Материальная композиция

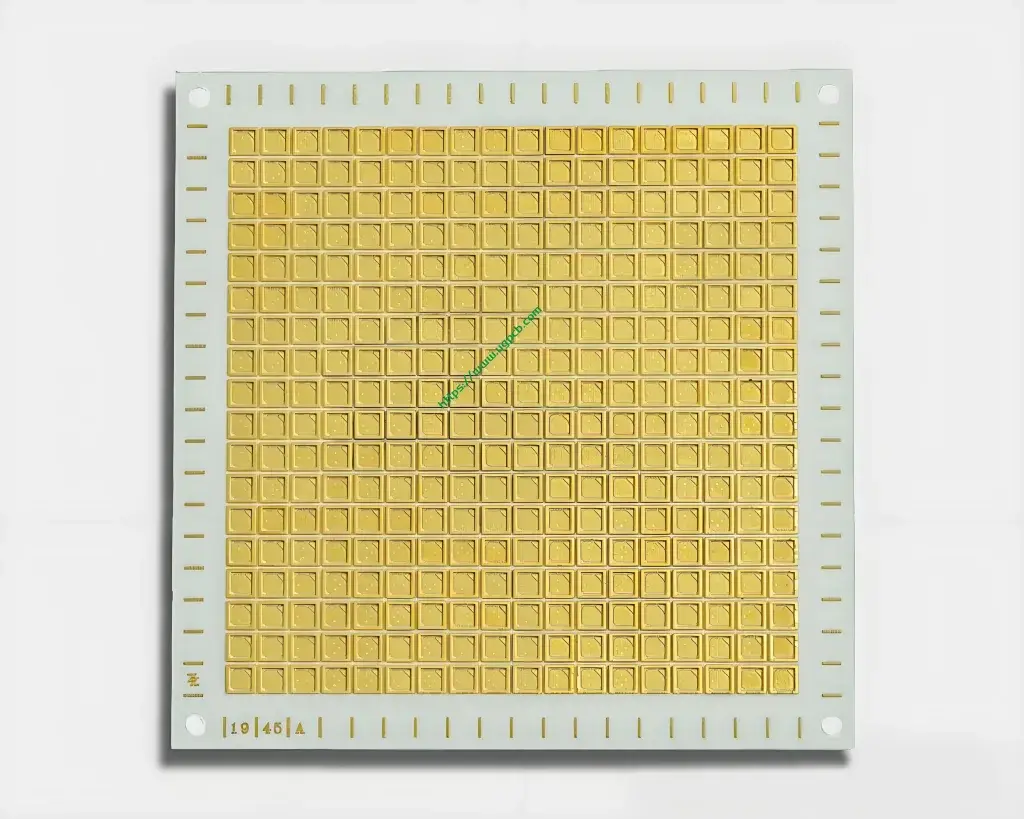

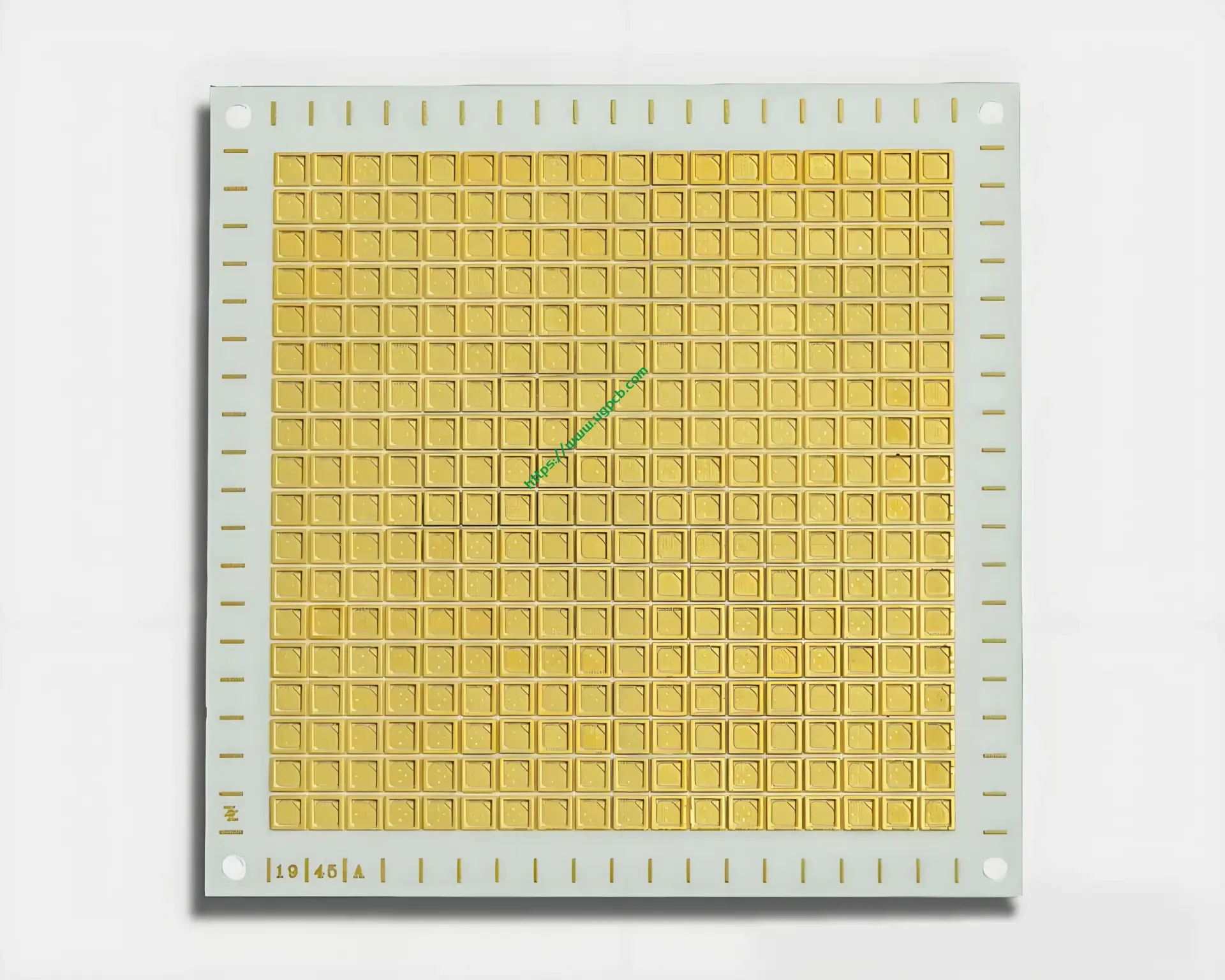

The DPC ceramic substrate is crafted from high-quality ceramic aluminium oxide. This material is renowned for its exceptional thermal conductivity, механическая прочность, и свойства электрической изоляции, making it ideal for applications requiring precise control and performance.

Характеристики производительности

With a finished thickness of 2.4mm and outer copper thickness of 2OZ, the DPC ceramic substrate offers robust structural integrity while providing ample conductivity. The white color and hard gold surface treatment not only enhance its aesthetic appeal but also ensure superior corrosion resistance and long-term durability. Its two-layer design further supports advanced circuitry configurations, catering to complex electronic applications.

Unique Features

One of the standout features of the DPC ceramic substrate is its УГКПБ ceramic bracket, a special process that integrates a ceramic bracket directly onto the substrate. This innovation enhances thermal management and structural support, crucial for maintaining optimal performance in demanding environments. The use of ceramic aluminium oxide as the base material also grants it high hardness and wear resistance, ensuring it performs reliably under extreme conditions.

Производственный процесс

The production of DPC ceramic substrates involves several meticulous steps:

Подготовка материала

High-purity ceramic aluminium oxide powder is meticulously processed to form the base layer.

Ламинирование

The ceramic layers are bonded together under controlled conditions to achieve the desired thickness and uniformity.

Circuitry Formation

Copper circuits are etched onto the substrate using advanced photolithography and etching techniques.

Обработка поверхности

The copper surfaces are coated with hard gold to enhance conductivity, коррозионная стойкость, и паяемость.

Assembly of Ceramic Bracket

The UGPCB ceramic bracket is precisely attached to the substrate, ensuring robust thermal and structural integration.

Заключительная проверка

Each substrate undergoes rigorous quality control checks to ensure it meets all specifications and performance standards.

Сценарии приложения

The DPC ceramic substrate finds extensive application in the LED industry, particularly as an LED substrate печатная плата. Its exceptional thermal conductivity helps dissipate heat efficiently, preventing LED components from overheating and prolonging their lifespan. The substrate’s high mechanical strength and electrical insulation properties make it suitable for use in high-power LED lighting systems, automotive headlights, and other demanding applications where reliability and performance are paramount.

Заключение

The DPC ceramic substrate, with its combination of advanced material composition, robust performance characteristics, unique features, meticulous production process, и универсальные сценарии применения, stands as a testament to the innovation and precision of modern electronics manufacturing. Its ability to support high-performance LED systems and withstand harsh operating conditions makes it an indispensable component in today’s technology-driven world.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