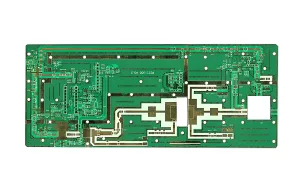

Professional 8-Layer Rogers 4350B High-Frequency PCB for Demanding RF & Microwave Applications

In the rapidly advancing fields of wireless communications, аэрокосмический, and high-end test instrumentation, Стандартные печатные платы fall short of meeting extreme demands for signal integrity, low loss, and thermal stability. UGPCB leverages deep technical expertise to present this 8-Layer High-Frequency PCB built on Rogers 4350B laminate. Engineered to address core challenges in RF applications, it is more than an interconnect—it’s a critical foundation ensuring stable performance and signal purity in advanced electronic systems.

Обзор продукта & Определение

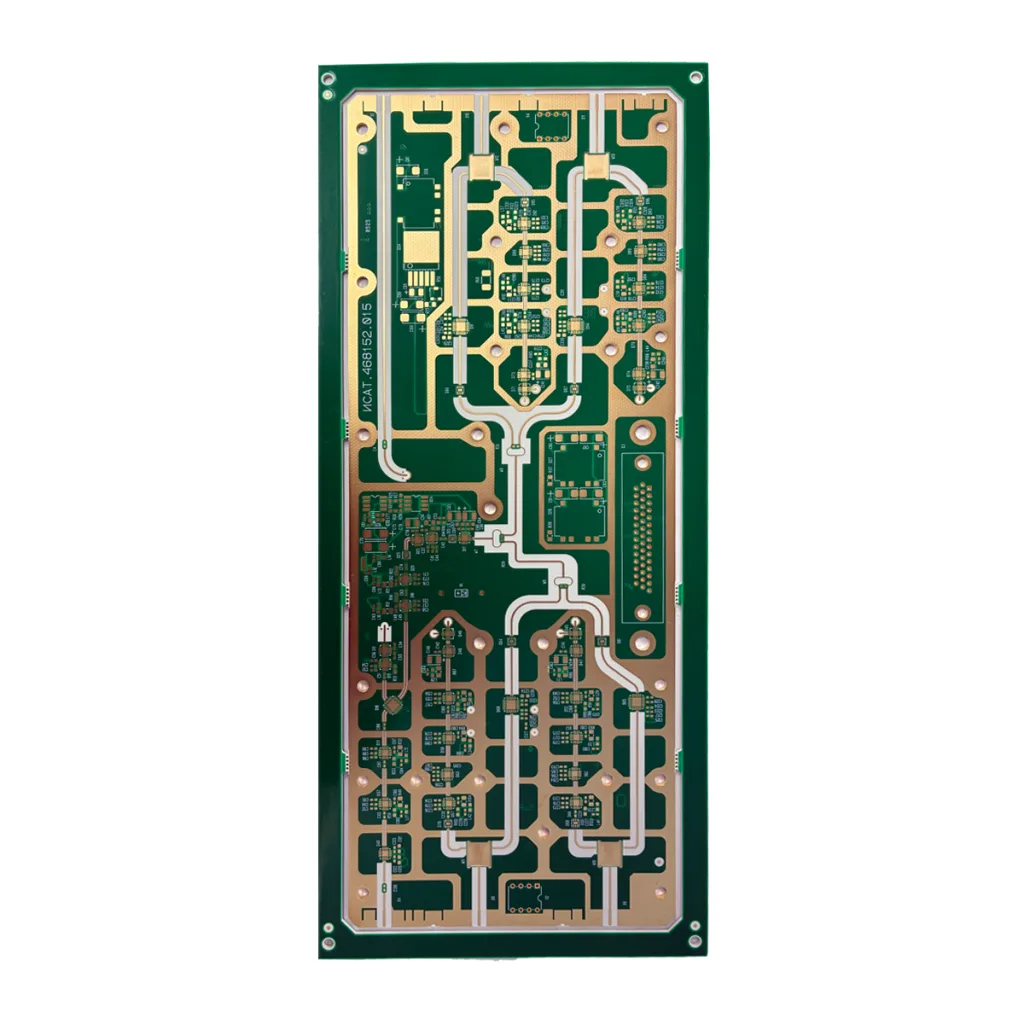

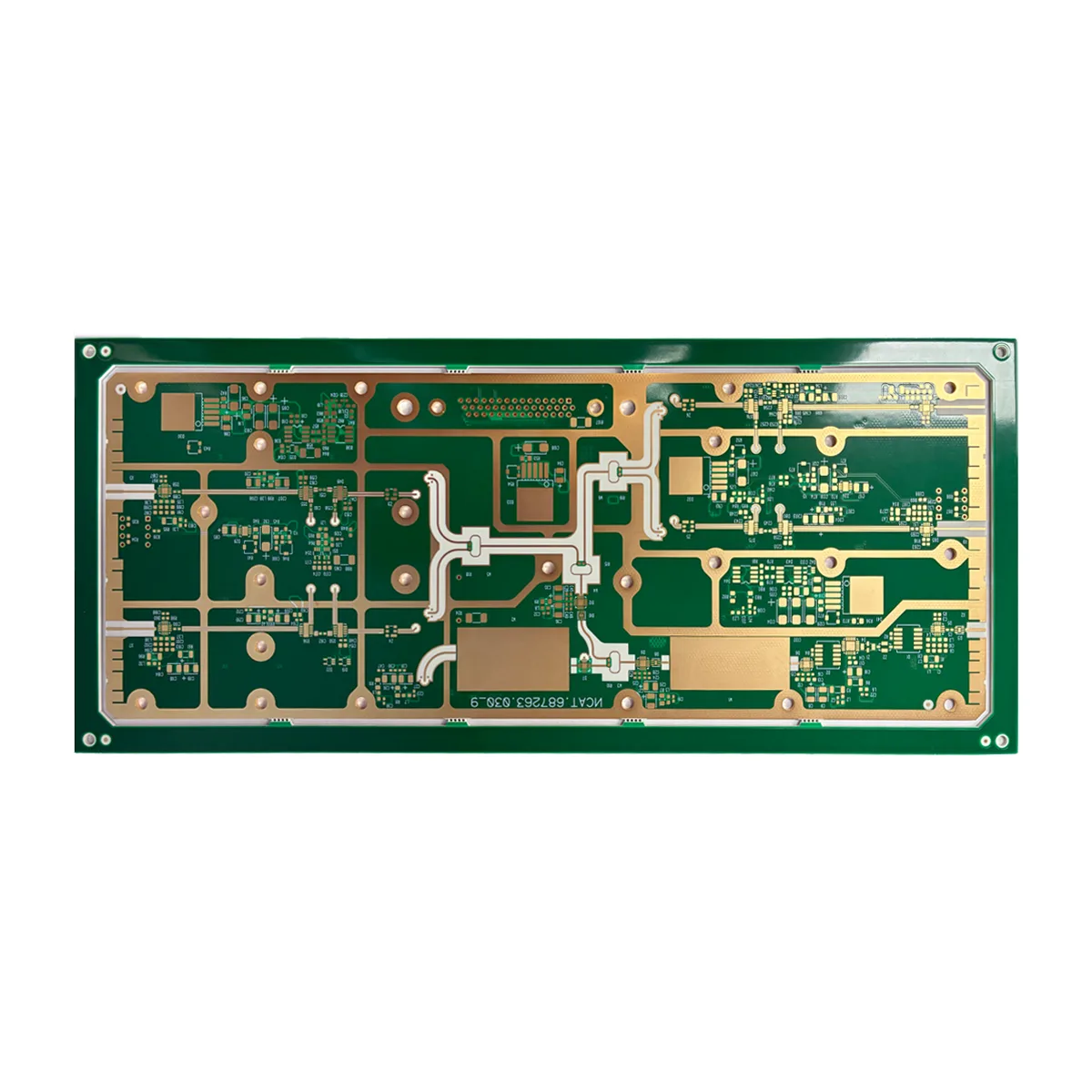

This product is an 8-layer rigid high-frequency Printed Circuit Board (печатная плата), utilizing the industry-recognized premium RF material—Роджерс 4350b. Through precision multilayer lamination and specialized processing, it achieves high-density integration of complex RF circuits within a 1.65mm board thickness, delivering superior electrical performance control. It is specifically designed for applications requiring low loss, стабильная диэлектрическая проницаемость, и отличное тепловое управление.

Detailed Specifications & Соображения дизайна

