TG150 PCB Circuit Board Einführung: Meeting the Thermal Challenge in Modern Electronics

In high-speed communications, Automobil, Luft- und Raumfahrt, and advanced industrial controls, electronic devices face increasingly harsh operating environments. Elevated temperatures can cause standard PCB substrates (z.B., standard FR-4) to reach their glass transition, leading to softening, deformation, and critical performance loss, jeopardizing system reliability. Selecting a high-Tg Leiterplatte is essential for ensuring long-term stability in these demanding applications.

1. Produktübersicht: What is a TG150 PCB?

A TG150 PCB is a Leiterplatte fabricated using a laminate material with a glass transition temperature (Tg) of 150°C. The Tg is a crucial metric for a PCB substrate’s thermal endurance. Compared to common TG130 PCB laminates, TG150 material maintains superior physical rigidity and stable electrical properties under high temperatures. UGPCB 4-layer TG150 circuit board combines this high-performance material with an Immersionsgold (ZUSTIMMEN) Oberflächenbeschaffung and supports 0.08mm fine-line circuitry Und 0.2mm micro-drilling, making it a high-reliability mehrschichtige Leiterplatte Lösung for advanced applications.

2. Core Material and Enhanced Performance of TG150 PCB

-

Grundmaterial: A high-performance epoxy or modified FR-4 formulation, specially engineered to consistently achieve a Tg of 150°C or higher.

-

Key Performance Advantages (vs. TG130 PCBs):

-

Exceptional Thermal Stability: The increase from 130°C to 150°C Tg significantly enhances the board’s resistance to deformation at high temperatures, improving its ability to withstand high-temperature assembly processes like lead-free soldering.

-

Superior Moisture and Chemical Resistance: A denser molecular structure reduces moisture absorption in humid environments, minimizing losses in insulation resistance (Und) und Signalintegrität, while offering better resistance to chemical exposure.

-

Improved Mechanical Strength and Dimensional Stability: High Tg PCBs exhibit lower Z-axis expansion coefficients and stronger bond strength during thermal cycling, reducing risks like via cracking and delamination.

-

Stable Electrical Characteristics: Dielektrizitätskonstante (Dk) Und Dissipationsfaktor (Df) remain more stable at elevated operating temperatures, ensuring higher signal integrity for Hochfrequenz-Leiterplatten.

