Introduction to Medical Device PCB

Le circuit imprimé (PCB) l'entreprise a étendu son influence bénéfique irrésistible en raison de la croissance continue du monde de la technologie et de son utilisation dans divers domaines. Au cours des dernières années, son impact sur le monde de l'électronique a dépassé toutes les prévisions, y compris les appareils IoT, téléphones intelligents, ordinateurs, intelligence artificielle, et plus. Maintenant, Les PCB transforment les dispositifs médicaux et comblent le fossé entre les patients et les médecins dans le secteur de la technologie médicale, enabling the development of convenient medical devices that help solve key challenges in healthcare.

The Growing Importance of PCBs in Medical Electronics

The medical electronics industry is growing rapidly and shows no signs of slowing down, highlighting the significant influence of PCBs in the medical field. The global medical electronics market is projected to reach $4.4 milliards 2022. With technological advancements, PCBs are becoming increasingly crucial in medical devices, as most modern medical gadgets require them to function properly and efficiently. PCBs are essential for operating medical equipment such as defibrillators, appareils de stimulation musculaire électrique, MRI machines, systèmes d'imagerie médicale, Tomodensitométries, et équipement à ultrasons.

Technologie des PCB médicaux et ses types

Ensuring Reliability and Cleanliness

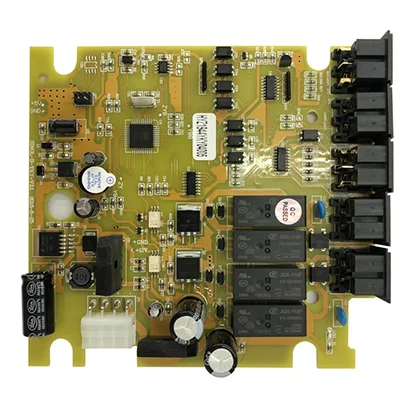

Extra care is taken in producing medical PCBs to ensure reliability, given that human life depends on the equipment they power. Medical PCBs must meet strict hygiene and cleanliness requirements, especially those used in implants. Interconnexion à haute densité (IDH) PCBs are commonly used in medical devices to achieve the necessary compactness and reliability.

Techniques utilisées dans l'assemblage de PCB médicaux

IDH / Technologie Via-in-Pad

The design of inserting vias inside copper pads, known as via-in-pad, saves space on the PCB and provides up to 50% plus d'espace pour le placement des composants. This technique is favored by PCB engineers for creating smaller, more acceptable pitch devices. Blind and buried vias also help reduce space, but via-in-pads remain the best choice for high-speed and high-dissipation PCBs.

Technologie de montage de surface

Technologie de montage de surface (CMS) is widely used in commercial device manufacturing due to its advantages in the PCB manufacturing process. SMT components are smaller, allowing more electronic devices to be packaged in a smaller space. SMT also enables automated soldering and PCB assembly, improving reliability and cost-effectiveness.

Lignes fines et espaces du PCB

Next-generation portable electronic devices rely on HDI PCB technology with tiny lines and spaces (2 mil et ci-dessous). This technology offers reduced board size, câblage amélioré, and lower manufacturing costs compared to conventional techniques.

Application of UGPCB in the Healthcare Industry

UGPCB plays a vital role in the medical industry, not only in appliances but also in monitoring, diagnostic, and therapeutic equipment. With technological advancements, UGPCB’s applications in healthcare are rapidly expanding, ouvrant de nouvelles possibilités.

Common Applications

- Équipement de numérisation: Scanners CT, Écrans à rayons X, and ultrasound scans all rely on electronic components.

- Moniteurs: Appareils de surveillance médicale tels que les moniteurs de fréquence cardiaque, glucomètres, et les tensiomètres contiennent des composants électroniques.

- Instruments médicaux: Medical research requires various instruments with PCBs, such as electron microscopes, systèmes de contrôle, and compressors.

Higher Standards and Quality Requirements

En raison de problèmes de santé, UGPCBs must meet higher standards in the medical industry. These devices must be reliable, of good quality, and often smaller in size to meet medical requirements.

Our Services

We provide Medical Equipment Turnkey PCB Assembly, medical PCB assembly, and Turnkey PCB Assembly services. UGPCB is your one-stop Turnkey PCB Assembly factory.

LOGO UGPCB

LOGO UGPCB