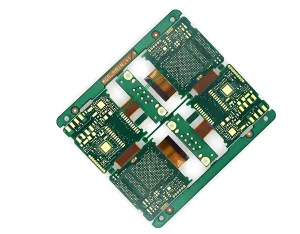

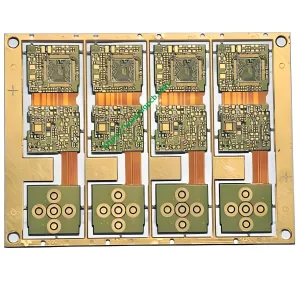

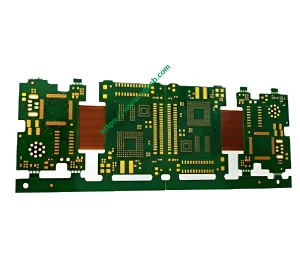

1.UGPCB 4-Layer High Tg Rigid-Flex PCB Обзор продукта: Redefining High-Reliability Interconnectivity

In modern high-end electronic design, traditional rigid Печатные платы (печатные платы) are often limited by space and form factor, while Flexible PCBs (FPCS) may lack mechanical support. Жестко-гибкая печатная плата технология, an innovative Производство печатных плат solution, perfectly merges the stability of rigid boards with the bendability of flexible circuits. UGPCB 4-Layer High Tg Rigid-Flex PCB, with its precise lamination structure, superior material selection, and demanding surface finish, stands as the ideal PCB solution for complex 3D spatial layouts and harsh operating environments.

2. Scientific Classification & Core Parameters

-

Scientific Classification: Пер Стандарты IPC and industry norms, this product is accurately classified as a 4-Layer High Thermal Reliability Rigid-Flex Printed Circuit Board.

-

Core Parameters:

-

Layer Construction: 4 Слои (4L жестко-гибкая печатная плата)

-

Толщина доски: 1.60мм (in rigid areas, including dielectrics and copper)

-

Базовый материал: Panasonic RF-777 (35/50µm copper)

-

Поверхностная отделка: СОГЛАШАТЬСЯ (Химическое никель, иммерсионное золото) 3µ” + Selective Electroplated Hard Gold 30µ”

-

Размеры: 126мм * 80мм

-

3. Design Essentials & Structure Analysis

Successful Rigid-Flex PCB design имеет решающее значение. This product is designed adhering to these key points:

-

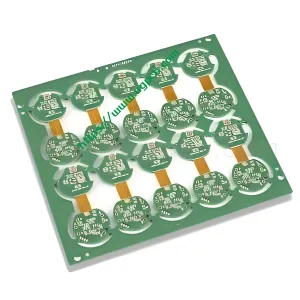

Rigid-to-Flex Transition Zone Design: Bend areas are meticulously simulated, avoiding right and acute angles. Smooth curved traces are implemented to eliminate stress concentration points, a cornerstone of high-reliability PCB design.

-

Stack-up Symmetry: Rigid sections employ a symmetrical lamination stack-up (например, copper-dielectric-core-dielectric-copper) to prevent warping under thermal stress.

-

Совместимость материала: The selected Panasonic RF-777 material has matched Coefficients of Thermal Expansion (КТР) in both rigid and flexible zones, ensuring robust bonding at the interfaces.

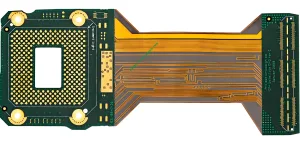

Structural Feature: The board is constructed by laminating two rigid outer sections with a multilayer structure containing flexible inner layers, enabling electrical interconnection in three-dimensional space.

Image Suggestion 2: A detailed cross-sectional diagram of the board’s layer stack-up, clearly labeling rigid areas, flex areas, материалы, и толщина.

Alt Tag: Cross-section diagram of a 4-Layer Rigid-Flex PCB stack-up, showing the integration of rigid FR-4 and flexible polyimide materials.

4. Материалы & Производительность

-

Основной материал: Panasonic RF-777. This is a high-performance laminate specifically optimized for Rigid-Flex PCB fabrication.

