UGPCB PWB Manufacturing: Comprehensive Guide to High-Quality PCB Solutions

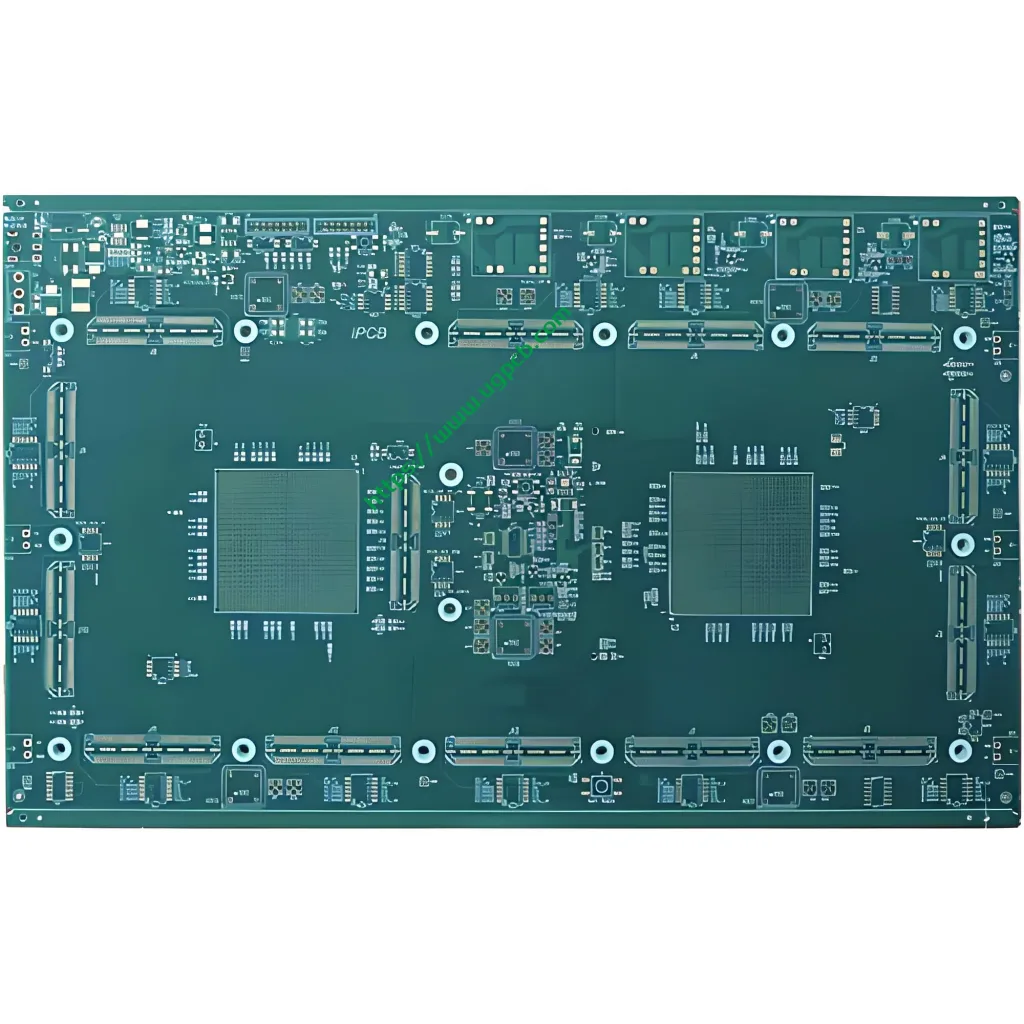

UGPCB specializes in PWB (Printed Wiring Board) fabricație, offering a wide range of customizable PCB solutions for diverse industries. Our products are engineered to meet stringent quality standards, supporting applications from consumer electronics to high-reliability sectors like automotive and aerospace. With capabilities spanning 2 la 100 straturi, thicknesses from 0.13mm to 8.0mm, and advanced materials like FR-4 and High TG FR-4, we deliver robust, de înaltă performanță PCB -uri that ensure reliability and efficiency in every application. This overview introduces the core aspects of our PWB manufacturing process, emphasizing our commitment to precision and innovation in the PCB industry.

What is PWB? Definition and Basics

PWB, or Printed Wiring Board, refers to the foundational component used to mechanically support and electrically connect componente electronice. Unlike the broader term PCB (Placă de circuit tipărită), which often includes assembled boards, PWB specifically denotes the bare board before component attachment. UGPCB’s PWB products serve as the backbone for electronic systems, facilitating signal transmission and power distribution. Key parameters include layer counts (2-100 straturi), finished thickness (0.13mm-8.0mm), and copper thickness (standard 1 oz internal and external), ensuring versatility for various Design PCB needs. This definition highlights the critical role of PWB in modern electronics, bridging design and functionality.

