1. Эволюция технологии и инновации PCB

The печатная плата (Печатная плата) служит “мать электронных продуктов,” Включение механической фиксации и электрического соединения компонентов через медные следы и прокладки. Современные ПХБ развивались от однослойных досок до взаимосвязанного соединения высокой плотности (ИЧР) и многослойные доски, вызвано требованиями высокой производительности, миниатюризация, и надежность.

Ключевые драйверы рынка:

- Спрос серверов AI вырос 60% Госпожа в 2025, Повышение HDI и Многослойная печатная плата принятие.

- Проникновение автомобильной электроники, Особенно в EVS, подпитывает высокий рост печатной платы.

- 10-слойная плата первого порядка от UGPCB уменьшает потерю сигнала на 42% Использование 2 -мильных трассов и технологии лазерной микровий.

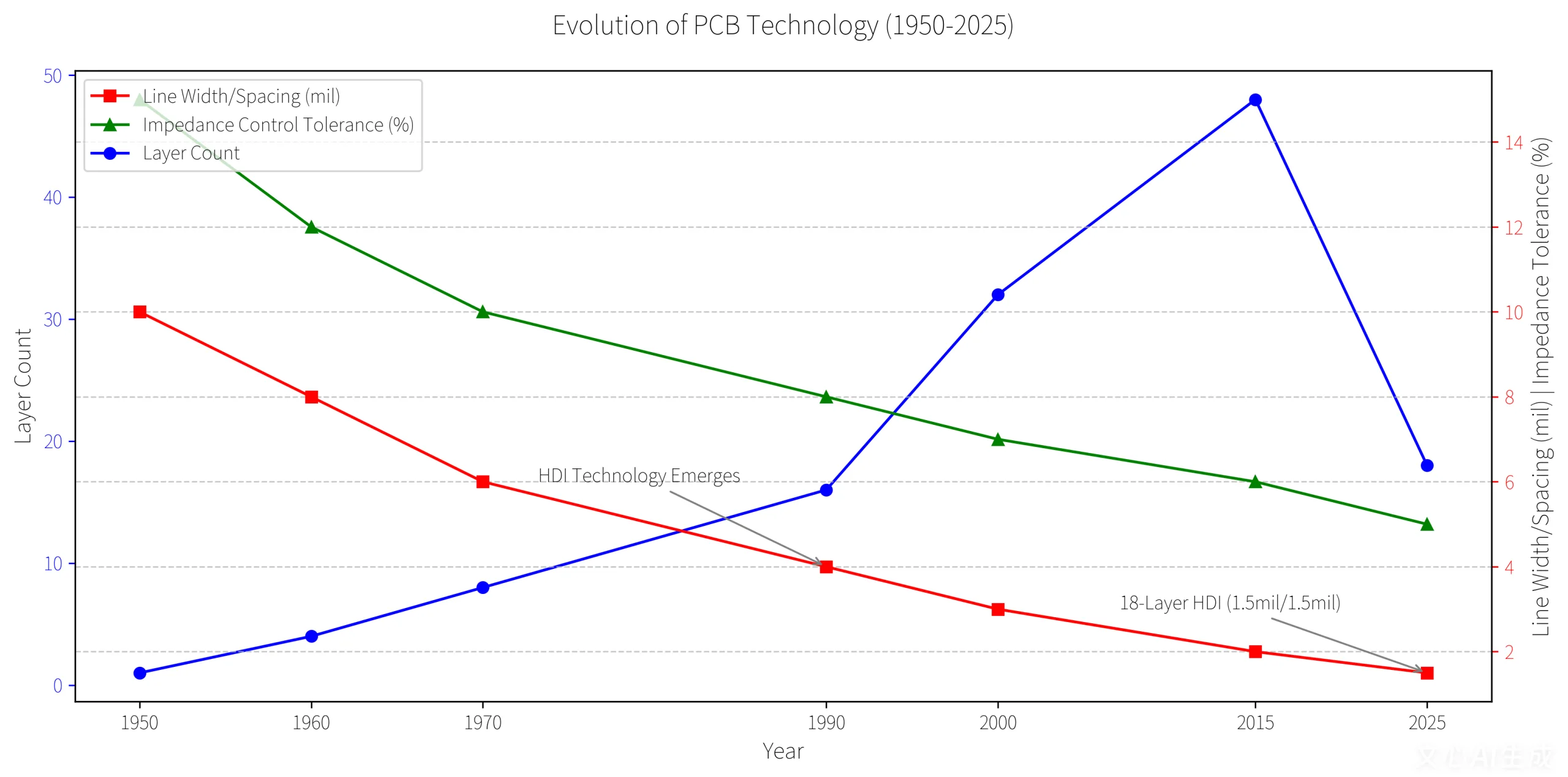

Технические прорывы:

- Ширина трассировки/расстояние до 1,5 млн/1,5 млн. (Среднее значение в отрасли: 3мил).