A high-quality печатная плата starts with precise control over every detail. Below are the core specifications and their design significance:

| Parameter Category | Спецификация | Design Rationale & Implication |

|---|---|---|

| Basic Structure | Слои: 8 Слои | Provides ample routing space, supports separate power, ground, and signal planes—essential for Взаимодействие высокой плотности (ИЧР) и Электромагнитные помехи (Эми) suppression. |

| Толщина доски: 1.65мм | A balanced thickness ensuring mechanical robustness and heat dissipation while accommodating spatial constraints in assemblies. | |

| Основной материал | Ламинат: Роджерс 4350b | The cornerstone of high-frequency дизайн печатной платы. Its low dissipation factor (Дф) and stable dielectric constant (Дк) with minimal variation over frequency/temperature are critical for RF/microwave circuit целостность сигнала. |

| Conductivity | Медный вес: Inner 1/1 унция, Outer 1/1 унция | Balanced copper weight ensures consistent current-carrying capacity and impedance control accuracy. 1 oz outer copper aids in heat dissipation. |

| Поверхностная отделка | СОГЛАШАТЬСЯ (Химическое никель, иммерсионное золото), 2м” | Provides a flat, highly solderable surface with excellent oxidation resistance, ensuring long-term reliability for RF connectors and BGA assemblies. |

| Physical Dimensions | 280mm x 120mm | Suited for medium-sized RF modules or subsystems, balancing integration density and mechanical strength. |