-

Высокая температура перехода стекла (Тг): Provides excellent thermal stability, maintaining mechanical and electrical properties during high-temperature soldering (например, lead-free reflow) and in high-temperature operating environments.

-

Низкий DK (Диэлектрическая проницаемость) & Дф (Коэффициент рассеяния): Ensures signal integrity for высокочастотная печатная плата приложения.

-

Superior Dimensional Stability & Химическая устойчивость: Guarantees long-term reliability.

-

-

Поверхностная отделка: ENIG 3µ” + Electroplated Hard Gold 30µ”. This combination is a key differentiator.

-

СОГЛАШАТЬСЯ: Provides a flat, highly solderable surface finish across the entire board, suitable for fine-pitch component assembly.

-

Electroplated Hard Gold: Applied selectively to connector fingers or areas subject to frequent insertion/withdrawal or friction, the 30µ” hard gold layer dramatically increases wear resistance, стойкость к окислению, и надежность контактов, extending connector lifecycle.

-

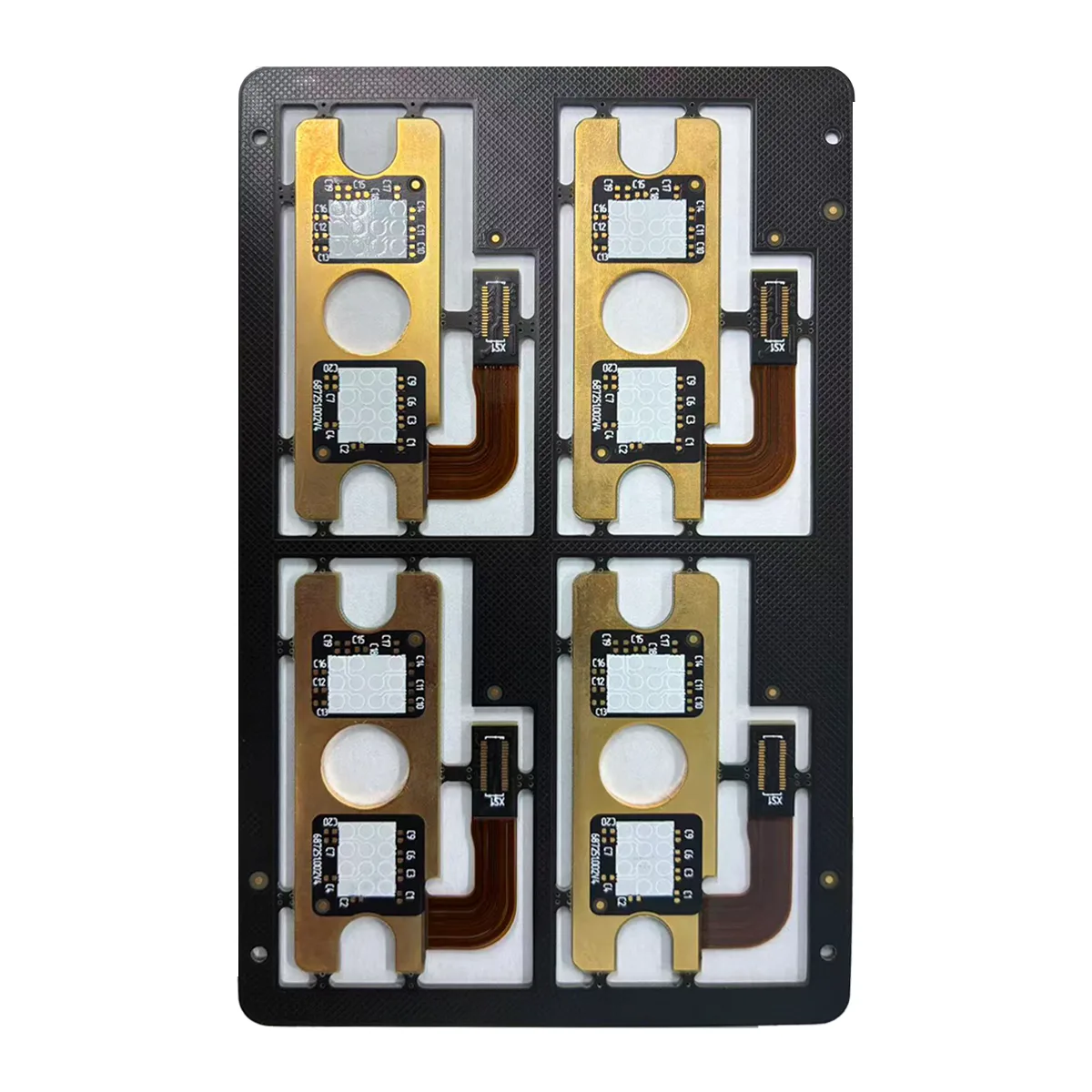

5. Manufacturing Process Flow

UGPCB employs industry-leading PCB production processes to ensure quality:

-

Laser & Mechanical Drilling: High-precision drilling for varying hole size requirements.

-

Hole Metallization & Покрытие: Ensures interlayer connectivity.

-

Patterning & Офорт: Forms precise circuit patterns.

-

Ламинирование & Pressing: Precisely bonds rigid and flexible layers into a single unit under high heat and pressure—the technical core of rigid-flex circuit board processing.

-

Поверхностная отделка: Sequential application of ENIG and selective hard gold plating.

-

Contour Routing & Тестирование: Final outline achieved via CNC and laser routing, followed by АОИ (Автоматическая оптическая проверка), electrical testing, and flex-cycle reliability testing.

Image Suggestion 3: An image of a modern PCB production line, focusing on a lamination press or AOI inspection station.

Alt Tag: UGPCB’s modern Rigid-Flex PCB production line featuring high-precision lamination and inspection equipment for quality assurance.

