Its innovative “multi-grid electrode structure” and high-efficiency RF electrode design achieve over 85% treatment uniformity even for oversized panels (easily handling large boards like server motherboards), decisively solving the pain point of disparity between edge and center results. One-piece electrode forming and removable panel designs further ensure long-term operational stability and ease of maintenance.

2. Deep Integration of Intelligence and Automation

The system perfectly aligns with Industry 4.0 Prinzipien. It automatically synchronizes with PTH line speed for unattended continuous production. Integrated high-precision sensors and an intelligent control system monitor and dynamically adjust dozens of parameters—process gas mixture, RF power, vacuum level—in real-time, ensuring every board and every hole meets stringent preset standards. This provides critical data support and closed-loop process control capability for UGPCB’s fully digitalized Leiterplattenfertigung ecosystem.

3. Inherent Green Manufacturing for the Future

Green manufacturing is a core competency for high-end PCB production. The PE19-3052 system achieves pollution and carbon reduction at the source. According to MIIT-disclosed techno-economic indicators, for a PTH line with a daily capacity of 10,000 square feet, this technology can save approximately 1.79 million RMB annually in operational costs alone. More significantly, it enables:

-

Zero Chemical Wastewater Discharge: Permanently solving the permanganate wastewater challenge.

-

Exceptionally Low Energy Consumption: Significantly lower compared to the multiple rinse and heating tanks of traditional processes.

-

Enhanced Safety: Creating a work environment free from chemical exposure risks for operators.

Part 3: Empowering Products: How UGPCB Leverages Cutting-Edge Technology to Enhance Customer Value

The integration of plasma desmear and similar technologies is not an isolated investment but a strategic upgrade of UGPCB’s overall high-precision PCB manufacturing capability, translating directly into tangible customer value.

1. Overcoming Reliability Barriers in High-End Product Manufacturing

This system is particularly suited for communication equipment PCBs, server PCBs, semiconductor test boards, and high-frequency high-speed PCBs with near-zero defect tolerance. It perfectly handles various high-performance materials (including FR-4, Mid/Low/Very Low Loss high-speed PPO/PPE substrates, Polyimid), providing impeccable hole metallization for customers in 5G infrastructure, AI -Server, data center switches, und Automobilelektronik. With the server PCB market projected to grow at a 9.9% CAGR driven by AI and cloud computing, UGPCB secures a quality leadership position with this technology.

2. Driving Overall PCBA Yield and Performance

Superior PCB fabrication is the prerequisite for high-quality PCBA-Montage. The ultimate cleanliness and activation of hole walls result in superior copper adhesion and more uniform plating, which directly translates to:

-

Higher PCBA Solder Yield: Reducing defects like post-solder hole wall separation (blowholes) caused by poor copper adhesion.

-

Stronger Electrical Connection Reliability: Lower hole resistance and more stable impedance enhance signal integrity and long-term product stability.

-

Support for Advanced Packaging: Providing a reliable microvia foundation for the High-Density Interconnect (HDI) structures required by advanced PCBA packaging like embedded die and board-level fan-out (Fan-out).

3. Accelerating R&D and Providing One-Stop Solutions

For clients developing cutting-edge products, UGPCB leverages the enhanced process windows from recent technological upgrades to assist in validating and prototyping new materials and designs, significantly shortening development cycles. From high-layer count PCB circuit board manufacturing to backend SMT assembly and PCBA testing, UGPCB possesses the robust technical foundation to offer comprehensive one-stop PCBA services, ensuring quality consistency and control across the entire product chain.

Part 4: Beyond Equipment: The Deeper Rationale for Choosing UGPCB as Your Strategic Partner

The investment in nationally certified technology like the PE19-3052 profoundly reflects UGPCB’s corporate DNA and long-term vision.

1. Unwavering Pursuit of Technological Leadership

UGPCB regards technological innovation as its lifeline. Adopting the PE19-3052 represents a deep alignment with frontier technology endorsed by national-level “Little Giant” enterprises like Hengge and authoritative experts from the China Printed Circuit Association (CPCA). We possess not just equipment, but continuously evolving process know-how and the capability to solve the most complex manufacturing challenges.

2. Firm Commitment to Green and Sustainable Development

We are dedicated to building a green PCB factory. The application of plasma desmear technology is a key component of UGPCB’s systematic energy-saving and emission-reduction strategy. Combined with our plant-wide intelligent energy management and waste resource recovery systems, we provide green electronics manufacturing services that meet international environmental standards and supply chain audit requirements.

3. Trustworthy Scalable Delivery Capability

As a manufacturer consistently ranked among China’s top PCB-Unternehmen, UGPCB perfectly blends cutting-edge process technology with scalable, standardized production management. The efficiency gains and cost optimization from integrating the PE19-3052 and other advanced systems allow us to offer highly competitive pricing for PCB bulk production and ensure stable, timely delivery while guaranteeing top-tier quality—a core reason leading server and communication equipment manufacturers consistently choose us.

Abschluss

In the grand progression of PCB manufacturing towards precision and sustainability, UGPCB’s integration of advanced technological systems like the PE19-3052 represents not just a revolution in a critical production step, but a clear delineation of our future as a preferred PCB/PCBA manufacturing partner. We are armed with state-recognized frontier technology, supported by a deeply intelligent production framework, and driven by an unwavering commitment to superior quality and green development.

We invite clients across industries, especially partners in communications equipment, data centers, Automobilelektronik, and semiconductor testing with extreme demands for reliability and consistency, to visit the UGPCB facility. Witness firsthand how this revolutionary technology safeguards your high-end products. Let’s collaborate to empower the next era of innovation with more precise, zuverlässig, and environmentally conscious circuit interconnection solutions.

UGPCB-LOGO

UGPCB-LOGO