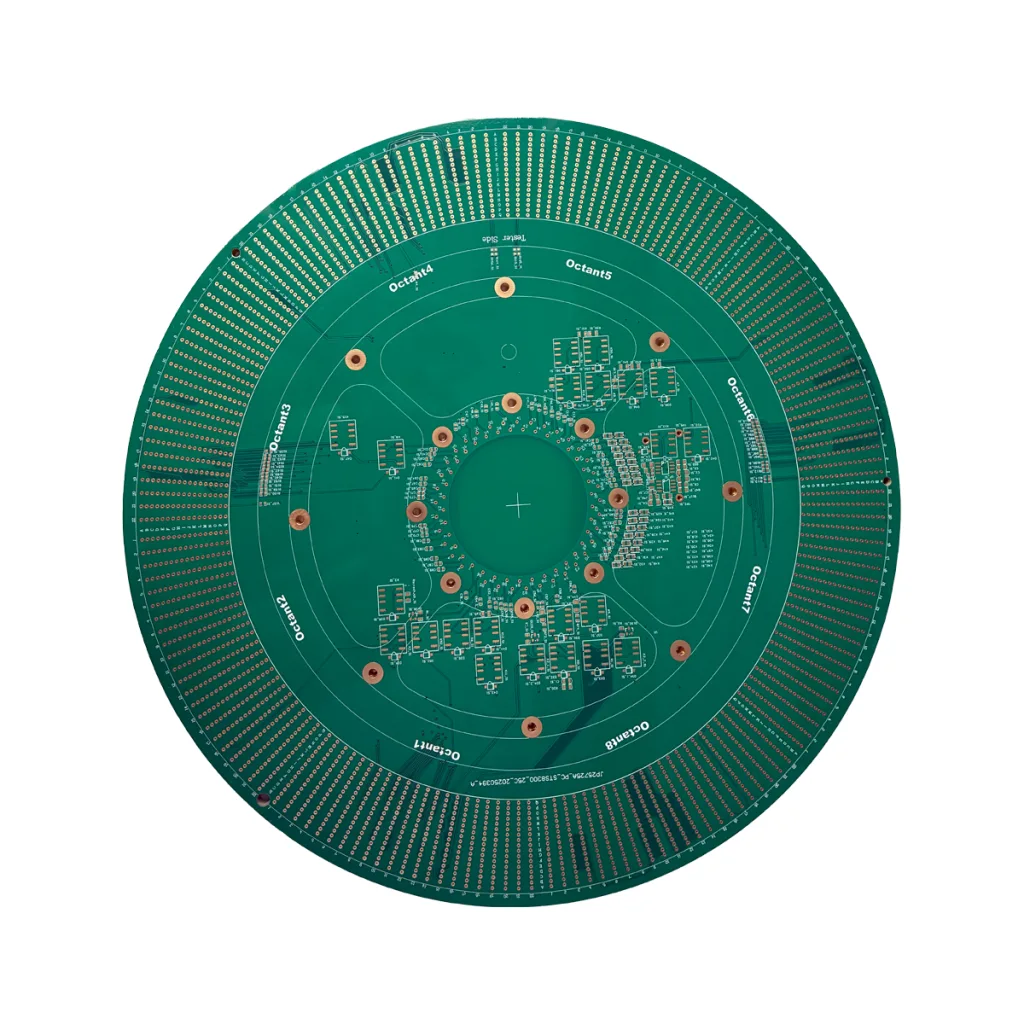

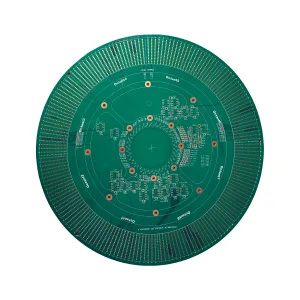

Введение в печатную плату с картой зонда UGPCB

50-х слоя UGPCB съел (Автоматизированное испытательное оборудование) Зонд карта печатная плата является точным инженерным раствором, предназначенным для высокочастотных полупроводниковых испытаний. Это обеспечивает точную передачу сигнала между тестовым оборудованием и интегрированными цепями (ICS), Обеспечение надежной производительности в критически важной среде.