6. Ключевые преимущества & Особенности продукта

-

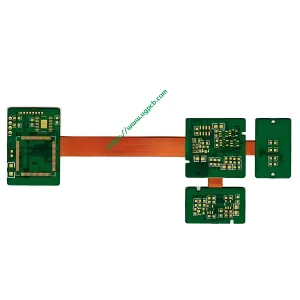

3D Design Freedom: Solves complex spatial layout challenges, reduces connectors and cabling, and enhances system reliability.

-

Exceptional Mechanical & Электрические характеристики: High-strength flex joints withstand thousands of dynamic bend cycles; shortened signal paths reduce loss.

-

High Reliability Assurance: High Tg material and dual surface finish ensure stable long-term operation in harsh environments (высокая температура, влажность, вибрация).

-

Weight & Size Reduction: Contributes to overall device miniaturization and lightweight design.

7. Типичные приложения

Этот 4-Layer Rigid-Flex PCB is the preferred PCB component for demanding sectors:

-

Промышленный & Автомобильная электроника: Vibration-resistant connections in control systems, automotive sensors, and Engine Control Units (КРЫШКА).

-

Медицинские устройства: Эндоскопы, portable monitors, hearing aids—devices requiring precise, надежный, and bendable interconnects.

-

Аэрокосмическая промышленность & Оборона: Avionics and military electronics where weight, космос, and reliability are paramount.

-

High-End Consumer Electronics: Camera module connections in smartphones, hinge connections in wearables, advanced digital cameras.

8. Почему выбирают UGPCB?

As a professional Производитель печатных плат, UGPCB specializes in Жестко-гибкая печатная плата технология, offering full-spectrum capabilities from Поддержка проектирования печатных плат and precision Изготовление печатной платы to rigorous Тестирование печатных плат. We commit to:

-

Expert Engineering Support: Free PCB design for manufacturing consultation for your project.

-

Consistent, Reliable Quality: Every board undergoes stringent reliability testing.

-

Competitive Pricing & Lead Times: Optimized supply chain and production management deliver high-value PCB solutions.

Contact UGPCB today for a free prototype evaluation and quote. Let our professional Производство печатных плат services power your innovative product to market success.

ЛОГОТИП УГКПБ

ЛОГОТИП УГКПБ