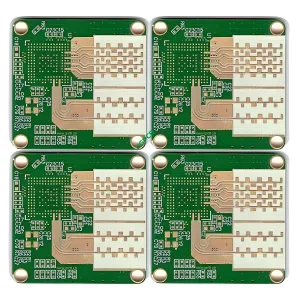

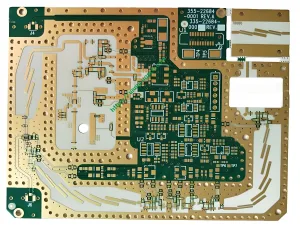

Overview of Rogers 5880 PCB

The Rogers 5880 PCB is a high-performance placă de circuit designed for demanding applications in microwave, instrumentation, and communication. Utilizing Rogers 5880 substrat, this product offers exceptional signal integrity and reliability. With dielectric constants of 2.2 and thickness options ranging from 0.2mm to 4.8mm, it provides flexibility for various design requirements. The surface treatment is Immersion Gold, ensuring excellent solderability and corrosion resistance. The special processes include Teflon PCB multistrat and Countersink PCB, enhancing its performance in high-frequency applications.

Definiție și specificații cheie

A Rogers 5880 PCB is defined by its use of the Rogers 5880 substrat, known for its low dielectric constant and high signal fidelity. The dielectric constant is 2.2, which is ideal for maintaining signal integrity at high frequencies. The thickness can vary from 0.2mm to 4.8mm, allowing for customization based on specific application needs. The surface treatment is Immersion Gold, providing a robust and reliable finish. The base copper weight is 0.5OZ, with a finished thickness of 1OZ, ensuring efficient conductivity. Special processes like Teflon multilayer and Countersink further enhance the PCB’s performance in high-frequency environments.

Considerații de proiectare

When designing a Rogers 5880 PCB, Trebuie luați în considerare mai mulți factori:

- Constanta dielectrică: The 2.2 dielectric constant of Rogers 5880 is optimal for high-frequency signals, reducing delay and loss.

- Grosime: The wide range of thickness options (0.2mm – 4.8mm) allows for flexibility in design, catering to different application requirements.

- Grosime de cupru: The base and finished copper weights ensure that the PCB can handle high currents and maintain signal integrity.

- Tratament de suprafață: Immersion Gold provides excellent solderability and protects against corrosion, essential for long-term reliability.

- Procese speciale: Techniques like Teflon multilayer and Countersink are crucial for enhancing performance in high-frequency and microwave applications.

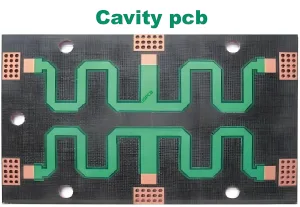

Principiul de lucru

The Rogers 5880 PCB operates based on the principle of controlled impedance and minimal signal loss. The low dielectric constant of the substrate ensures that signals travel with minimal delay and loss, menținerea integrității lor. Controlul precis asupra grosimii și a greutății cuprului permite o impedanță constantă, ceea ce este esențial pentru transmisia semnalului de înaltă frecvență. The Immersion Gold surface treatment provides a reliable connection point for components, Asigurarea transferului eficient al semnalului.

Aplicații

Rogers 5880 PCBs are used in a variety of applications that require high-frequency performance and signal integrity:

- Microwave: Ideal for radar systems, Comunicări prin satelit, and other microwave applications where signal purity is paramount.

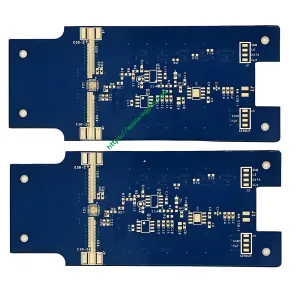

- Instrumentation: Used in precision measurement and testing equipment where accurate signal processing is crucial.

- Comunicare: Suitable for high-speed data transmission and reception in communication devices.

Clasificare

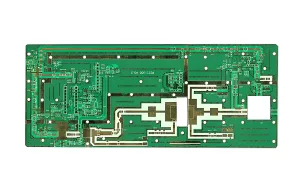

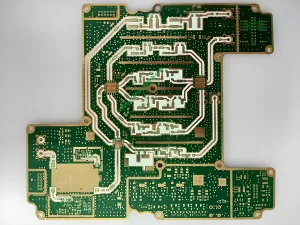

Rogers 5880 PCBs can be classified based on several criteria:

- Număr de straturi: Variind de la 1 layer to 24 straturi, În funcție de complexitatea circuitului.

- Grosime: Options from 0.2mm to 4.8mm allow for customization based on specific application needs.

- Procese speciale: Standard and specialized versions, such as those using Teflon multilayer or Countersink techniques.

Proprietăți materiale

The key properties of the Rogers 5880 substrate include:

- Constantă dielectrică scăzută: Asigură întârzierea și pierderea semnalului minim, making it suitable for high-frequency applications.

- Gama largă de grosime: Permite flexibilitate în proiectare, catering to different application requirements.

- Excellent Solderability: The Immersion Gold surface treatment provides a reliable and robust connection point for components.

- High Signal Fidelity: Menține integritatea semnalului chiar și la frecvențe înalte, asigurând performanțe fiabile.

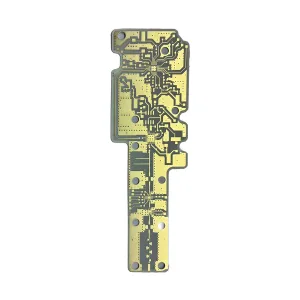

Proces de producție

The production of a Rogers 5880 PCB involves several steps:

- Selectarea materialelor: Choosing the Rogers 5880 substrate for its low dielectric constant and high signal fidelity.

- Proiectarea circuitului: Crearea aspectului circuitului cu considerente pentru performanța de înaltă frecvență și integritatea semnalului.

- Gravură: Eliminarea cuprului inutil pentru a crea modelul de circuit dorit.

- Laminare: Legarea mai multor straturi împreună sub presiune și temperatură ridicată pentru a asigura o conexiune puternică și fiabilă.

- Finisarea suprafeței: Applying Immersion Gold to enhance solderability and corrosion resistance.

- Procese speciale: Utilizing techniques like Teflon multilayer and Countersink to further enhance performance in high-frequency applications.

- Testarea și controlul calității: Asigurarea că produsul final îndeplinește toate specificațiile și standardele.

Folosiți scenarii

Rogers 5880 PCBs are used in scenarios where high-frequency performance and signal integrity are critical:

- Microwave Communication Systems: Ensuring clear and reliable signal transmission in radar and satellite communication systems.

- Precision Measurement Instruments: Providing accurate and reliable signal processing in scientific and industrial measurement equipment.

- High-Speed Data Communication: Facilitating rapid and reliable data transfer in modern communication devices.

În concluzie, the Rogers 5880 PCB is a high-performance circuit board designed for demanding applications in microwave, instrumentation, and communication. Its low dielectric constant, Gama largă de grosime, and excellent signal fidelity make it an ideal choice for maintaining signal integrity at high frequencies.

LOGO UGPCB

LOGO UGPCB