- Контрольная толерантность к импедансу ± 5% (Превышает отраслевые стандарты 10%).

2. Классификация и приложения PCB

2.1 На основе слоев классификация

Однослойные печатные платы: Простые дизайны (например, игрушки, силовые адаптеры).

Двойные платы: Использует VIAS для взаимодействия; Идеально подходит для маршрутизаторов и домашних приборов.

Многослойные печатные платы (3+ Слои): Проекты высокой плотности для смартфонов, Автомобильные системы, и промышленные контроллеры.

2.2 Материал & Основанная на процессах классификация

Жесткие печатные платы: Подложка FR-4 для устройств с фиксированной формой (телефоны, Телевизоры).

Гибкие печатные платы (ФПК): На основе полиимидов для сгибаемых приложений (Экранные кабели, носимые устройства).

Жесткие платы: Сочетает жесткие и гибкие секции для сложных сборок (беспилотники, медицинское оборудование).

3. Требования к конкретным приложениям

3.1 Бытовая электроника

- Смартфоны: 12-Слои жесткие печатные платы для процессоров, камеры, и радиочастотные модули.

- Ноутбуки: 6-10 платы слоев для процессоров; FPCS для соединений аккумулятора.

3.2 Промышленная электроника

- ПЛК контроллеры: 4-6 Слои ПХБ с сопротивлением EMC для управления двигателем.

- Датчики: Двойные платы со стабильной передачей сигнала в суровых условиях.

3.3 Автомобильная электроника

- Управление аккумулятором EV: Многослойные печатные платы для мониторинга напряжения/температуры.

- ADAS Systems: Платы с высокой надежностью с ответом на миллисекунд.

3.4 Высококачественные приложения

- 5G Базовые станции: 8-12 РЧ-платы слоя для высокочастотной целостности сигнала.

- Медицинские устройства: Многослойные печатные платы с биосовместимыми материалами для машин ЭКГ.

4. Рыночные данные и прогнозы роста

- Глобальный рынок ПКБ: 155.38Б 2037.

- Доски HDI: 33.4% Доля рынка по 2037, управляется смартфонами и серверами искусственного интеллекта.

- Автомобильные печатные платы: 18.79Б 2035 (Кагр 5.5%).

Доминирование Китая: Учитывает 50% глобального производства; Высококачественные печатные платы до достижения 40% поделиться 2025.

5. SCB и SMT Синергия

Дизайн печатной платы и СМТ (Технология поверхностного крепления) взаимозависимы:

- ПХБ обеспечивают точные макету припоя для компонентов SMT (например, 0402 резисторы: 0.4мм × 0,2 мм).

- SMT включает сборку высокой плотности, такие как BGA Chips на платы с смартфонами.

Преимущество UGPCB: LPKF Лазерные системы визуализации достигают точность выравнивания ± 25 мкм, критическое для производства HDI.

6. Будущие проблемы и тенденции

Затратное давление:

- Цены на медь повышаются 15% в 2025;Медный ламинат (Ccl) расходы выросли 8-12%.

- МСП СДЕРЖИВАНИЕ, Ускорение консолидации промышленности.

Технологические сдвиги:

- Растущий спрос на 8-16 СЛОВОВЫЕ ПХБ и ИК -субстраты (размер рынка: $45Б 2025).

- Низкая мощность, Высокопроводящие материалы для экологически чистых дизайнов.

Глобальное расширение:

- Производители печатной платы, инвестирующие в Юго -Восточную Азию (Вьетнам, Таиланд) для экономической эффективности и предотвращения тарифов.

Заключение

Индустрия печатных плат остается ключевой к глобальной электронике, управляется ИИ, автомобильный, и 5G Инновации. Компании должны расставлять приоритеты в технических обновлениях, Диверсификация цепочки поставок, и зеленое производство, чтобы процветать на фоне волатильности стоимости и региональной конкуренции.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