Spécifications fondamentales pour la fabrication du pochoir

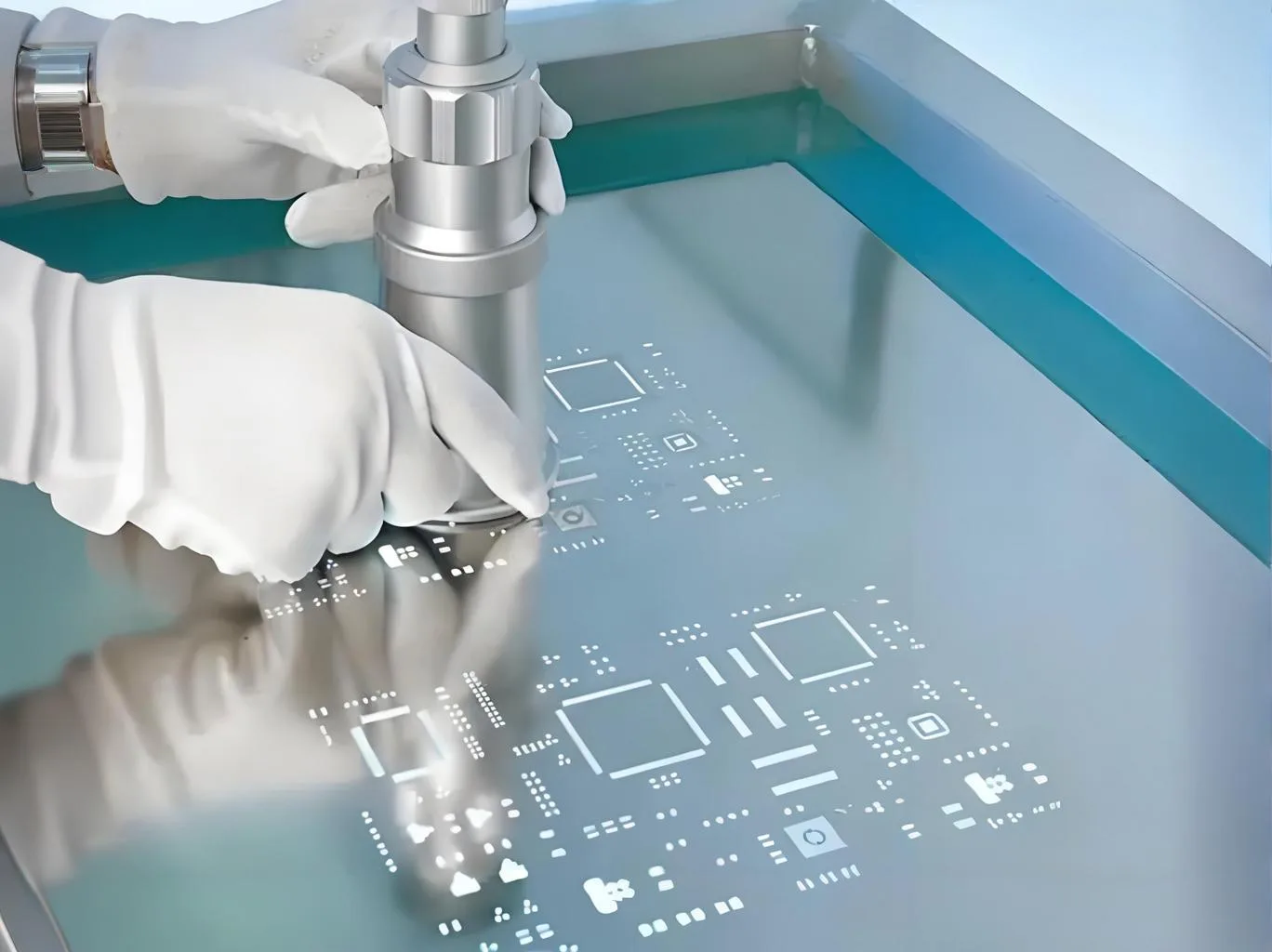

Dans Fabrication SMT processus, La précision d'ouverture du pochoir détermine directement la qualité de l'impression de pâte de soudure. Suivre les normes IPC-7525, Nous analysons les paramètres d'ingénierie essentiels:

