UGPCB Standard 2-Layer Rigid PCB: Reliable 1.6mm FR-4 Circuit Boards for Demanding Applications

At the heart of modern electronics, а Печатная плата (печатная плата) acts as the foundational platform, interconnecting components and routing signals with precision. UGPCB Standard 2-Layer Rigid PCB, built with a robust 1.60ММ толщина и высокая производительность FR-4 TG150 material, represents the optimal balance of durability, Электрические характеристики, and cost-effectiveness for a wide range of applications. Этот double sided PCB is a proven solution for prototypes and medium-complexity electronic devices.

Product Definition & Классификация

Technical Classification:

-

По количеству слоев: Double-Sided PCB / Two Layer PCB

-

By Substrate Rigidity: Rigid PCB

-

Базовым материалом: Glass Epoxy (ФР-4) печатная плата

-

By Flammability Rating: UL94 V-0 (inherent to FR-4)

-

By Assembly Compatibility: Технология сквозного (ТТТ) and Surface-Mount Technology (СМТ) capable PCB.

This product is a double sided circuit board constructed with copper clad laminate on both sides of an insulating FR-4 core. Electrical connection between layers is achieved via plated through-holes (ПТХ). The 1.60мм (примерно 1/16 дюйм) толщина доски is an industry-standard, offering excellent mechanical stability.

Строительство & Материальные спецификации

Слой стек:

Этот 2 layer rigid PCB structure is as follows (top to bottom):

-

Top Solder Mask (Белый): Insulating layer to prevent solder bridges.

-

Top Copper Layer (1 унция, ~35µm): Etched to form conductive traces and pads.

-

Insulating Core Substrate (ФР-4, Tg150): Provides mechanical support and electrical insulation.

-

Bottom Copper Layer (1 унция, ~35µm): Etched to form bottom-layer circuitry.

-

Bottom Solder Mask (Белый): Insulating protective layer.

-

Легенда шелкографии (Черный): Component designators, logos, and markings.

Key Materials:

-

Base Laminate: FR-4 TG150. This denotes a flame-retardant glass-reinforced epoxy laminate with a Glass Transition Temperature (Тг) of 150°C. It offers superior mechanical strength, электрическая изоляция, and thermal reliability for a rigid printed circuit board, making it the industry’s most cost-effective choice.

-

Медная фольга: Standard 1-ounce (унция) Electro-Deposited copper for optimal conductivity and current carrying capacity.

-

Поверхностная отделка: Lead-Free Hot Air Solder Leveling (ХАСЛ). A cost-effective and reliable PCB surface finish that provides excellent solderability, good shelf life, and robust protection against oxidation.

-

Inks: High-quality photo-imageable white solder mask ink and durable black epoxy silkscreen ink.

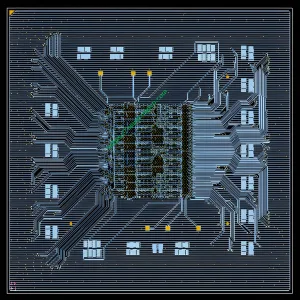

(Image Suggestion: Cross-sectional diagram of the PCB stack-up)

Alt Tag: Detailed cross-sectional diagram of a 2 layer rigid PCB showing copper, FR-4 core, and solder mask layers.

Рекомендации по проектированию & Operational Principle

Критические соображения дизайна:

-

Via Design: Maximize the routing space of your double sided дизайн печатной платы by strategically placing Plated Through-Holes (ПТХ) for inter-layer connections.

-

Ширина трассировки/расстояние: For 1oz copper, a standard minimum trace/space is 6mil/6mil (~0.15mm) to ensure reliable manufacturability and current capacity.

-

Прокладка & Hole Annular Ring: Ensure adequate pad size relative to the drill hole to guarantee a strong connection for Сборка печатной платы и надежность.

-

Припаяя маска & Шелковик: White solder mask aids visual inspection during SMT Assembly, while clear black silkscreen is crucial for Прототипирование печатной платы and repair.

Operational Principle:

A PCB does not generate function but enables it through its predefined conductive pathways. The etched copper traces replace discrete wiring, providing electrical connections between components. The insulating FR-4 substrate prevents short circuits. Нанесенные сквозными отверстиями (ПТХ) serve as vertical conduits, connecting the top and bottom PCB copper layers, thereby doubling the available routing area compared to a single-sided board and increasing design flexibility.

Характеристики производительности & Преимущества

-

Высокая надежность: The FR-4 TG150 substrate ensures stable performance in environments below its Tg, offering excellent thermal and mechanical stability for a rigid circuit board.

-

Excellent Electrical Properties: Low dielectric constant and dissipation factor support the signal integrity requirements of most digital and analog circuits.

-

High Manufacturability: The 1.6мм standard PCB толщина и Бессвинцовый HASL process are mature, ensuring high yield, cost control, and fast lead times.

-

Superior Solderability: The HASL finish offers a flat, wettable surface ideal for both through-hole soldering и SMT soldering processes.

