UGPCB 8 couches 1 + n + 1 PCB HDI: Un guide complet

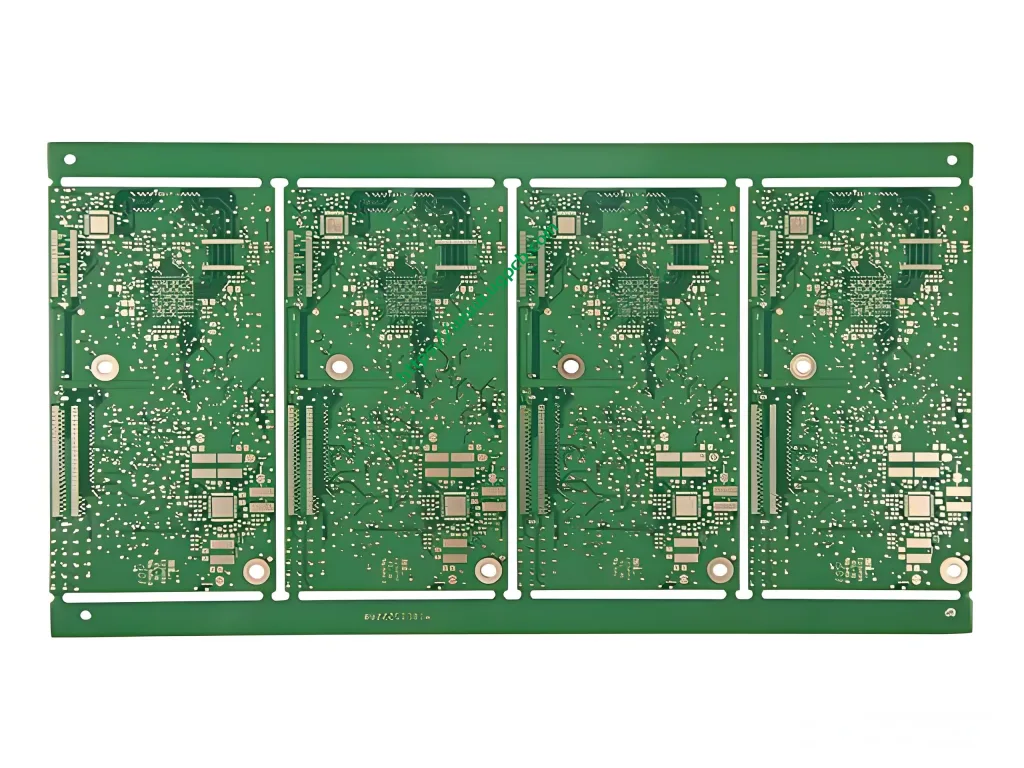

In the relentless pursuit of miniaturization and enhanced performance in electronics, Interconnexion à haute densité (IDH) PCB have become the cornerstone. UGPCB’s 8-Layer 1+N+1 HDI product represents a sophisticated solution for designers pushing the boundaries of what’s possible. This article provides a detailed look at this advanced circuit imprimé technologie.

What is an 8-Layer 1+N+1 HDI PCB?

An 8-Layer 1+N+1 HDI PCB is a specific type of high-density interconnect board. The nomenclature “1+N + 1” describes its microvia build-up structure.

-

The First and Last ‘1’: These represent a single layer of high-density microvias on the top and bottom surfaces of the board. These microvias are typically created using laser drilling.

-

The ‘N’: This represents the core of the board, which in this case is a standard 6-layer carte PCB multicouche (making the total 8 couches). The core contains through-holes or buried vias that connect the internal layers.

This structure allows for a very high number of interconnections in a compact space, making it ideal for complex, space-constrained Conceptions de PCB essential for modern microelectronic products.