-

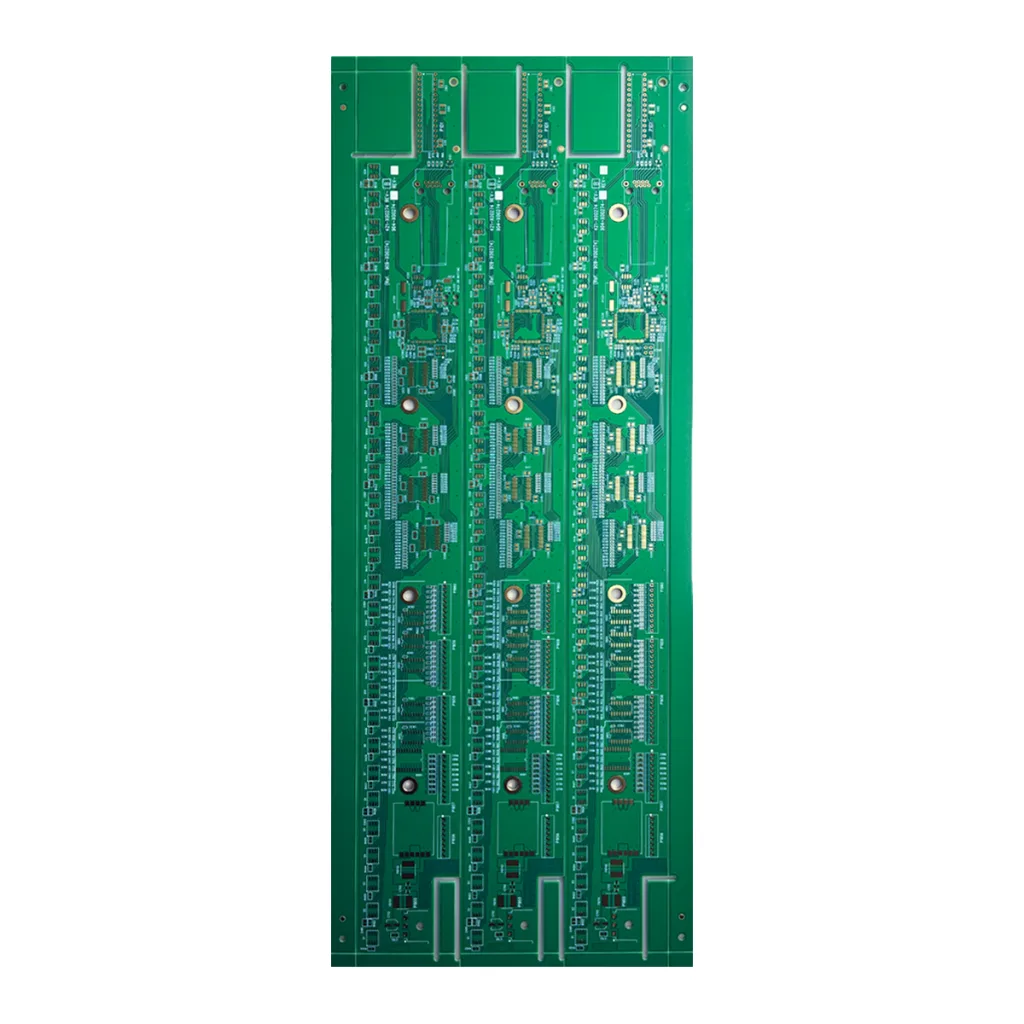

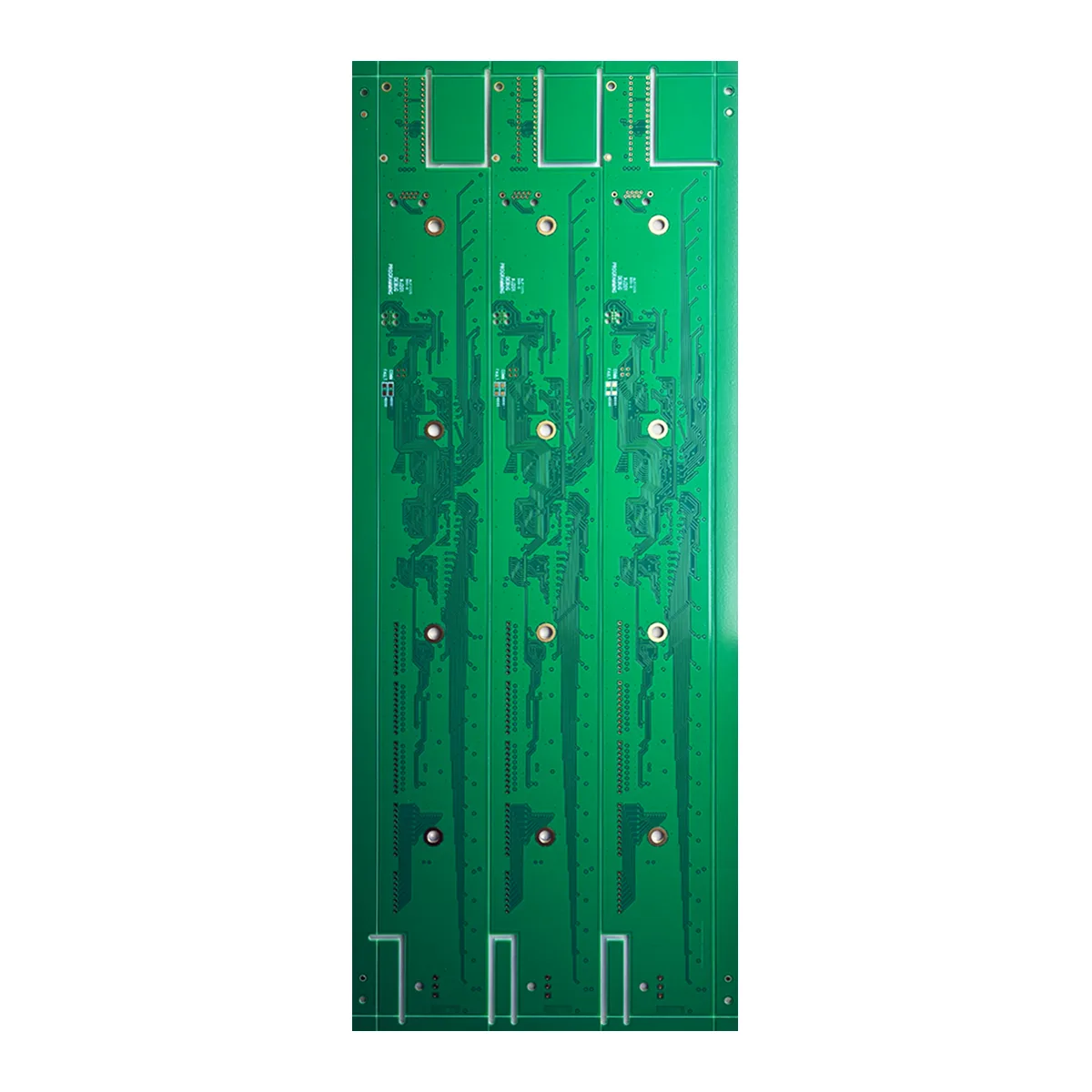

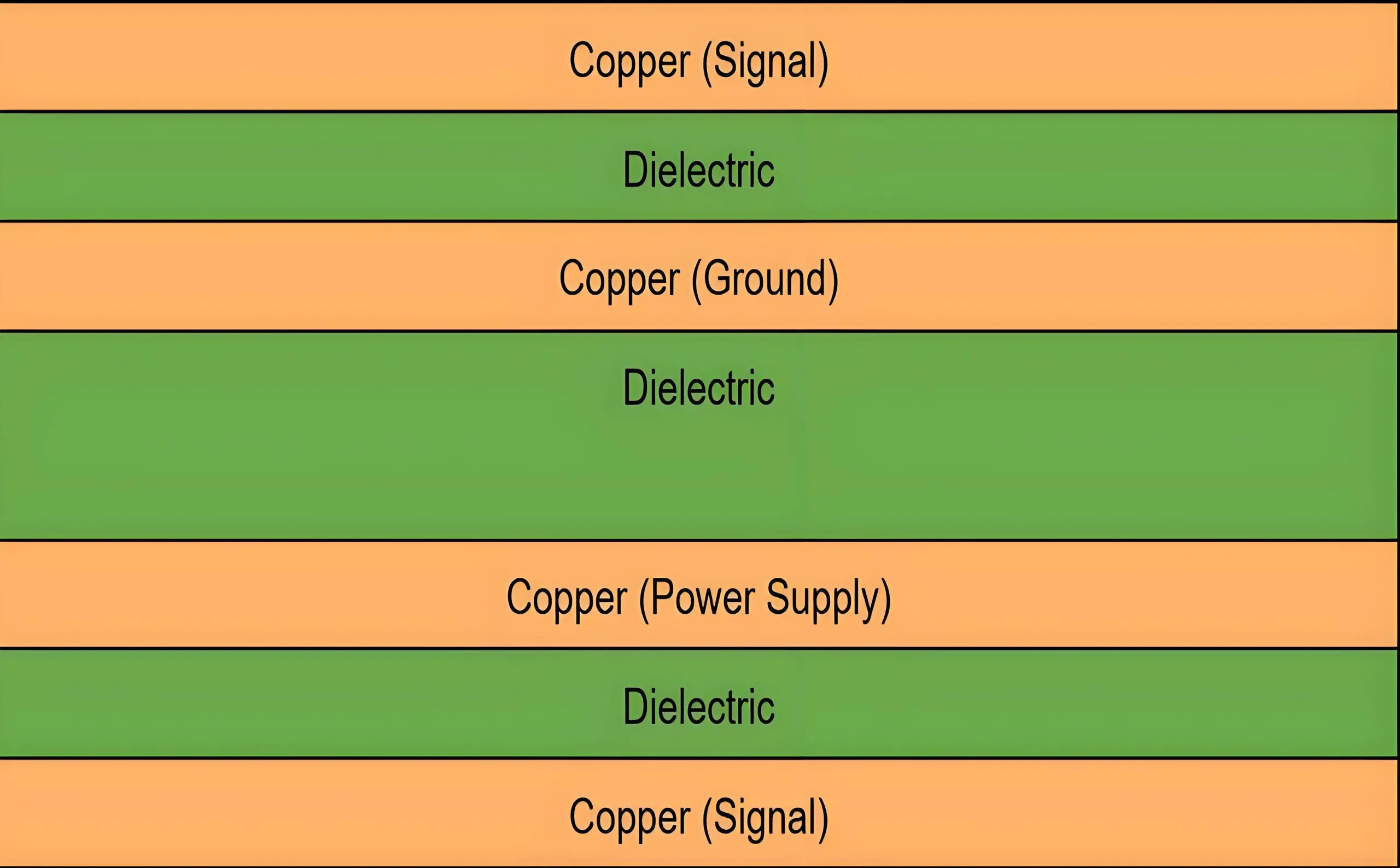

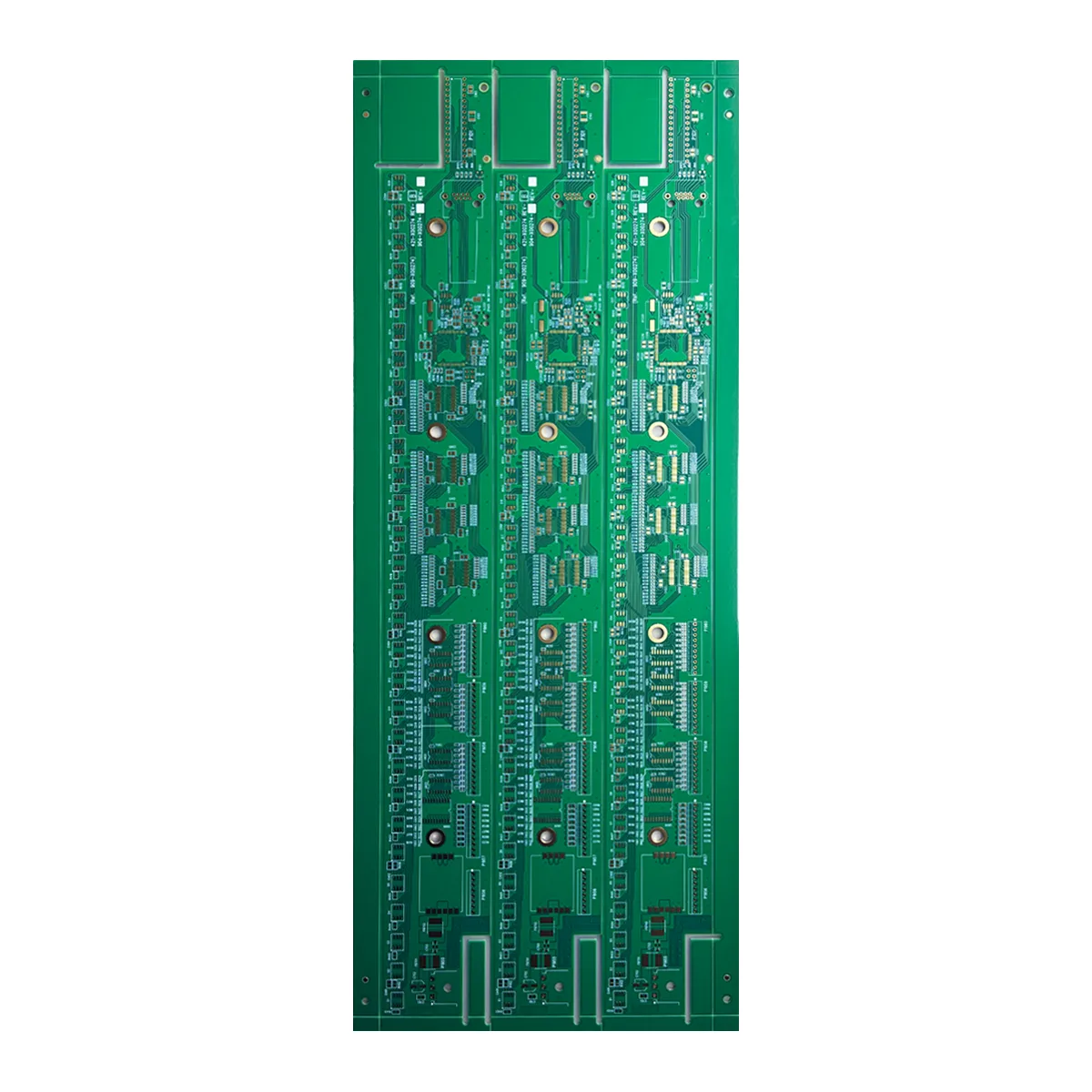

3. Structure and Design Specifications of Our TG150 PCB

PCB Stack-up

This product is a standard 4-Schicht Leiterplatte. A typical stack-up is Signalschicht – Erdungsebene – Power -Ebene – Signalschicht, providing a complete return path for high-speed signals and effective EMI control.

