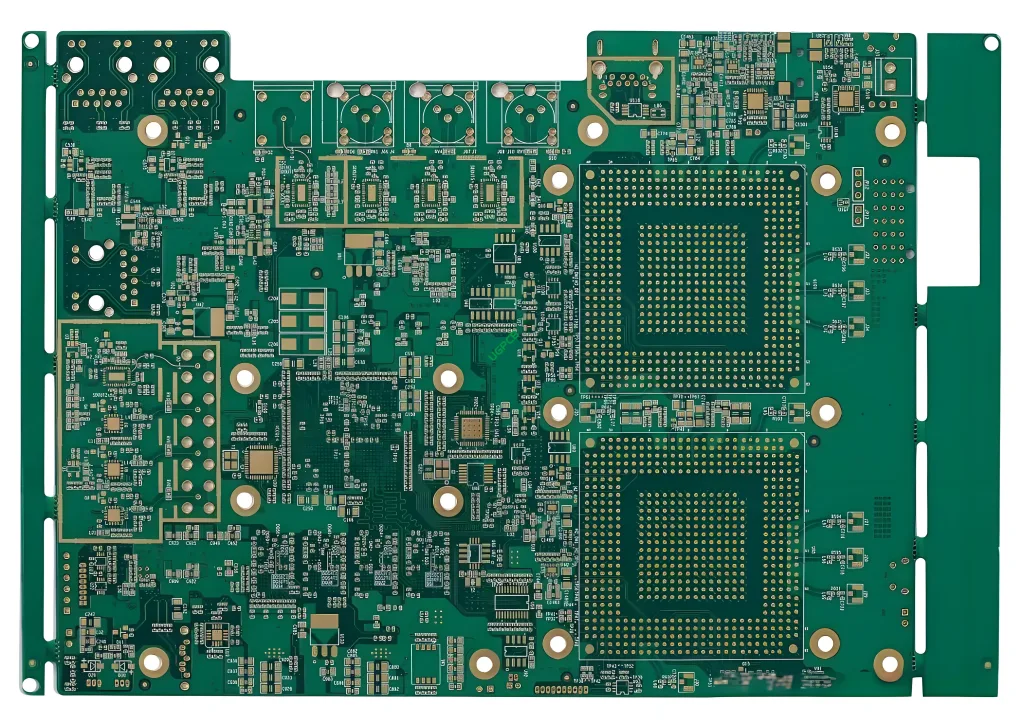

What is a BGA PCB?

A Ball Grid Array (BGA) Circuit imprimé (PCB) is a type of circuit imprimé that features a grid of solder balls on its underside, used for connecting composants électroniques to the board. This design allows for higher input/output connection density and improved electrical performance compared to traditional through-hole or surface-mount technology (CMS) PCB.