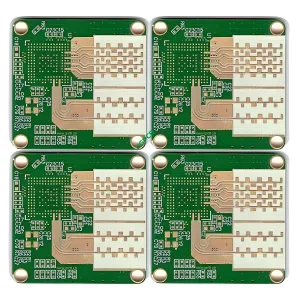

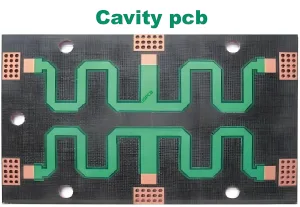

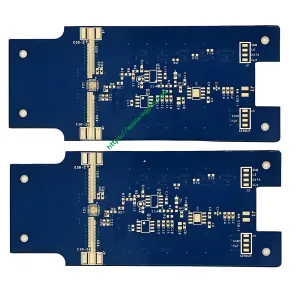

| Специальные процессы | Depth-Controlled Milling (Step-down) + Слепые исчезновения | Key for enhanced spatial efficiency and performance. Step-down milling allows varied board heights; blind vias enable high-density interconnect from surface to inner layers, reducing signal crosstalk—a hallmark of advanced RF PCBs. |

Alt tag for suggested technical diagram: Cross-section diagram of 8-layer PCB stackup showing blind vias and step-down milling.

Как это работает & Основные приложения

Принцип работы:

На высоких частотах (MHz to GHz range), electrical signal transmission behaves more like electromagnetic wave propagation. This PCB leverages the stable dielectric properties of Rogers 4350B to provide a “smooth highway” for these waves, minimizing energy loss (вносимая потеря) and waveform distortion during transmission. Its precise 8-слой стек и blind via design ensure controlled characteristic impedance (например, 50Ω or 75Ω) for transmission lines while mitigating interlayer signal reflection and crosstalk.

Key Applications:

-

Wireless Infrastructure: 5G/6G base station antennas, усилители мощности (PAs), фильтры, LNAs.

-

Satellite Comms & Аэрокосмическая промышленность: Satellite transceiver modules, радиолокационные системы, RF front-ends.

-

High-End Test & Measurement: Core boards for network analyzers, spectrum analyzers, signal generators.

-

Автомобильная электроника: Millimeter-wave radar boards for ADAS.

-

Медицинское оборудование: RF control modules in high-precision imaging systems (например, МРИ).

Scientific Classification

Per industry and IPC standards, this product is classified as a Высокочастотный, Multilayer Rigid Printed Circuit Board. More specifically, это 8-Layer Metal Core PCB with Blind Vias, fabricated on ceramic-filled hydrocarbon/glass weave reinforced laminate (Rogers 4350B series).

Строительство & Key Performance Features

Structural Analysis:

This PCB employs a classic symmetrical stack-up, comprising multiple signal layers with dedicated power and ground planes. Слепые исчезновения connect the surface to adjacent inner layers, пока through-holes provide interconnection through the entire board. Depth-controlled milling creates mechanical recesses for shield can installation or special assembly requirements.

Outstanding Performance Features:

-

Ultra-Low Signal Loss: The low dissipation factor of Роджерс 4350b at GHz frequencies ensures high-efficiency signal transmission.