Key Design Capabilities & Spezifikationen

Minimum Trace Width/Space: 0.08mm / 0.1mm. This represents advanced fine-line Leiterplattenherstellung capability, essential for routing high-density ICs (z.B., BGA packages).

Drill Diameter: 0.2mm. Unterstützung micro-via drilling, facilitating higher density interconnects and saving board space.

Oberflächenbeschaffung: Immersionsgold (ZUSTIMMEN). Provides a flat surface, ausgezeichnete Lötbarkeit, and long shelf life, ideal for fine-pitch components (z.B., MFR, BGA).

4. Manufacturing Process and Quality Control

UGPCB TG150 PCB manufacturing process strictly adheres to international standards like IPC-6012 (Qualification and Performance Specification for Rigid PCBs). The process includes:

Material Preparation → Inner Layer Imaging → Etching → Lamination → Drilling (0.2mm) → Desmear & Plating → Outer Layer Imaging → Pattern Plating → Etching → Solder Mask Application → ENIG Surface Finish → Routing → Electrical Testing → Final Inspection.

At each stage, we employ advanced equipment (z.B., LDI imaging, AOI -Inspektion) and rigorous reliability testing (z.B., Wärmespannung, ionic contamination) to ensure the quality of every high-Tg circuit board.

5. Product Classification and Typical Applications

-

Technische Klassifizierung:

-

By Tg: Mid-High Tg PCB (Tg ≥ 150°C).

-

Für Schichtzahl: Mehrschichtige Leiterplatte (4-Layer Board).

-

Nach Technologie: Precision PCB (HDI-ready capability).

-

By Finish: ENIG PCB, Fine-Line PCB.

-

-

Ideal Application Scenarios:

-

Kfz -Elektronik: Engine Control Units (ABDECKUNG), Infotainmentsysteme, power management modules – requiring tolerance under-hood temperatures.

-

Telecommunications Equipment: 5G base station PAs, optical modules, network switches – where high power generates sustained heat.

-

Industriekontrollen: Servo fährt, PLCs, industrial PCs – for reliable operation in hot factory environments.

-

Power Electronics: High-power switch-mode power supplies (SMPS), inverters – where power components generate significant heat.

-

Luft- und Raumfahrt & Verteidigung: Electronic systems with extreme demands for reliability and environmental resilience.

-

6. Why Choose UGPCB for Your TG150 PCBs?

-

Zertifizierte Materialien: We use verified, traceable TG150 PCB laminates from reputable suppliers.

-

Precision Manufacturing: Our expertise in multilayer PCB fabrication Und ENIG processing ensures high yield for 0.08mm fine-line designs.

-

Guaranteed Specifications: All technical parameters (Tg 150°C, 0.2mm drills) are rigorously validated against datasheets.

-

End-to-End-Unterstützung: We provide full technical support from PCB-Design Rezension Und Impedanzkontrolle to rapid prototyping and volume production.

7. Maßnahmen ergreifen: Secure Your Design with a Robust Foundation

Don’t let thermal limitations hinder your product innovation. Choosing UGPCB’s high-reliability TG150 PCB means investing in exceptional stability, Haltbarkeit, und Leistung.

Aufruf zum Handeln

*(Image Suggestion: High-quality close-up photo of a populated TG150 PCB used in a telecom orautomotive application.)*

Alt Tag: High-density assembled 4-layer TG150 PCB with ENIG finish for automotive or telecom applications

Is your next project facing thermal reliability challenges?

Do you need a PCB that can withstand rigorous environmental stress?

Contact the UGPCB expert team today!

[Click here to Get a Free Quote for TG150 PCBs]

[Upload Your Gerber Files for a 24-Hour Design Review]

Let our expertise in high-performance Leiterplattenherstellung power your success.

UGPCB-LOGO

UGPCB-LOGO