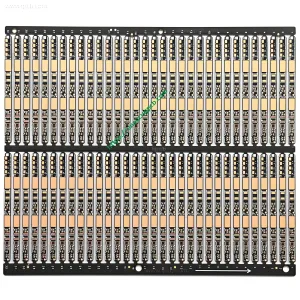

PCB -Karte zum Batterieschutz: Ein Überblick

The PCB Board for Battery Protection is a critical component designed to safeguard battery systems from overcharging, Kurzschlüsse, and other hazards. Bei UGPCB, we specialize in manufacturing high-reliability Leiterplatten that meet IPC -Standards, ensuring optimal performance for various battery management applications. This compact and efficient board integrates advanced materials and precise engineering to deliver superior protection and longevity in demanding environments.

What is a PCB Board for Battery Protection?

A PCB Board for Battery Protection is a specialized Leiterplatte (Leiterplatte) that forms the core of battery management systems (BMS). It monitors voltage, aktuell, and temperature to prevent battery damage, extending the life of devices ranging from consumer electronics to industrial equipment. With features like fine traces and immersion gold surface treatment, this PCB ensures stable signal transmission and corrosion resistance, making it a vital part of modern Leiterplatte Versammlungen.

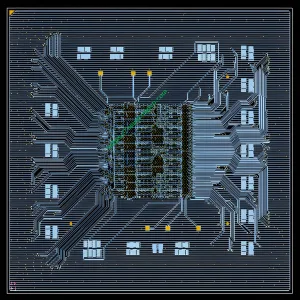

Key Design Considerations for Battery Protection PCBs

Designing a reliable battery protection PCB requires attention to detail to meet safety and performance standards. Key parameters include:

-

Trace and Spacing: Minimum trace width of 6mil (0.15mm) and spacing of 6mil (0.15mm) for high-density layouts, reducing the risk of short circuits.

-

Schichtzahl: 2 layers provide a balanced structure for simple to moderate complexity circuits, ideal for efficient PCBA integration.

-

Oberflächenbehandlung: Immersion gold offers excellent solderability and durability, crucial for long-term operation in battery protection systems.

-

Thickness and Material: A finished thickness of 0.6mm with FR4 material ensures mechanical strength and thermal stability, supporting robust PCB performance in varied conditions.

