Système de traitement des effluents UGPCB: Setting New Benchmarks for Green Manufacturing in the PCB Industry

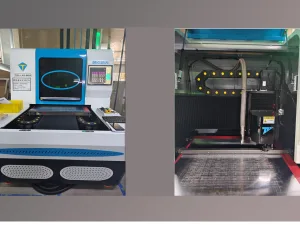

Equipment Overview and Core Technology Analysis

UGPCB employs a modular intelligent wastewater treatment system, specifically designed to address the high heavy metal and organic pollution characteristics of the PCB industrie. This system integrates three core technological modules: chemical precipitation, membrane separation, and IoT monitoring. It achieves the following:

-

Heavy metal removal rate ≥ 99.8% (compliant with GB21900-2020 Table 3 normes)

-

CODcr treatment efficiency of 92% (exceeding the “Electronic Industry Pollutant Discharge Standards”)

-

100% taux de récupération du cuivre (achieved through electrodeposition technology for resource recycling)

The system utilizes an IoT-based intelligent control system to monitor over 20 parameters in real time, including pH levels, heavy metal concentration, and flow rate. Data is uploaded to a cloud platform, habilitant:

-

Remote fault diagnosis (response time ≤ 15 minutes)

-

Intelligent optimization of chemical dosing (reducing chemical usage by over 30%)

-

Dynamic energy consumption adjustment (power consumption ≤ 3.5 kWh per ton of water treated)

Environmental Technology Advantages of UGPCB

Closed-Loop Resource Recycling System

-

Wastewater reuse rate of 85%: Achieved through a combination of reverse osmosis (RO) and ultrafiltration (UF) processus, with treated water quality meeting GB/T 19923-2005 standards for industrial water reuse.

-

Metal resource recovery: Annual recovery of 1,200 tons of copper, tin, and other metals, generating economic benefits of 24 million RMB (basé sur 2025 market prices).

IoT-Enabled Intelligent Operation and Maintenance

-

Equipment health prediction: Utilizes vibration sensors and AI algorithms to provide early warnings of potential failures up to 72 hours in advance.

-

Carbon emission management: Integrated carbon footprint calculation module displays real-time carbon emission data during the treatment process.

Certifications and Standard Leadership

-

OIN 14001 Certification du système de gestion environnementale

-

Certification UL (ECOLOGO® Environmental Label Certification)

-

Rohs conforme (meets EU Restrictions on Hazardous Substances Directive)

Environmental Practices in PCBA Production

Dans le PCB (Assemblage de la carte de circuit imprimé) phase, UGPCB has established a lead-free production system:

-

Use of lead-free solder: Employs Sn-Ag-Cu alloy with lead content < 0.1%

-

Exhaust gas treatment system: Combines activated carbon adsorption and catalytic combustion technologies to maintain VOC emissions below 10mg/m³

-

Electrostatic precipitators: Achieve particulate matter capture efficiency ≥ 99.9%

Industry Impact and Social Responsibility

Driving Industry Standard Upgrades

-

Participation in drafting the “China Electronics Circuit Industry Association Environmental Technology Standards”

-

Involvement in establishing energy consumption standards for PCB wastewater treatment (≤ 4.0 kWh per ton of water)

Green Supply Chain Development

Implementation of a traceability platform for PCB waste materials, enabling full-process tracking from raw materials to recycling.

Environmental Benefits Data

-

Annual reduction in emissions: COD 180 tons, ammonia nitrogen 25 tons, heavy metals 3.2 tons

-

Water conservation benefits: Annual reduction of 400,000 cubic meters in freshwater consumption

Future Technology Outlook

UGPCB is currently developing bio-electrochemical coupled treatment technology, with the following anticipated outcomes:

-

40% reduction in treatment costs (target achievement by 2026)

-

Achievement of microelectronic-grade pure water reuse (resistivity ≥ 18 MΩ · cm)

LOGO UGPCB

LOGO UGPCB