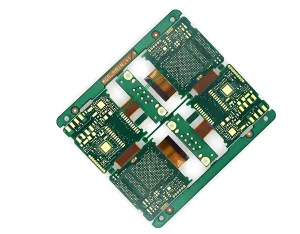

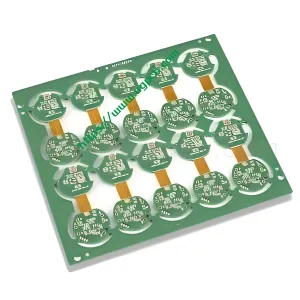

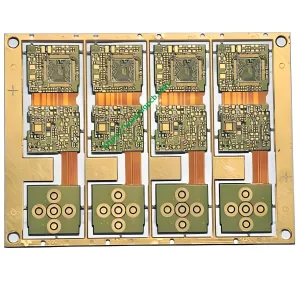

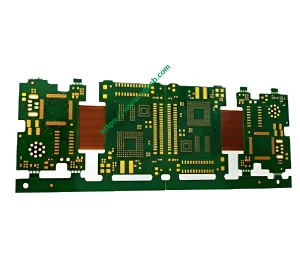

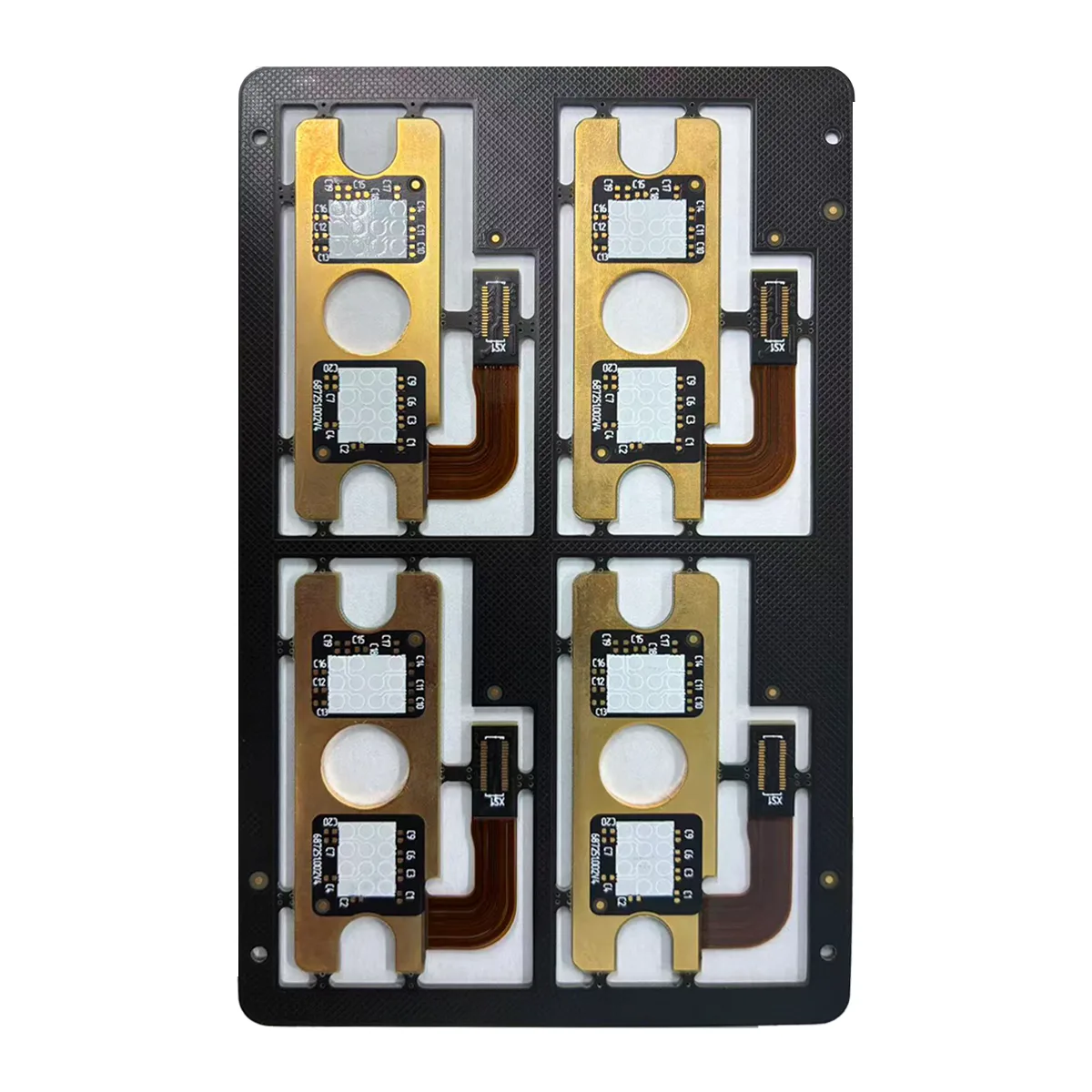

1.UGPCB 4-Layer High Tg Rigid-Flex PCB 제품개요: Redefining High-Reliability Interconnectivity

In modern high-end electronic design, traditional rigid 인쇄 회로 기판 (PCB) are often limited by space and form factor, while Flexible PCBs (FPC) may lack mechanical support. 리지드 플렉스 PCB 기술, an innovative PCB 제조 해결책, perfectly merges the stability of rigid boards with the bendability of flexible circuits. UGPCB 4-Layer High Tg Rigid-Flex PCB, with its precise lamination structure, superior material selection, and demanding surface finish, stands as the ideal PCB solution for complex 3D spatial layouts and harsh operating environments.

2. 과학적 분류 & Core Parameters

-

과학적 분류: 당 IPC 표준 and industry norms, this product is accurately classified as a 4-Layer High Thermal Reliability Rigid-Flex Printed Circuit Board.

-

Core Parameters:

-

Layer Construction: 4 레이어 (4L 리지드 플렉스 PCB)

-

보드 두께: 1.60mm (in rigid areas, including dielectrics and copper)

-

기본 재료: Panasonic RF-777 (35/50µm copper)

-

표면 마감: 동의하다 (무전해 니켈 침지 금) 3µ” + Selective Electroplated Hard Gold 30µ”

-

치수: 126mm * 80mm