Modèle de matrice de tension tridimensionnelle

Utilisation de la formule de mécanique des matériaux:

T = (E × Δl)/L

*(Où E = Module de Young, 200GPA pour l'acier inoxydable)*

-

Tension initiale ≥40 n / cm pour les nouveaux pochoirs

-

Seuil de remplacement ≤32N / cm

-

3× 3 points de mesure de la matrice (Comme le montre la figure 1)

Les données empiriques révèlent:

-

12% diminution du taux de libération de la pâte de soudure lorsque la tension passe de 40 n / cm à 35 n / cm

-

0.03Augmentation de la déviation positionnelle MM

Principes de guide d'onde pour la conception de la marque fiduciaire

Les fiduciaires semi-gravés remplis d'époxy noir obtiennent une réflectivité optimale (0.3-0.5 lux). À travers les équations de Fresnel:

R = [(n₁ – n₂)/(n₁ + n₂)]²

*(n₁ = 1,0 pour l'air, n₂ = 1,55 pour l'époxy)*

Réflectivité théorique: 18.3%, Idéal pour les systèmes de vision industrielle.

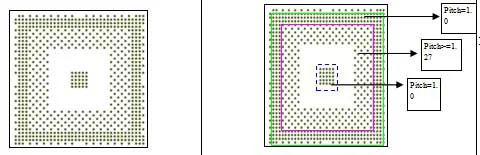

Matrice de conception d'ouverture du composant sans plomb

Ratio d'or pour les composants de la puce standard

0603 Packages:

-

0.85Pads carrés de coupe intérieure MM

-

Profondeur concave φ = y₁ / 3 = 0,26 mm

-

Compensation de la zone K = 1,1:

A = π(D₁ / 2)² = π ×(0.86/2)² = 0,58 mm²

0805 Packages:

-

1.1Distance de coupe intérieure mm

-

Rayon concave φ = 0,42 mm

-

1.46× Facteur d'agrandissement de la zone

Optimisation de la topologie pour les composants spéciaux

1206 Condensateurs de tableau:

-

Décalage de l'axe x Δx = 0,1 mm

-

Aperture reduction coefficient η=0.12

-

Largeur finale x₂ = x₁-η = 0,45 mm

Cette conception asymétrique compense la déformation thermique pendant la reflux, réduisant les tombes de la tombe par 37%.