Key Design Features and Specifications

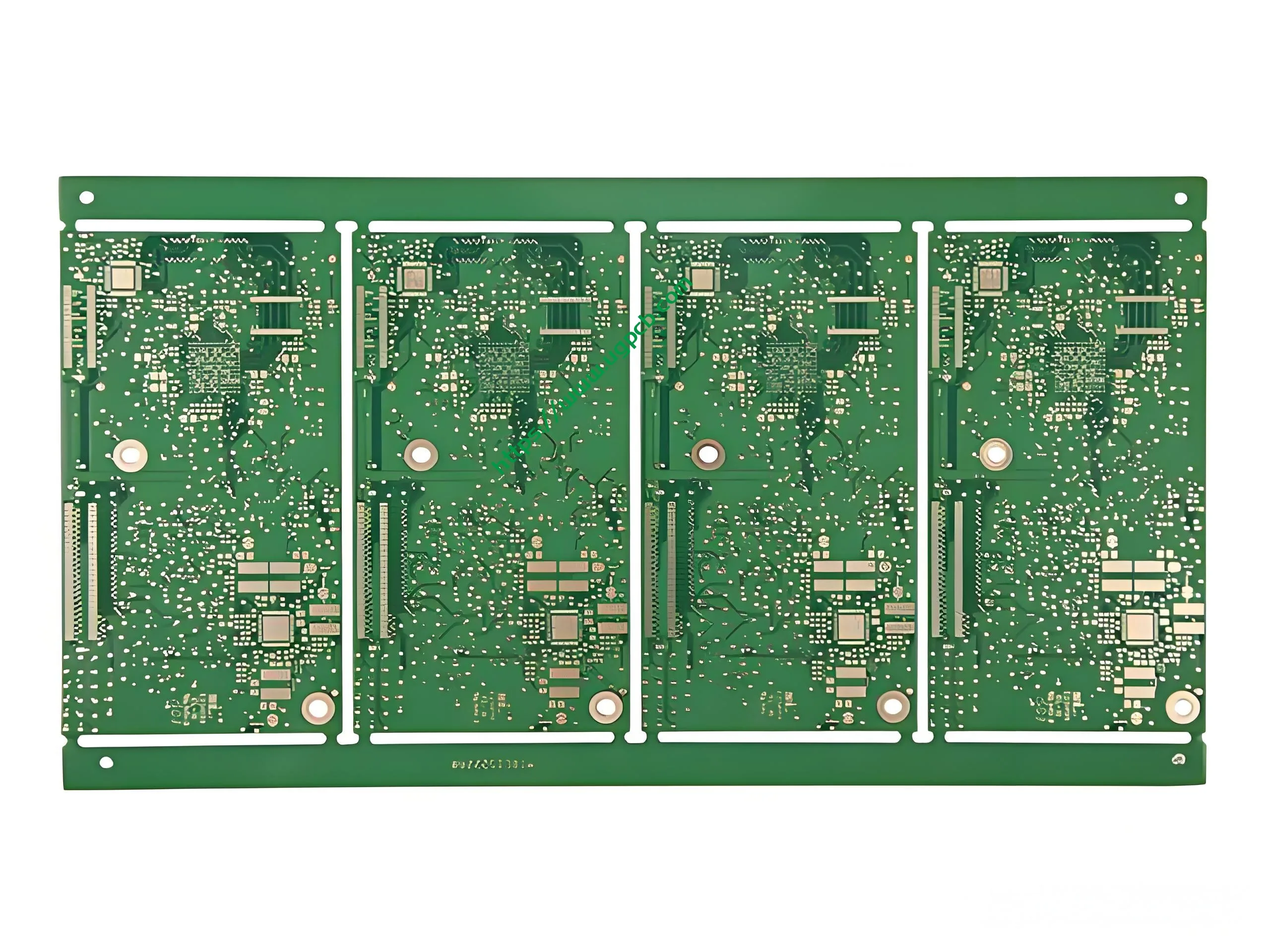

UGPCB manufactures this HDI PCB with precision, adhering to the following critical specifications:

-

Matériel: High-Tg FR-4, a robust and reliable laminate offering excellent thermal and mechanical stability.