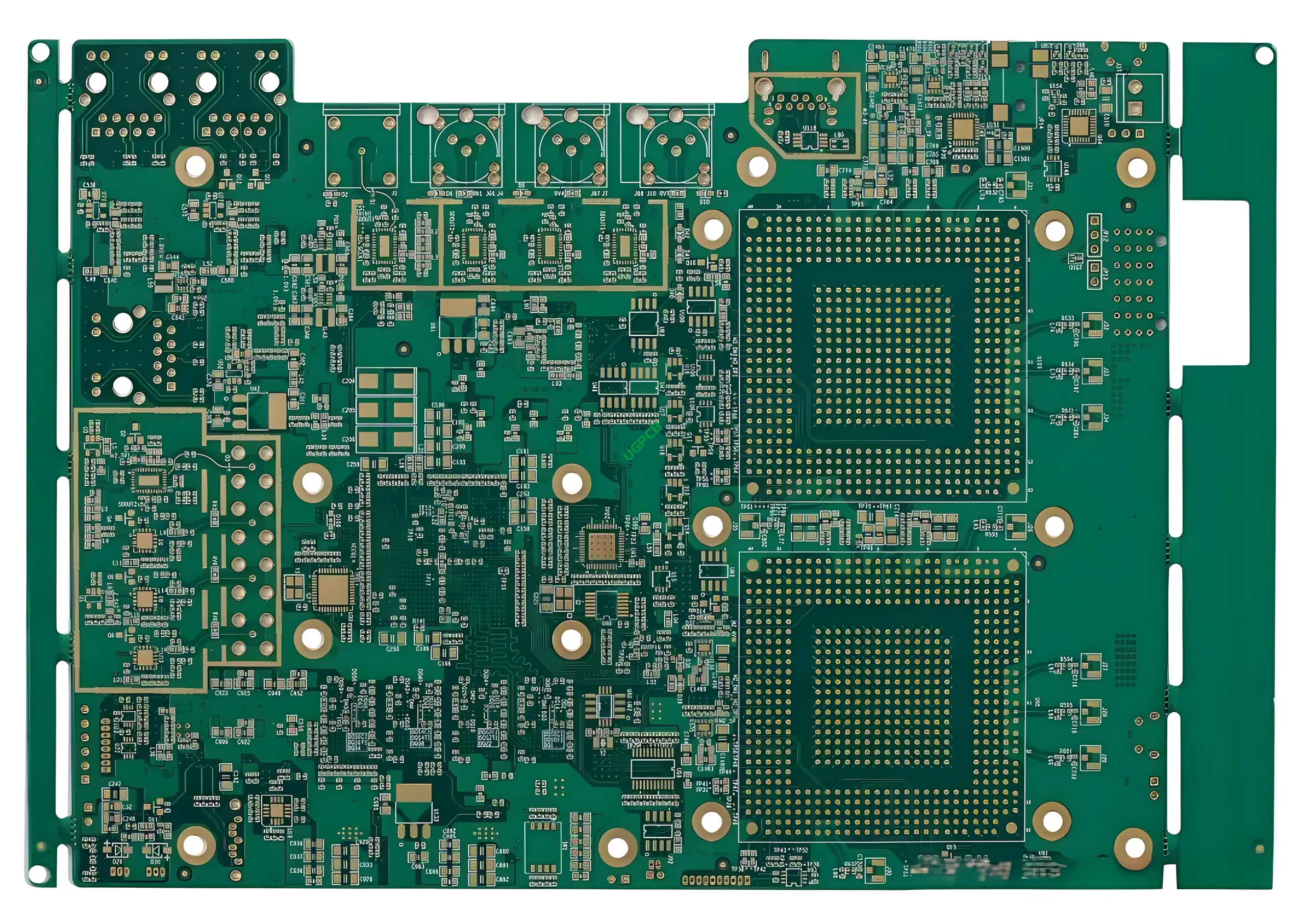

Exigences de conception

Designing a BGA PCB involves several key considerations:

- Matériel: Typically made from FR-4, a composite material known for its excellent electrical properties and affordability.

- Nombre de couches: Multilayer designs are common, providing more space for complex circuitry.

- Épaisseur du cuivre: Generally specified as 1/1OZ, balancing conductivity with cost-effectiveness.

- Traitement de surface: Often includes immersion gold to enhance solderability and protect against oxidation.

- Trace and Space: Minimum trace and space are typically set at 4mil, allowing for fine details in the circuit design.

Comment ça marche?

The BGA PCB functions by providing a platform where electronic components can be mounted and interconnected using a grid of solder balls. These balls are aligned in a pattern on the underside of the board, corresponding to contact pads on the component. When heat is applied, the solder melts and creates a strong bond, ensuring reliable electrical connections.