-

3. 디자인 필수사항 & Structure Analysis

Successful Rigid-Flex PCB design 중요합니다. This product is designed adhering to these key points:

-

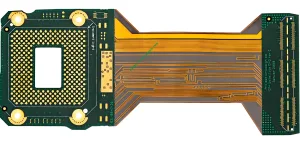

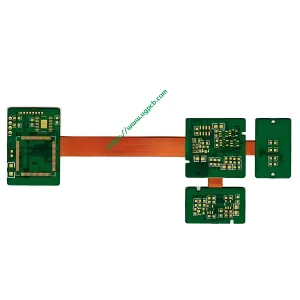

Rigid-to-Flex Transition Zone Design: Bend areas are meticulously simulated, avoiding right and acute angles. Smooth curved traces are implemented to eliminate stress concentration points, a cornerstone of high-reliability PCB design.

-

Stack-up Symmetry: Rigid sections employ a symmetrical lamination stack-up (예를 들어, copper-dielectric-core-dielectric-copper) to prevent warping under thermal stress.

-

재료 호환성: The selected Panasonic RF-777 material has matched Coefficients of Thermal Expansion (CTE) in both rigid and flexible zones, ensuring robust bonding at the interfaces.

Structural Feature: The board is constructed by laminating two rigid outer sections with a multilayer structure containing flexible inner layers, enabling electrical interconnection in three-dimensional space.

이미지 제안 2: A detailed cross-sectional diagram of the board’s layer stack-up, clearly labeling rigid areas, flex areas, 재료, 그리고 두께.

모든 것이 필요합니다: Cross-section diagram of a 4-Layer Rigid-Flex PCB stack-up, showing the integration of rigid FR-4 and flexible polyimide materials.