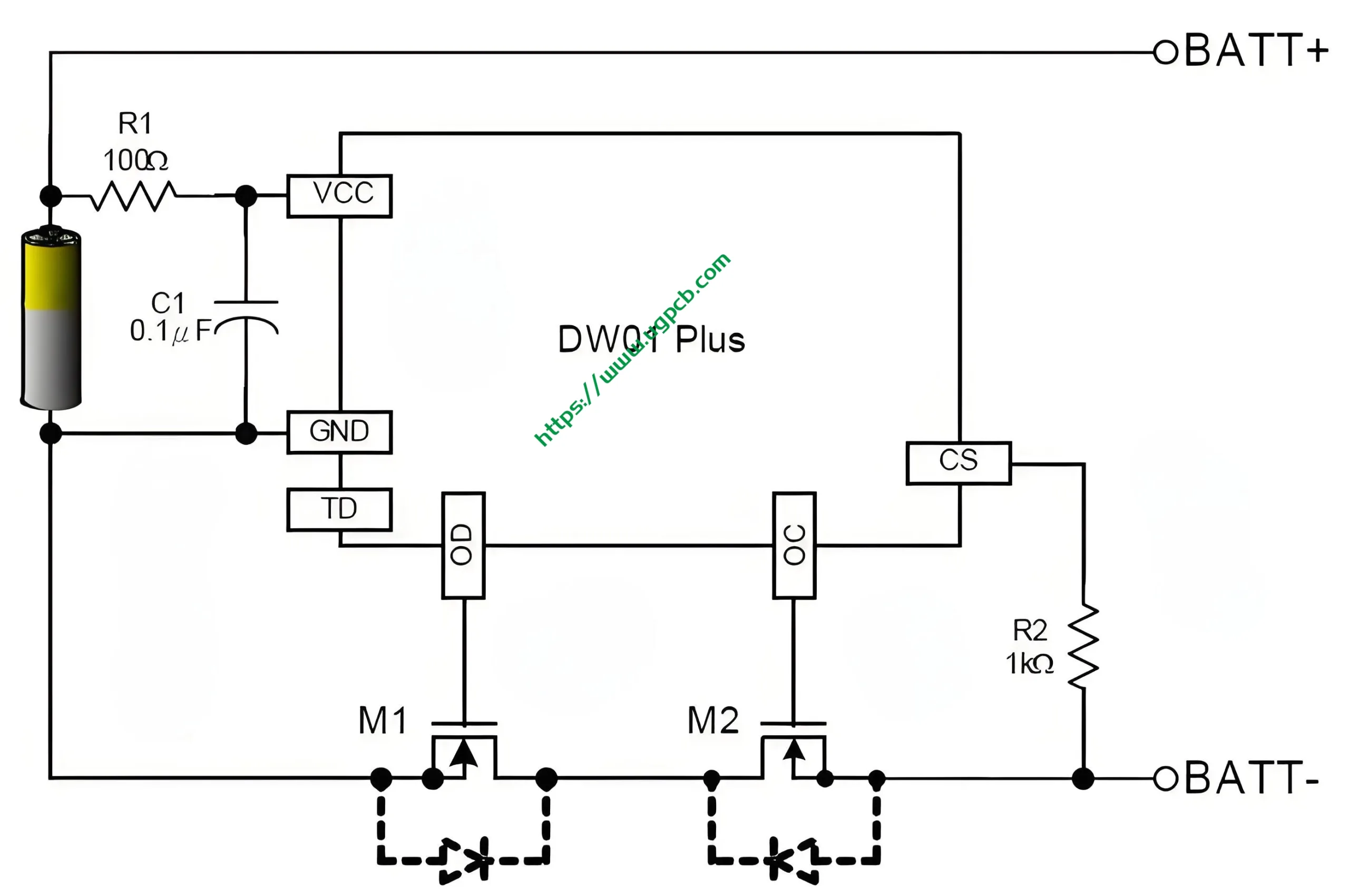

How Does a Battery Protection PCB Work?

The PCB Board for Battery Protection operates by integrating sensors and control ICs onto the board to continuously monitor battery parameters. If anomalies like overvoltage or overheating are detected, the PCB triggers protective mechanisms—such as disconnecting the circuit—to prevent damage. This process relies on the board’s precise circuitry, including 1OZ copper layers for efficient current handling, ensuring safe and reliable battery operation in PCBA setups.

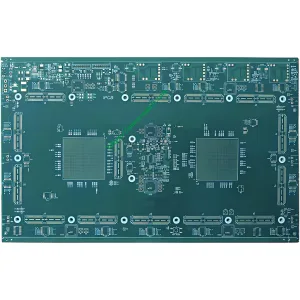

Applications and Uses of Battery Protection PCBs

These PCBs are essential in a wide range of applications, einschließlich:

-

Unterhaltungselektronik (z.B., Smartphones, Laptops, and power banks).

-

Electric vehicles and energy storage systems.

-

Industrial equipment and renewable energy solutions.

By providing critical safety functions, battery protection PCBs help maintain device integrity and are a key Komponente in PCBA services for battery-dependent industries.