-

Clear Identification: High-contrast white solder mask with black legend facilitates efficient печатная плата инспекция, тестирование, and rework.

-

Environmental Compliance: Lead-Free HASL finish complies with RoHS and other environmental directives.

Standard Manufacturing Process Flow

UGPCB adheres to IPC standards throughout our PCB fabrication process:

Panelization → Drilling → Electroless Copper Deposition → Dry Film Lamination & Imaging → Copper Plating → Etching → Solder Mask Application & Curing → Silkscreen Printing → Surface Finish (Бессвинцовый HASL) → Profiling/Routing → Electrical Testing (Летающий зонд) → Final Automated Optical Inspection (АОИ) → Packaging & Shipment.

Основные приложения & Варианты использования

This versatile two layer rigid PCB is widely used in industries that demand a balance of reliability and value:

-

Промышленный контроль: PLC interfaces, sensor modules, motor drives, HMI controller boards.

-

Бытовая электроника: Smart appliance controllers, audio amplifiers, питания, educational kits.

-

Телекоммуникации: Router/switch peripheral boards, RF antenna modules, network monitoring units.

-

Автомобильная электроника: Информационно -развлекательные системы, lighting control modules, body control modules (non-safety critical).

-

Power Electronics: Smart meter PCBs, UPS control boards, solar inverter circuitry.

-

Тест & Measurement: Data acquisition cards, instrument control panels, handheld tester boards.

Why Choose UGPCB for Your 2-Layer PCB Needs?

Choosing UGPCB means partnering with a reliable Производитель печатных плат committed to quality. We specialize in Прототип печатной платы and medium-volume production, implementing rigorous Electrical Testing and IPC-A-600 based inspection on every board. From simple 2 Слоиные доски to complex multi-layer designs, Мы предоставляем эксперта PCB design for manufacturing (DFM) support and a streamlined supply chain.

Contact us today for a competitive quote and swift lead time on your 1.6mm FR-4 2-Layer PCB project!