Ключевые технические характеристики

-

Количество слоев: 50 слои

-

Толщина: 198 мил

-

Материал: FR4 Htg (Высокотемпературная стеклянная эпоксидная смола)

-

Минимальный размер отверстия: 5 мил

-

BGA -интервал: 0.35мм

- Толщина меди:2/2унция

-

Соотношение сторон: 40:1

-

Расстояние для тренировки: 3 мил

-

Пофв (Нанесенный наполненным через): Да

-

Поверхностная отделка: Энэг (Электролетное никелевое электролетное золото)

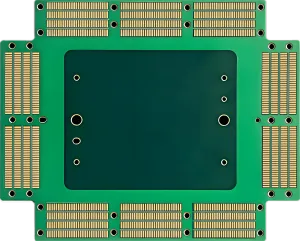

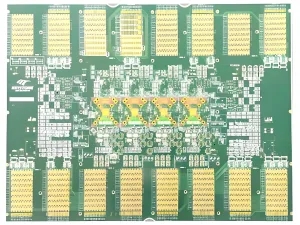

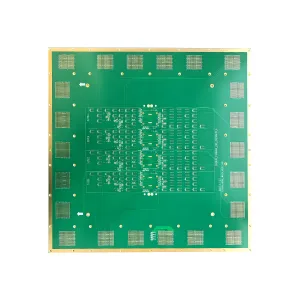

Дизайн и структурные инновации

Критические особенности дизайна

-

Взаимодействие высокой плотности: 50-слойная архитектура поддерживает ультралепую маршрутизацию для компонентов BGA с высоте 0,35 мм, необходимо для современного тестирования IC.

-

Продвинутый материал: FR4 HTG обеспечивает тепловую стабильность (TG ≥ 180 ° C), Предотвращение деформации во время мощных циклов тестирования.

-

Точное бурение: А 40:1 Соотношение сторон и 5 MIL Microvias включает надежные пути сигнала в плотно расположенных макетах.

-

Технология POFV: Заполненные и покрытые ваги. Увеличение механической прочности и термического рассеяния, критическая для длительных операций тестирования.

Структурные преимущества

-

Ультра-короткое расстояние в течение скорости: 3 МИЛ -интервал сводит к минимуму потери сигнала и перекрестные помехи.

-

Eneg Surface Finish: Обеспечивает исключительную сопротивление окисления и стабильные контактные поверхности для игл зонда.

Производительность и функциональные приложения

Операционные принципы

ПКБ маршрутирует электрические сигналы между тестовыми зондами и IC с минимальной задержкой. Подложка FR4 HTG поддерживает диэлектрическую консистенцию при термическом напряжении, В то время как POFV обеспечивает непрерывную связь в средах высокой вибрации.

Ключевые показатели производительности

-

Тепловая выносливость: Стабильные характеристики при температуре до 180 ° C.

-

Целостность сигнала: Контролируемый импеданс (± 8%) и низкая потеря вставки (<0.5дБ).

-

Механическая долговечность: Сопротивляется расслаиванию во время 10,000+ Циклы испытаний.

Основные варианты использования

-

Полупроводниковое тестирование: Проверяет логические чипы, модули памяти, и процессоры в системах ATE.

-

Аэрокосмическая электроника: Используются в тестирующих установках авионики, требующих ультра-надежных ПХБ.

-

5G и IoT -устройства производство: Обеспечивает точность сигнала при высокочастотном тесте радиочастотных компонентов.

-

Проверка автомобильной IC: Развернутые в рабочих процессах тестирования ADA и ECU.

Производственный процесс и обеспечение качества

Производственный рабочий процесс

-

Материальная резка: FR4 Laminates HTG точно вырезаны для необходимых измерений.

-

Лазерное сверление: Достигает 5 MIL отверстия с 40:1 Соотношение сторон с использованием co₂ -лазеров.

-

Покрытие и наполнение: Технология POFV усиливает VIAS с медным покрытием.

-

Выравнивание слоя: 50-Стехки слоя связаны под высоким давлением и температурой.

-

Обработка поверхности: Покрытие ENEG применяется для коррозионной устойчивости.

-

Строгое тестирование: Включает проверки непрерывности электричества, Тестирование импеданса, и проверка термического велосипеда.

Стандарты качества

-

IPC-6012 Класс 3 Согласие: Гарантирует надежность для суровых промышленных применений.

-

100% Автоматическая оптическая проверка (АОИ): Обнаружает микро-дефекты в макетах высокой плотности.

Резюме конкурентных преимуществ

-

Ультра-высокая плотность: Поддерживает миниатюрные тестирование IC с расстоянием между BGA 0,35 мм.

-

Тепловая устойчивость: FR4 HTG обеспечивает стабильность в экстремальных условиях.

-

Ведущая отраслевая точность: 5 Мил Микровия и 3 Mil Drill-To-Copper-интервал.

-

Широкая совместимость: Совместим с крупными платформами ATE, такими как Teradyne и Advantest.

Эта печатная плата сочетает в себе передовую инженерию, строгие элементы управления качеством, и специализированные материалы для удовлетворения требований полупроводникового тестирования следующего поколения.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