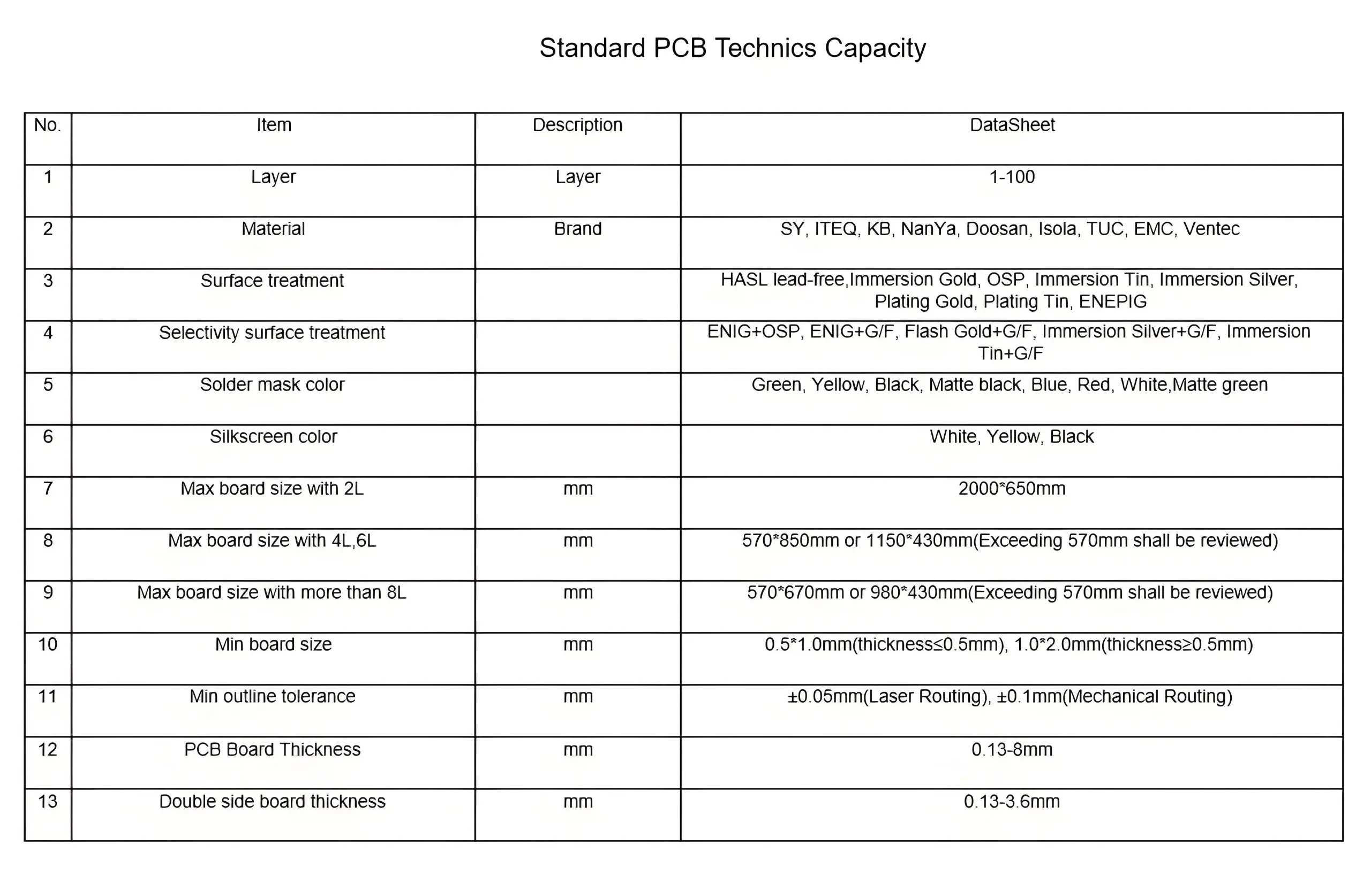

Precision Circuit Imaging & Etching Technology

UGPCB Factory demonstrates exceptional process control in circuit patterning and etching. For standard PCB production, we consistently achieve:

- Imagerie directe laser (ILD) replacing traditional photolithography masks, enabling digital file-based exposure with ±5μm alignment accuracy

- Alkaline etching process ensuring clean line edges with ±15% line width control (industry-leading tolerance)

- Expertise in handling various copper thicknesses (1oz-6oz) with minimized side-etching

High-Precision Drilling & Hole Metallization

Our drilling capabilities cover:

- Forage mécanique for 0.4mm-3.0mm boards with ±0.025mm hole size tolerance

- Forage laser down to 0.1mm microvias

- Hole metallization réalisation >20μm uniform copper plating through advanced chemical deposition and electroplating

- Special processes for 8:1 à 10:1 aspect ratio requirements

Multilayer Lamination & Interlayer Alignment

- Up to 100-layer PCB fabrication using FR-4 Grade A materials

- Precision lamination with ±15um layer-to-layer alignment

- Temperature/pressure/time-controlled processes preventing delamination

- Options for high-Tg materials, high-speed laminates, and heavy copper up to 1000μm

Masque de soudure & Surface Finish Options

- Solder mask colors: Green/Blue/Red/Black with 0.08mm minimum solder bridge

- Finitions de surface:

- HASL (Nivellement de la soudure à air chaud)

- ACCEPTER (Or par immersion au nickel autocatalytique)

- Immersion Tin/Silver

- OSP (Conservateur de soudabilité organique)

Comprehensive QC & Testing Systems

- Inspection AOI: High-resolution defect detection for line/space, coussinets, shorts/opens

- Contrôle de l'impédance: ±10% tolerance for high-speed/RF applications

- Tests électriques: Sonde volante & fixture-based continuity verification

- Reliability Testing: Choc thermique, humidity resistance, flexural testing

Process Capability & Stabilité

- Cpk >1.33 (4un) across critical processes, atteindre 1.67 (5un) in key areas

- Line width control within ±15% (vs industry 20% standard)

- Statistical process control (CPS) ensuring consistent production quality

PCBA One-Stop Services

- Assemblage SMT: 01005 component handling with ±0.03mm placement accuracy

- Emballage avancé: BGA/Micro BGA/PoP support with X-ray inspection

- DFM Support: Impedance calculation, conception empilable, manufacturability analysis

Applications de l'industrie & Contact

Serving consumer electronics, contrôles industriels, télécommunications, dispositifs médicaux, and automotive sectors with tailored PCB solutions. Visit our website for process capability reports and free DFM consultation.

LOGO UGPCB

LOGO UGPCB

WeChat

Scannez le code QR avec WeChat