Technologies de contrôle de l'ouverture de précision

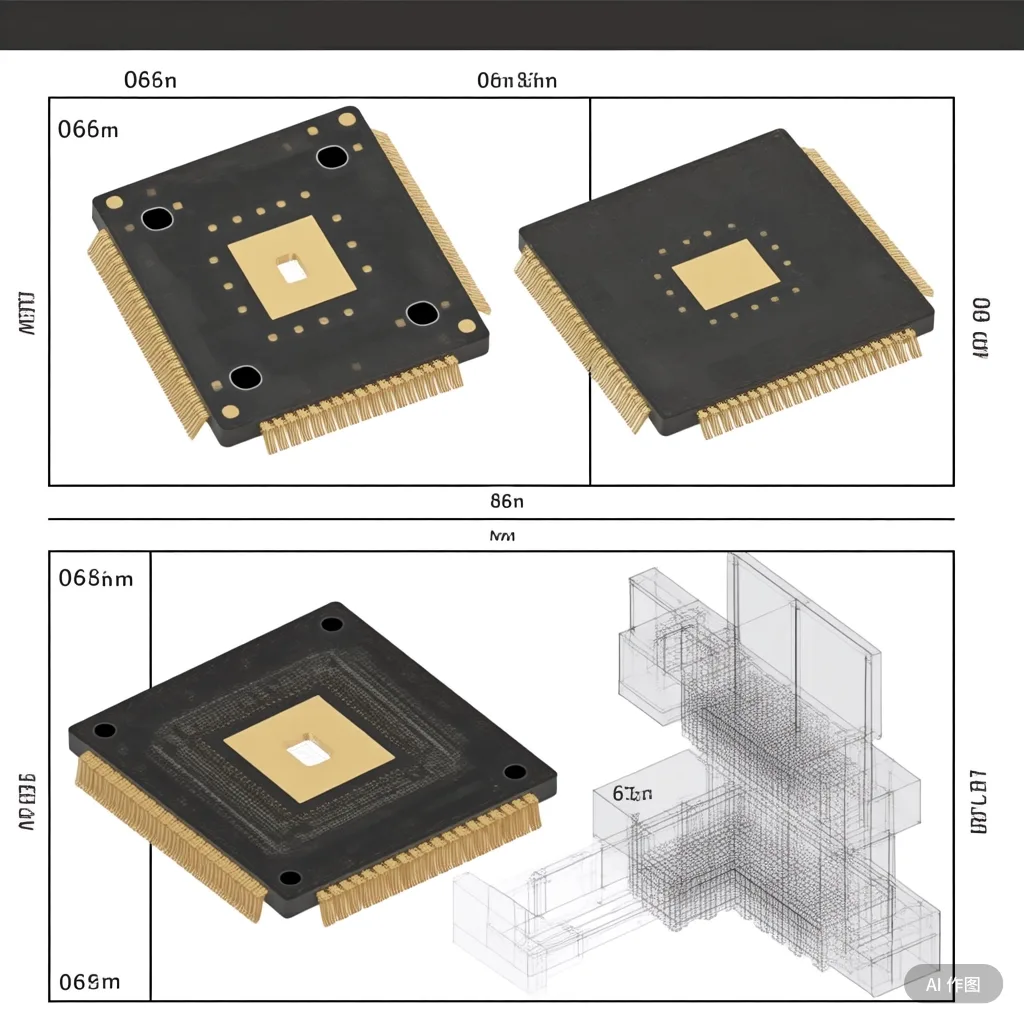

Algorithme de pont QFP

0.5MM Pitch QFP:

-

Largeur du pont w₁ = 0,2 mm

-

Ratio de segment l₁:L₂ = 1:0.7

-

Rayon de filet r = 0,1 mm

Les simulations CFD montrent:

