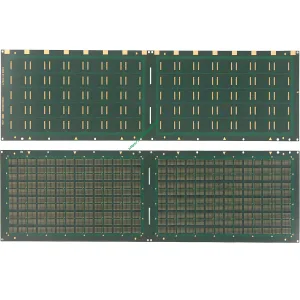

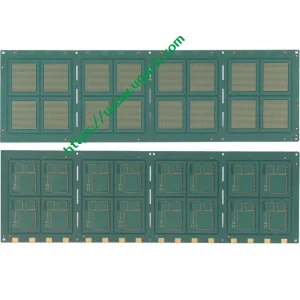

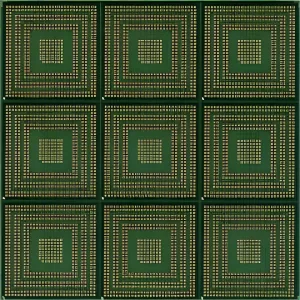

Shengyi si10u features: CTE faible, high modulus, can effectively reduce the warpage of Sensor IC Substrate, excellent heat and moisture resistance, good PCB processability, halogen-free material, tg280.

Let”s start with a brief introduction to MEMS sensors: the full name of MEMS is micro-electro-mechanical system. Micro-electro-mechanical system refers to those that can be produced in batches, combining micro-mechanisms, micro-sensors, micro-actuators, signal processing and control circuits, up to interfaces, Communication and power supply are equal to an integrated micro device or system. You can understand it as a technology that uses traditional semiconductor processes and materials to manufacture micro-machines on a chip with micron technology, and integrate it with the corresponding circuit as a whole. So it is an advanced manufacturing technology platform developed based on semiconductor manufacturing technology.

Advantages of MEMS sensors: Compared with traditional machinery, their size is smaller, the largest is no more than one centimeter, or even only a few microns, and their thickness is even smaller. It uses silicon-based materials with excellent electrical properties. The strength, hardness and Young’s modulus of silicon materials are equivalent to iron, the density is similar to aluminum, and the thermal conductivity is close to molybdenum and tungsten. Using the generation technology similar to the integrated circuit (CI), mature technology and craftsmanship in IC production can be used in large quantities and low-cost production, so that the cost performance is greatly improved compared with the traditional “mécanique” manufacturing technology.

Traditional microphones and MEMS microphones integrate seven or eight mechanical parts into a small MEMS sensor chip. So the volume is very small and the weight is very light. Because it is a chip manufacturing, it has good consistency and low power consumption, making it easier to mass produce. But the technical requirements are very high. The emergence of MEMS sensors greatly meets everyone’s requirements for small size and high performance.

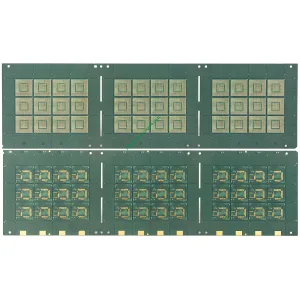

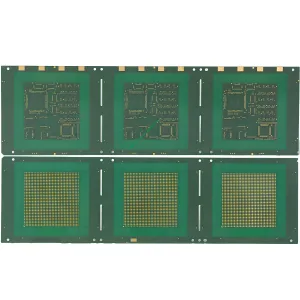

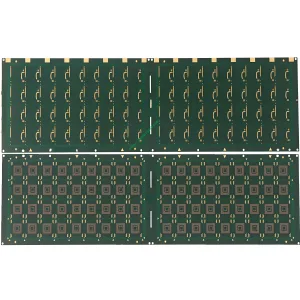

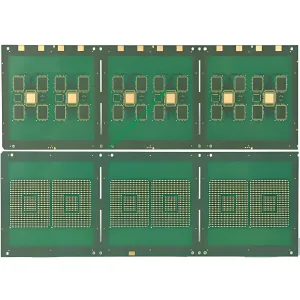

And this powerful chip is made using Sensor IC Substrate. MEMS sensors use Sensor IC Substrate as the chip substrate for a reason. Let’s first look at the application areas of MEMS, and then why it’s better to use Sensor IC Substrate. Understood.

With the development of electronic technology, the application fields of MEMS sensors are becoming more and more extensive, from the earliest industrial and military aviation applications to the ordinary consumer market. Military and aviation belong to the so-called high-value MEMS application fields, but the amount of these two fields is too small, à propos 40 million US dollars a year, and the room for growth is also limited. The value of MEMS devices in medical electronics is also good, and the average selling price of its sensors is much higher than other comparable MEMS fields. Overall, the annual operating income of the high-value MEMS industry will reach about 300 million US dollars. Cependant, the most widely used applications belong to the automotive electronics industry and consumer electronics application markets, which account for more than 60% of the MEMS sensor market. Let’s analyze these two main application areas below.

One is automotive electronics. Everyone knows that the sensors on the car are basically on the control system, mainly collecting engine data, but the operating environment of the car is very harsh, high temperature, corrosion, dust and other factors may be possible. Causes the fragile sensor to fail. A cette époque, Sensor IC Substrate is needed to ensure the normal operation of the entire sensor.

LOGO UGPCB

LOGO UGPCB