-

Épaisseur du panneau: A finished thickness of 0.8mm, supporting slim product profiles.

-

Poids du cuivre: 1 once (35µm) for inner layers and 0.5 once (17.5µm) pour les couches externes. This balance ensures good current carrying capacity while allowing for finer outer layer trace etching.

-

Finition de surface: Immersion Or (ACCEPTER) over an OSP (Conservateur de soudabilité organique) foundation. This combination provides a flat, durable surface for soldering and excellent shelf life.

-

Trace / espace minimum: 3 mil (0.075 mm), enabling high-density circuitry.

-

Minimum Hole Size: 0.2mm for mechanical drills and an ultra-fine 0.1mm for laser-drilled microvias.

How This HDI PCB Structure Works

Le “1+N + 1” architecture functions by creating a more efficient routing pathway. Instead of using large through-holes that consume valuable real estate on every layer, ce HDI PCB design utilizes microvias. These tiny laser-drilled holes connect only adjacent layers (par ex., L1 to L2, or L8 to L7). Ce “stacked” ou “staggered” via approach frees up routing channels on the inner layers, allowing for a much greater component density and more efficient signal paths, which is crucial for high-speed Assemblage PCBA.

Primary Applications and Use Cases

The primary application for this advanced HDI PCB is in sophisticated microelectronic products. Specific use cases include:

-

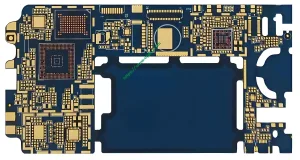

Technologie portable: Smartwatches, fitness trackers, and medical monitors.

-

Advanced Mobile Devices: Smartphones, comprimés, and ultra-portable laptops.

-

High-Density Medical Equipment: Miniaturized medical imaging and diagnostic devices.

-

Aerospace and Defense Avionics: Where reliability and size are paramount.

The Material Composition: FR-4 Laminate

The choice of FR-4 material is strategic. It provides an excellent balance of performance, coût, and manufacturability. For this 0.8mm thick HDI PCB, a high-grade FR-4 with a high glass transition temperature (Tg) is used to withstand the thermal stress of multiple lamination cycles and lead-free PCB soldering processes.

Performance and Structural Advantages

The structure of the 1+N+1 HDI board directly translates to significant performance benefits:

-

Intégrité du signal amélioré: Shorter interconnection paths reduce signal loss and propagation delay.

-

Improved Thermal Management: The dense via structure aids in heat dissipation.

-

Superior Reliability: The use of microvias reduces the risk of solder joint failure during thermal cycling.

-

Reduced Size and Weight: The core advantage of HDI technology, enabling smaller end products.