-

Le taux de libération de la soudure s'améliore de 82% à 91%

-

Les défauts de pontage réduisent 68%

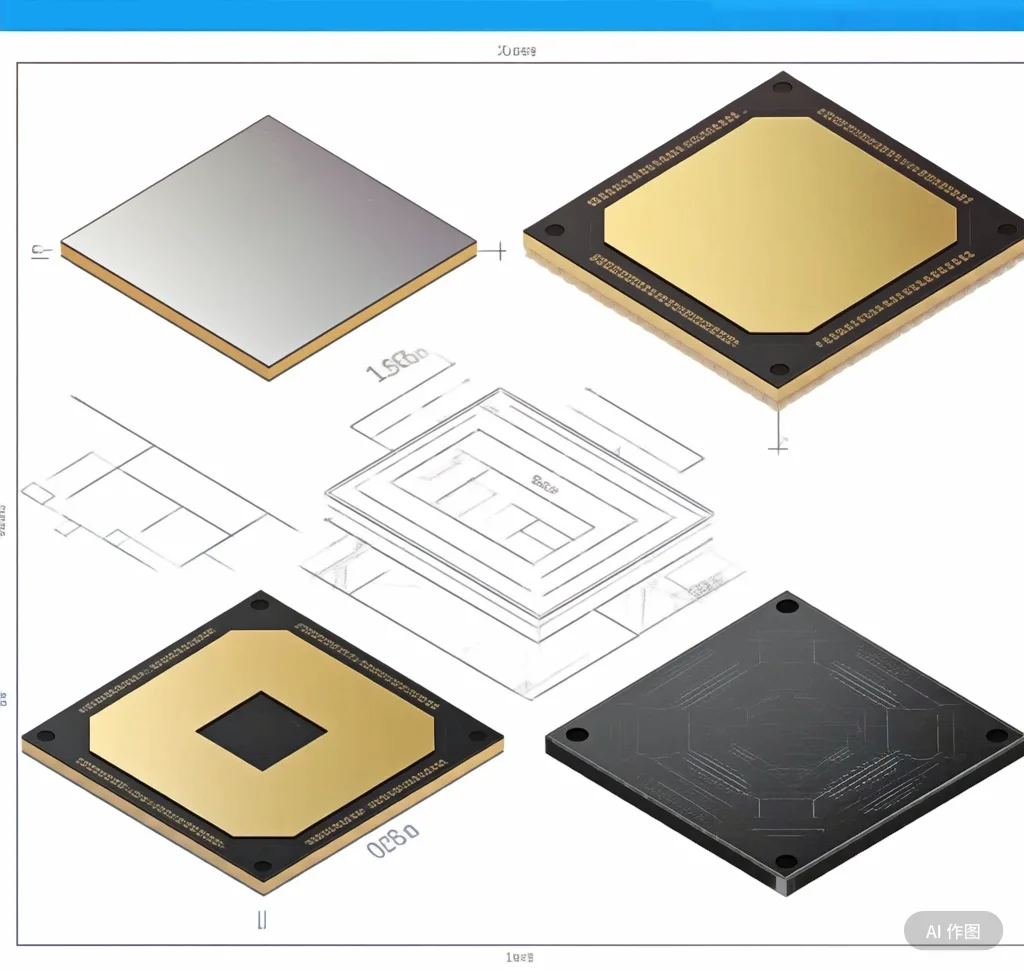

Stratégie de contrôle du gradient BGA

Contrôle du gradient à quatre couches:

-

Couche externe: φ₁ = 0,42 mm (tableau irrégulier)

-

Deuxième couche: Maintenir φ = 0,42 mm

-

Troisième couche: φ₂ = 0,42 mm (via l'autorisation)

-

Couche intérieure: φ₁ = 0,42 mm

Taux de réduction du diamètre:

d = (F-f₁)/Φ = 16%

Calcul du rapport zone:

Ratio de zone = zone d'ouverture / zone murale = 0,42² /(π × 0,42 × 0,13) = 3.1

*(Rencontre IPC 2.5-3.5 plage optimale)*

Systèmes de vérification d'ingénierie

Test de tension de neuf points

3D Coordonnées des exigences:

-

Espacement de l'axe X = (Longueur de pochoir – 100mm)/2

-

Espacement de l'axe Y = (Largeur de pochoir – 80mm)/2

-

Déclaration de bord ≥50 mm

Matrice de validation de la précision de l'ouverture

20 Les mesures d'ouverture aléatoire doivent satisfaire:

-

Déviation x / y ≤ ± 0,02 mm

-

Erreur de rotation ≤ 0,5 °

-

Tolérance au formulaire ≤0,03 mm

Perspectives de fabrication avancées

Avec 01005 adoption de paquets, La fabrication du pochoir atteint:

-

± 1 μm de précision

-

<3° Contrôle du conique

-

Rampe<0.2μm de rugosité de surface

Les systèmes alimentés par AI permettent:

-

Optimisation des paramètres en temps réel

-

± 3% Contrôle du volume de soudure

-

Assemblage de micro-pass fiable

Conclusion

Ce cadre technique comprenant 21 Les paramètres critiques améliorent le rendement des premiers pass par 15%+ Grâce à un contrôle optimisé des tensions et à la conception du gradient BGA.

LOGO UGPCB

LOGO UGPCB