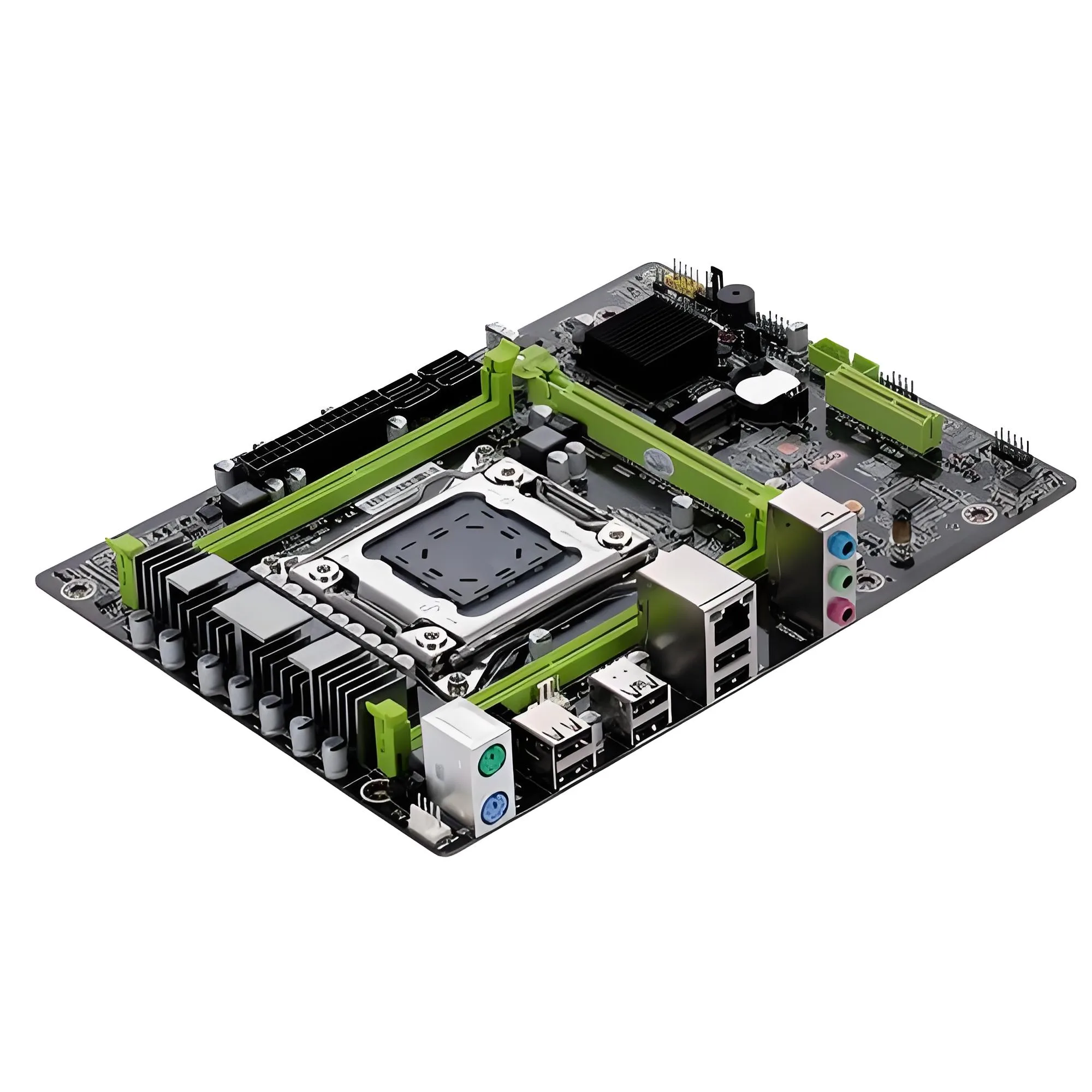

Applications

Due to their high density and reliability, BGA PCBs are widely used in various electronic products including:

- Computer motherboards

- High-performance servers

- Networking equipment

- Advanced consumer electronics like gaming consoles and smart devices

Classification

BGA PCBs can be classified based on several factors:

- Par matériau: Most commonly made from FR-4 due to its balance of cost, force, et propriétés électriques.

- Par nombre de couches: Can range from double-sided to multilayer configurations, en fonction de la complexité du circuit.

- Par traitement de surface: Options include immersion gold, hasl, or organic solderability preservatives (OSP), each offering different levels of protection and solderability.

Matériaux utilisés

La primaire matériels used in manufacturing BGA PCBs include:

- FR-4: A glass-reinforced epoxy laminate that provides excellent mechanical strength and thermal stability.

- Cuivre: Used for the conductive layers, with thickness varying based on design requirements.

- Masque de soudure: Typically green or white, il protège les traces de cuivre de l'oxydation et des courts-circuits accidentels.

- Immersion Or: A surface treatment that improves solderability and protects against corrosion.

Caractéristiques de performance

Key performance attributes of a BGA PCB include:

- Densité élevée: Allows for more components to be packed into a smaller area.

- Fiabilité: The use of solder balls reduces the risk of mechanical failure due to vibration or impact.

- Intégrité du signal: Improved due to shorter signal paths and reduced crosstalk.

Composition structurelle

Structurellement, a BGA PCB comprises:

- Couches conductrices: Made of copper, etched into the desired circuit patterns.

- Couches isolantes: Éviter les courts-circuits électriques entre les couches conductrices.

- Solder Balls: Arranged in a grid pattern on the underside of the board for component attachment.

Caractéristiques distinctives

Some notable features of a BGA PCB are:

- Fine Pitch: Allows for high-density interconnects, making it ideal for compact devices.

- Robustness: The use of solder balls provides a strong mechanical bond between the board and components.

- Versatilité: Suitable for a wide range of applications due to customizable layer counts and material choices.

Processus de production

The manufacturing process of a BGA PCB involves several steps:

- Conception et disposition: Utiliser un logiciel spécialisé pour créer le modèle de circuit.

- Préparation des matériaux: Découpe des matériaux de base sur mesure et nettoyage des surfaces.

- Laminage: Empiler et coller des couches individuelles sous chaleur et pression.

- Gravure: Enlever l'excès de cuivre pour former les chemins de circuit souhaités.

- Placage: Ajout d'une fine couche de métal aux vias et aux zones de cuivre exposées.

- Application du masque de soudure: Applying the green or white coating to protect traces.

- Traitement de surface: Applying immersion gold or other treatments for solderability.

- Inspection finale: Assurer la qualité et la fonctionnalité avant expédition.

Cas d'utilisation

Common scenarios where a BGA PCB might be employed include:

- Applications d'interconnexion haute densité dans les appareils mobiles.

- Systèmes de communication avancés nécessitant une faible perte de signal.

- Instruments médicaux portables nécessitant des performances fiables dans des environnements difficiles.

- L’électronique automobile exigeant robustesse et longévité.

En résumé, the BGA PCB represents a significant advancement in printed circuit board technology, offrant une complexité et des performances inégalées pour les applications électroniques modernes. Sa flexibilité de conception, combiné à une intégrité et une durabilité supérieures du signal, makes it an essential component in the development of next-generation electronic products and beyond

LOGO UGPCB

LOGO UGPCB