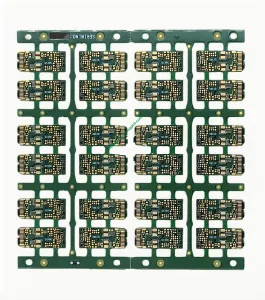

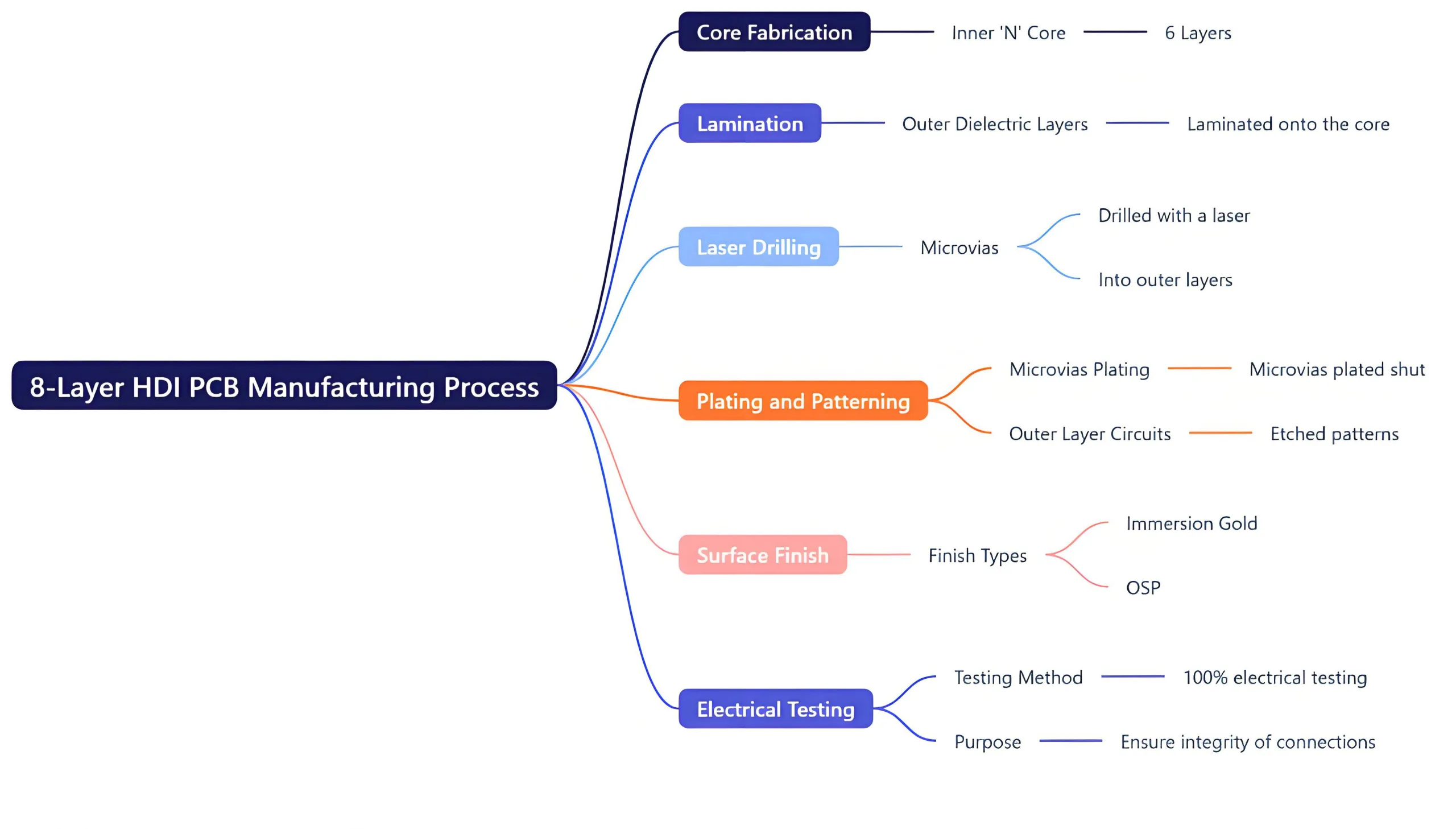

A Simplified Overview of the Production Process

The manufacturing of this HDI PCB is a multi-step, precision process:

-

Core Fabrication: The inner ‘N’ cœur (6 couches) is produced first.

-

Laminage: Outer dielectric layers are laminated onto the core.

-

Forage au laser: Microvias are drilled with a laser into the outer layers.

-

Plating and Patterning: The microvias are plated shut, and the outer layer circuits are etched.

-

Finition de surface: The Immersion Gold and OSP are applied.

-

Tests électriques: 100% electrical testing ensures the integrity of all connections.

Why Choose UGPCB for Your HDI PCB and PCBA Needs?

UGPCB’s expertise in manufacturing 8-Layer HDI PCBs offers distinct advantages for your project. Their capability to reliably produce boards with 3/3 mil lines and 0.1mm microvias positions them as a leader for complex PCB manufacturing. This makes them an ideal partner not just for Fabrication de circuits imprimés but also for a full turnkey PCBA service, ensuring a seamless transition from design to a finished, assembled product.

LOGO UGPCB

LOGO UGPCB