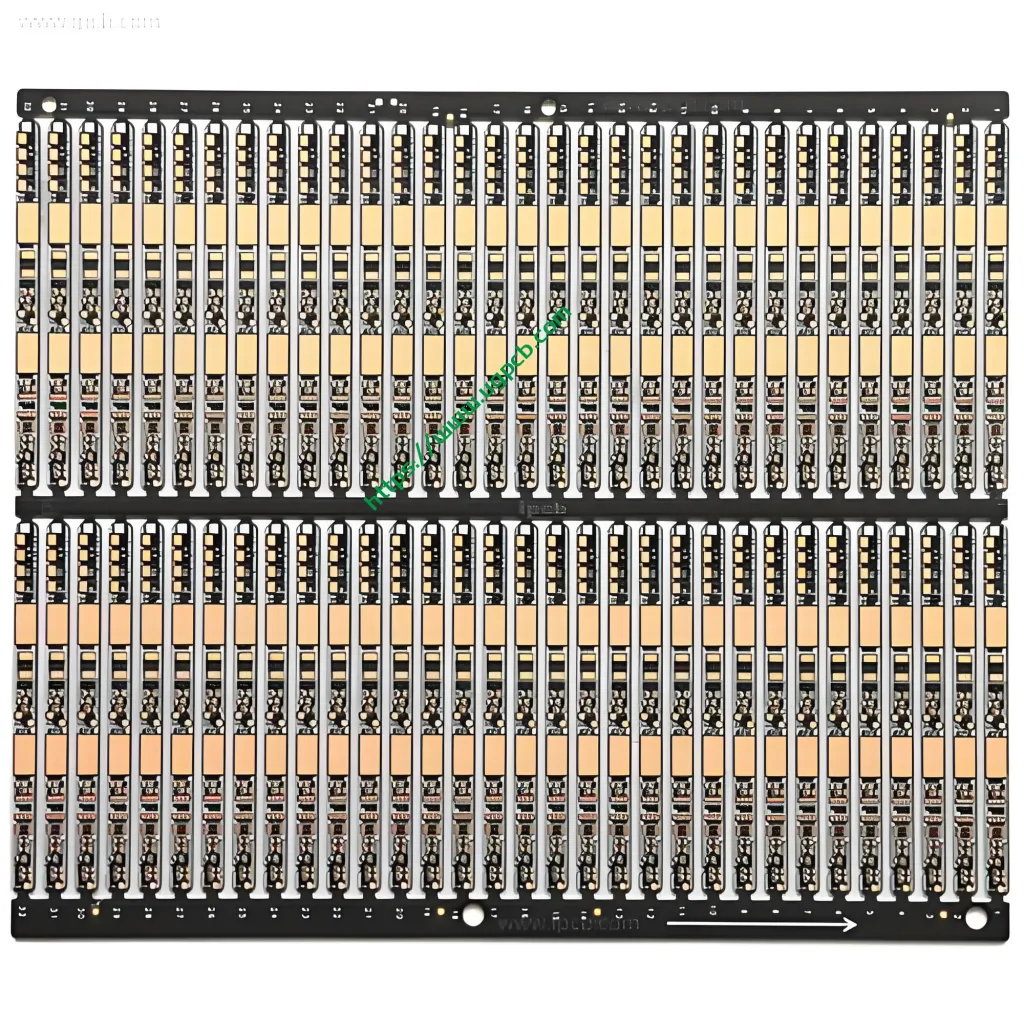

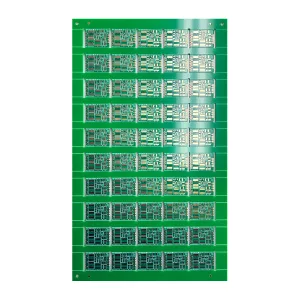

Classification of Battery Protection PCBs

Battery protection PCBs can be categorized based on factors like layer count, Material, and application-specific requirements. Gemeinsame Klassifizierungen umfassen:

-

By Layers: Einzelschicht, doppelschichtig (like this 2-layer model), or multi-layer PCBs for complex systems.

-

Durch Anwendung: Standard vs. high-performance variants, tailored for different battery types (z.B., Li-ion or lead-acid).

This diversity allows for customized PCB solutions that align with specific PCBA and battery management needs.

Materials Used in Battery Protection PCBs

UGPCB uses high-quality FR4 material for this PCB, known for its excellent electrical insulation, flame resistance, and mechanical durability. Combined with 1OZ copper thickness and immersion gold surface treatment, the material selection ensures compliance with IPC standards, providing a reliable foundation for PCB and PCBA applications in harsh environments.

Leistung und Spezifikationen

The PCB Board for Battery Protection delivers exceptional performance with the following specifications:

-

Fertige Dicke: 0.6mm for a slim profile.

-

Kupferdicke: 1OZ for optimal conductivity.

-

Farboptionen: Black or white to suit design preferences.

-

Key Characteristic: Compact size (“the individual is very small”), enabling integration into space-constrained devices.

These features make it a top choice for high-efficiency PCB -Designs and PCBA assemblies, emphasizing reliability and precision.

Structure and Composition of the PCB

This PCB features a 2-layer structure with a core of FR4 substrate, copper conductive layers, and a protective solder mask. The immersion gold surface finish enhances connectivity and resistance to environmental factors. Its layered design supports complex circuitry while maintaining a low profile of 0.6mm, ideal for streamlined PCBA integration in battery protection systems.

Schlüsselmerkmale und Vorteile

-

Hohe Zuverlässigkeit: Withstands rigorous conditions thanks to FR4 material and immersion gold treatment.

-

Kompaktes Design: Small form factor allows for easy placement in tight spaces.

-

Präzisionstechnik: 6mil traces and spaces enable high-density layouts, improving PCB performance.

-

Vielseitigkeit: Suitable for diverse applications, from consumer gadgets to industrial PCBA projects.

These benefits ensure that the PCB Board for Battery Protection meets the demands of modern electronics, boosting both safety and efficiency.

Production Process at UGPCB

Our manufacturing process strictly adheres to IPC standards to ensure quality compliance:

-

Design und Layout: Creating schematics with a focus on battery protection requirements.

-

Materialvorbereitung: Cutting FR4 substrates to size.

-

Layer Lamination and Etching: Forming circuits with precise trace widths.

-

Oberflächenbehandlung: Applying immersion gold for enhanced durability.

-

Prüfung und Inspektion: Verifying performance against specifications for reliable PCBA readiness.

This streamlined process ensures every PCB meets high standards for battery safety and functionality.

Common Use Cases and Scenarios

This PCB is widely used in scenarios such as:

-

Portable Devices: Ensuring safe operation in wearables and mobile gadgets.

-

Automobilsysteme: Protecting batteries in electric vehicles and charging stations.

-

Energy Storage: Integrating into solar power setups and backup systems.

By addressing these use cases, UGPCB’s battery protection PCBs support innovative PCBA solutions across industries, driving advancements in battery technology.

UGPCB-LOGO

UGPCB-LOGO