4. 재료 & 성능

-

핵심 자료: Panasonic RF-777. This is a high-performance laminate specifically optimized for Rigid-Flex PCB fabrication.

-

높은 유리 전이 온도 (Tg): Provides excellent thermal stability, maintaining mechanical and electrical properties during high-temperature soldering (예를 들어, lead-free reflow) and in high-temperature operating environments.

-

낮은 Dk (유전 상수) & Df (소산 인자): Ensures signal integrity for 고주파 PCB 애플리케이션.

-

Superior Dimensional Stability & 화학 저항: Guarantees long-term reliability.

-

-

표면 마감: ENIG 3µ” + Electroplated Hard Gold 30µ”. This combination is a key differentiator.

-

동의하다: Provides a flat, highly solderable surface finish across the entire board, suitable for fine-pitch component assembly.

-

Electroplated Hard Gold: Applied selectively to connector fingers or areas subject to frequent insertion/withdrawal or friction, the 30µ” hard gold layer dramatically increases wear resistance, 내산화성, 접촉 신뢰성, extending connector lifecycle.

-

5. Manufacturing Process Flow

UGPCB employs industry-leading PCB production processes 품질을 보장하기 위해:

-

Laser & Mechanical Drilling: High-precision drilling for varying hole size requirements.

-

홀 금속화 & 도금: Ensures interlayer connectivity.

-

패터닝 & 에칭: Forms precise circuit patterns.

-

라미네이션 & Pressing: Precisely bonds rigid and flexible layers into a single unit under high heat and pressure—the technical core of rigid-flex circuit board processing.

-

표면 마무리: Sequential application of ENIG and selective hard gold plating.

-

Contour Routing & 테스트: Final outline achieved via CNC and laser routing, followed by AOI (자동 광학 검사), electrical testing, and flex-cycle reliability testing.

이미지 제안 3: An image of a modern PCB production line, focusing on a lamination press or AOI inspection station.

모든 것이 필요합니다: UGPCB’s modern Rigid-Flex PCB production line featuring high-precision lamination and inspection equipment for quality assurance.

6. 주요 장점 & 제품 기능

-

3D Design Freedom: Solves complex spatial layout challenges, reduces connectors and cabling, and enhances system reliability.

-

Exceptional Mechanical & 전기적 성능: High-strength flex joints withstand thousands of dynamic bend cycles; shortened signal paths reduce loss.

-

High Reliability Assurance: High Tg material and dual surface finish ensure stable long-term operation in harsh environments (고온, 습기, 진동).

-

무게 & Size Reduction: Contributes to overall device miniaturization and lightweight design.

7. 일반적인 응용 프로그램

이것 4-Layer Rigid-Flex PCB is the preferred PCB component for demanding sectors:

-

산업용 & 자동차 전자: Vibration-resistant connections in control systems, automotive sensors, and Engine Control Units (씌우다).

-

의료 기기: 내시경, portable monitors, hearing aids—devices requiring precise, 믿을 수 있는, and bendable interconnects.

-

항공우주 & 방어: Avionics and military electronics where weight, 공간, and reliability are paramount.

-

고급 소비자 전자 제품: Camera module connections in smartphones, hinge connections in wearables, advanced digital cameras.

8. UGPCB를 선택하는 이유는 무엇입니까??

As a professional PCB 제조업체, UGPCB 전문 리지드 플렉스 PCB 기술, offering full-spectrum capabilities from PCB 설계 지원 그리고 정밀도 PCB 제작 to rigorous PCB 테스트. We commit to:

-

Expert Engineering Support: Free 제조용 PCB 설계 consultation for your project.

-

Consistent, 믿을 수 있는 품질: Every board undergoes stringent reliability testing.

-

경쟁력있는 가격 & Lead Times: Optimized supply chain and production management deliver high-value PCB 솔루션.

Contact UGPCB today for a free prototype evaluation and quote. Let our professional PCB 제조 services power your innovative product to market success.

UGPCB 로고

UGPCB 로고