Working Principle of PWB

PWBs operate by using conductive copper traces etched onto insulating substrates to create electrical pathways between components. The board’s layers—ranging from simple 2-layer designs to complex 100-layer configurations—allow for efficient signal routing and noise reduction. De exemplu, in multilayer PCBs, inner layers handle power and ground planes, while outer layers connect components. Surface treatments like Gold, Sângera (Hot Air Solder Leveling), PECVD (Nano-protecție plasmatică) și OSP (Organic Solderability Preservative) enhance conductivity and solderability, ensuring reliable performance in applications such as industrial control systems or automotive electronics. This principle underscores how UGPCB’s PWBs enable seamless electronic functionality through precise electrical interconnection.

Design Key Points for Optimal Performance

Designing a PWB requires attention to critical parameters to avoid issues like signal interference or manufacturing defects. Key considerations include:

-

Trace and Space Minimization: With a minimum trace and space of 3mil (0.075mm), UGPCB supports high-density designs for advanced PCB applications, such as high-speed computing or compact automotive modules.

-

Selectarea materialelor: Using FR-4 and High TG FR-4 materials ensures thermal stability and mechanical strength, crucial for environments with high temperatures or vibrations.

-

Layer Stack-up: Proper layer planning (din 2 la 70 straturi) helps manage impedance and reduce EMI, essential for reliable PCB performance in aerospace or industrial settings.

-

Surface Treatment Choice: Options like Gold for corrosion resistance, HASL for cost-effectiveness, PECVD (Nano-protecție plasmatică) or OSP for environmental friendliness cater to specific PCB (Asamblu placă de circuit imprimat) cerințe. By focusing on these elements, designers can achieve efficient, manufacturable boards that meet industry standards.

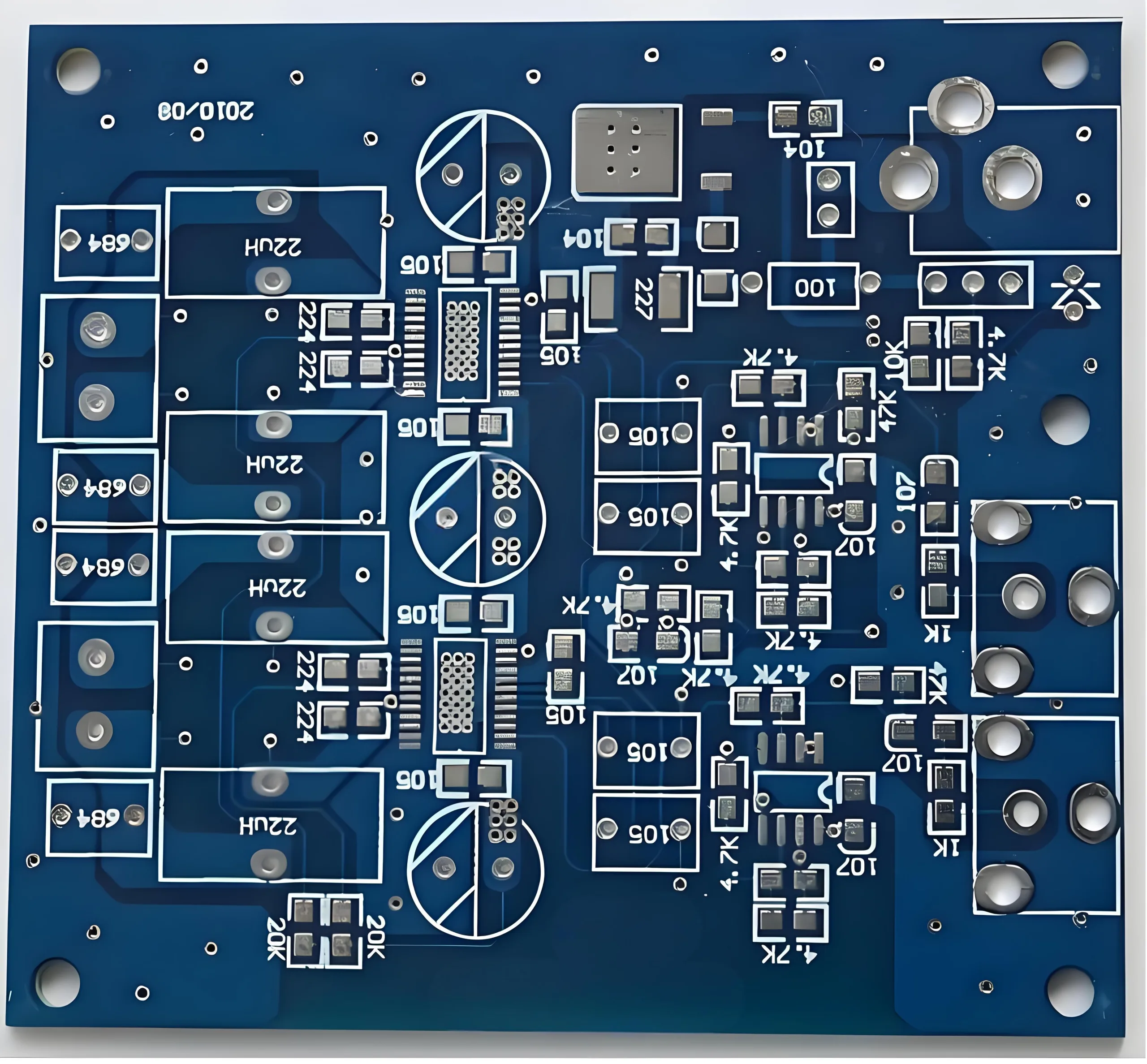

Materials Used in PWB Construction

UGPCB employs high-quality materials to ensure durability and performance:

-

FR-4: A standard epoxy-glass laminate offering excellent electrical insulation and mechanical stability, ideal for general-purpose PCB manufacturing.