-

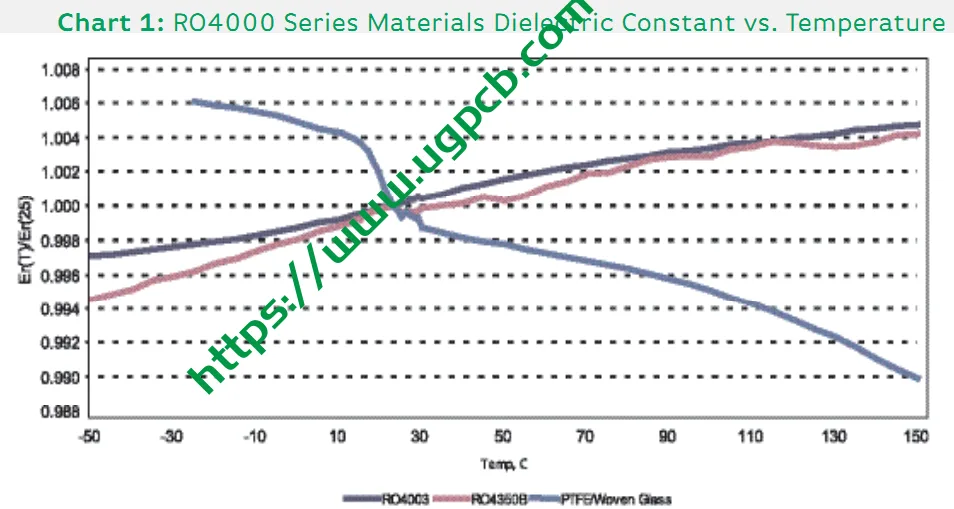

Exceptional Electrical Stability: Excellent thermal coefficient of dielectric constant (TCDk) guarantees consistent performance across a wide temperature range.

-

Превосходное управление температурным режимом: Низкий коэффициент термического расширения (КТР) and high thermal conductivity enhance reliability in high-power RF circuits.

-

High-Precision Impedance Control: Achievable tolerance of ±5% or better, thanks to material stability and UGPCB’s advanced process control.

-

High-Reliability Interconnects: Robust 2μ” ENIG finish and precision blind via technology ensure durable connections in harsh environments.

-

Повышенная гибкость дизайна: The combination of 8 слои, слепые переходы, and step milling supports highly complex and compact RF system design.

Core Manufacturing Process Flow

-

Material Prep & Inner Layer Fabrication: Rogers 4350B clad laminates are sheared, просверлил (for blind vias), plated, patterned, and etched to form inner layer circuits.

-

Layup & Ламинирование: Etched inner layer cores and prepreg sheets are aligned in the designed stack-up and bonded under high temperature and pressure.

-

Mechanical Drilling & Покрытие: Through-holes are drilled, followed by electroless and electrolytic copper plating to metallize all holes (PTH and blind vias).

-

Outer Layer Imaging & Покрытие: Outer layer circuit pattern is applied, followed by pattern plating to build up trace and hole copper thickness.

-

Поверхностная отделка: Химическое никель, иммерсионное золото (СОГЛАШАТЬСЯ) process applied to form a 2-microinch nickel-gold protective layer on pads and hole walls.

-

CNC Routing & Step Milling: The board outline is routed, и depth-controlled milling creates step-down areas as per design.

-

Electrical Test & Инспекция: 100% electrical test (flying probe or fixture) for continuity and isolation, followed by final QA inspection (including impedance coupon testing).

Typical Use Case Scenarios

-

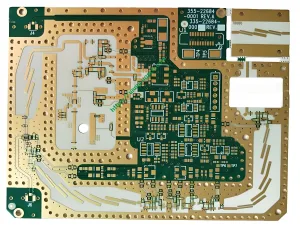

Scenario 1: 5G Massive MIMO Antenna Array Board

In such array boards, densely packed RF channels require minimal mutual interference. This PCB’s stable Dk and blind via design ensure channel isolation and phase coherence, while its superior thermal performance supports prolonged stable operation of PA chips.

Alt tag: 8-layer Rogers 4350B PCB assembly for a 5G Massive MIMO antenna unit. -

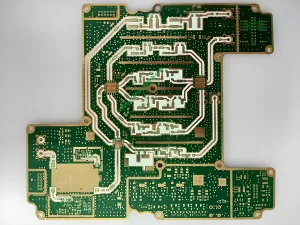

Scenario 2: Airborne Radar Signal Processing Front-End

Airborne environments involve large temperature swings and vibration. This PCB’s low TCDk ensures consistent radar performance across altitudes and temperatures, while the 1.65mm thick, robust construction resists vibrational stress.

Why Choose UGPCB for Your High-Frequency PCB?

-

Материальная экспертиза: We possess in-depth knowledge of processing high-frequency materials like Rogers, ensuring material integrity from storage through fabrication.

-

Advanced Process Capability: Mature processes for blind via registration и depth-controlled milling ensure first-pass success for complex designs.

-

Performance Validation: We provide critical impedance test reports и S-parameter data support using high-end network analyzers, bridging simulation and measurement.

-

Сквозная поддержка: We offer full-cycle technical collaboration—from stack-up & impedance design, DFM -анализ, to volume production—accelerating your time to market.

Ready to Power Your Next RF Project?

Contact a UGPCB engineer today for a comprehensive DFM review and a competitive quote. Submit your stack-up and impedance requirements to start the conversation.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