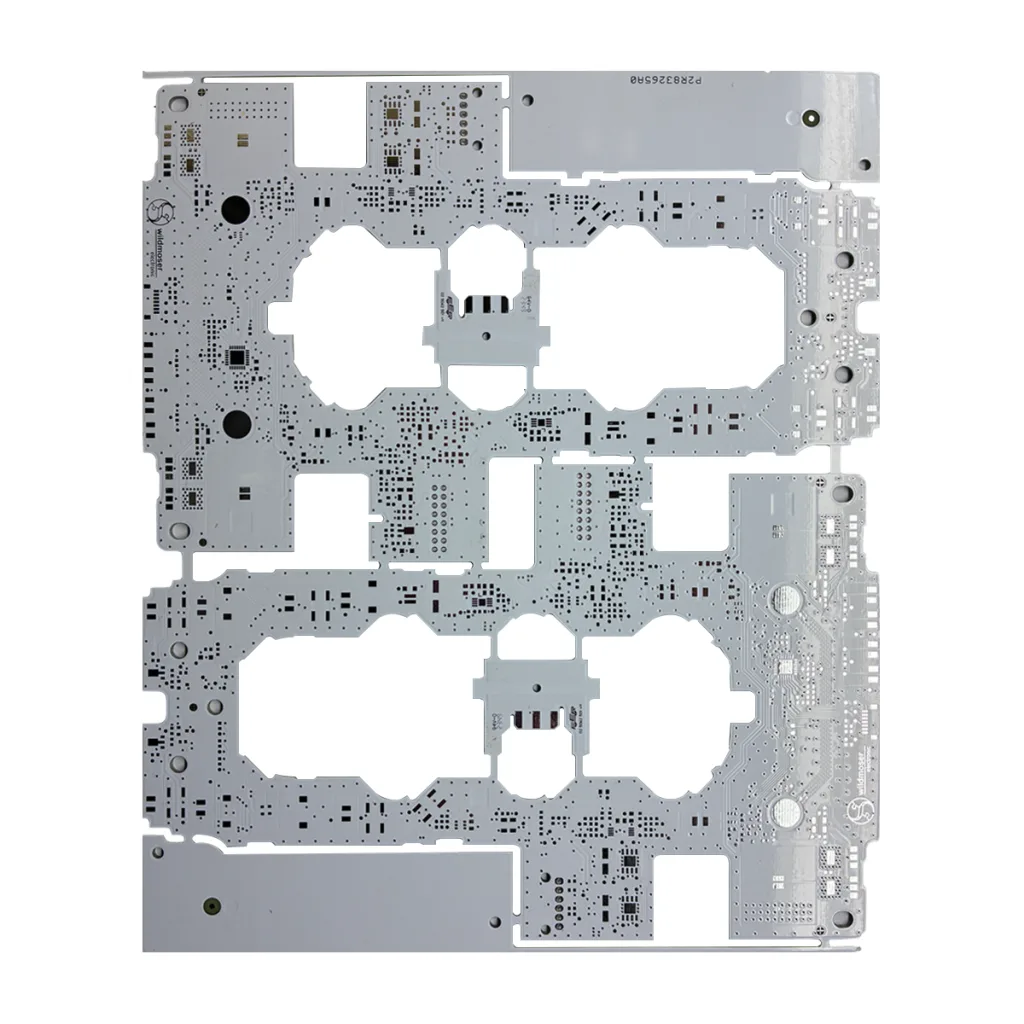

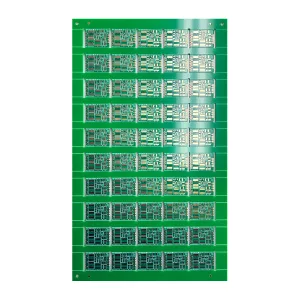

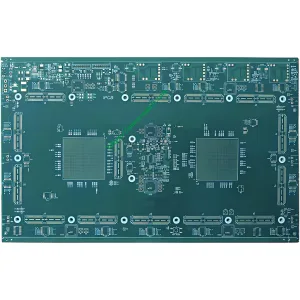

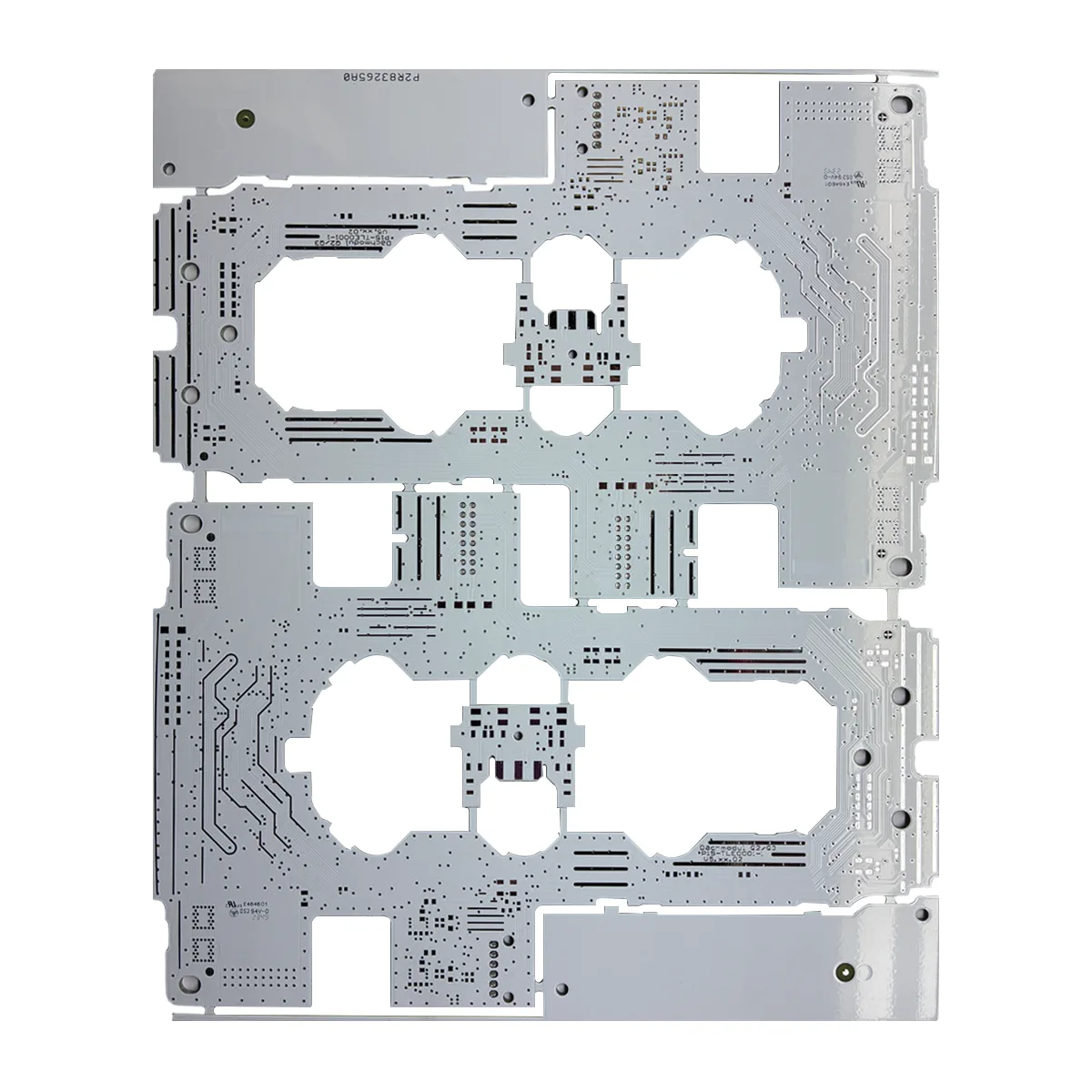

(Image Suggestion: Gallery of finished PCBs with different designs)

Alt Tag: Gallery of various 2 layer rigid PCB examples manufactured by UGPCB with white solder mask.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