-

High TG FR-4: This material provides enhanced glass transition temperature, making it suitable for high-temperature applications like automotive engine controls or industrial power systems.

These materials are complemented by copper foils (1 oz thickness for reliable conductivity) and solder masks in colors like green, negru, blue, and white, which aid in identification and protection during the PCBA process. This material selection ensures that our PWBs meet rigorous environmental and operational demands.

Performance Characteristics and Specifications

UGPCB’s PWBs are designed for superior performance across various metrics:

-

Performanță electrică: Low signal loss and stable impedance, supported by precise copper thickness and minimal trace/space dimensions, ensure efficient operation in PCB de înaltă frecvență aplicații.

-

Thermal and Mechanical Stability: High TG FR-4 materials allow operation in temperatures exceeding standard ranges, vital for automotive PCB and airplane PCB uses where thermal cycling is common.

-

Fiabilitate: With finished thickness options from 0.4mm (for flexible designs) to 6.0mm (for rugged applications), our boards withstand mechanical stress and environmental factors, backed by surface treatments that prevent oxidation and improve solder joint integrity. These characteristics make UGPCB’s products a trusted choice for critical electronic systems.

Structural Description of PWB

The structure of a PWB consists of multiple layers laminated together, each serving a specific function:

-

Core and Prepreg Layers: The core provides rigidity, while prepreg (pre-impregnated) layers bond the cores in multilayer setups, enabling complex routing for advanced PCB designs.

-

Copper Layers: De obicei, 1 oz copper is used for both internal and external layers, forming the conductive paths. Layer counts from 2 la 70 allow for scalable complexity, from simple single-sided boards to high-density interconnect (HDI) PCB -uri.

-

Solder Mask and Silkscreen: Applied in colors like green, negru, blue, or white, the solder mask insulates traces, and silkscreen adds labels for component placement during PCBA. This layered structure ensures optimal electrical performance and durability in diverse applications.

Classification of PWB Products

UGPCB classifies PWBs based on key parameters to cater to different needs:

-

By Layer Count: Ranging from 2-layer boards for basic electronics to 70-layer boards for complex systems like servers or aviation controls.

-

Prin cerere: Categories include industrial PCB for machinery, automotive PCB for vehicles, and airplane PCB for aerospace, each tailored with specific materials and tolerances.

-

By Surface Treatment: Options like Gold for high-reliability, HASL for general use, or OSP for lead-free PCBA requirements. This classification helps customers select the right PCB solution for their project, ensuring compatibility and performance.

Production Process Overview

The manufacturing of PWBs at UGPCB follows a streamlined process to ensure quality and consistency:

-

Design and Fabrication: Using CAD tools, designs are translated into photoplots, considering parameters like min trace/space of 1.5mil.

-

Pregătirea materialelor: FR-4 or High TG FR-4 substrates are cut and cleaned.

-

Lamination and Drilling: Layers are bonded under heat and pressure, and holes are drilled for vias and components.

-

Copper Plating and Etching: Copper is deposited and etched to form circuits, with thickness controlled to 1 oz standards.

-

Tratament de suprafață: Application of Gold, Sângera, or OSP to protect and prepare the board for PCBA.

-

Testing and Inspection: Electrical tests and visual checks verify compliance with specifications, such as thickness tolerance (0.13mm-8.0mm). This efficient workflow supports high-volume PCB manufacturing while maintaining precision.

Applications and Usage Scenarios

UGPCB’s PWBs are utilized in a broad spectrum of industries, demonstrating their versatility:

-

Electrical Apparatus: Used in household appliances and power tools, where reliable PCB performance ensures safety and longevity.

-

Industrial PCB: Applied in automation systems and control panels, benefiting from high layer counts and thermal resistance.

-

Automotive PCB: Integrated into engine management and infotainment systems, leveraging High TG FR-4 for temperature endurance.

-

Airplane PCB: Employed in avionics and navigation equipment, where multilayer designs and strict tolerances meet aerospace standards. These scenarios highlight how our PCBA-ready boards drive innovation across sectors, providing dependable solutions for complex electronic challenges.

Product Features and Advantages

UGPCB’s PWB manufacturing stands out due to its exceptional features:

-

Customizability: With options for layer counts (2-100), colors, and thicknesses, we offer tailored PCB solutions for any project.

-

Precizie înaltă: Min trace/space of 1.5 mil enables compact, high-density designs, ideal for modern electronics.

-

Durabilitate: Materials like High TG FR-4 ensure resistance to heat and stress, extending product life in demanding environments.

-

Eficiența costurilor: Efficient production processes and surface treatment choices like OSP reduce overall PCBA costs. These advantages make UGPCB a leader in PCB manufacturing, supporting everything from prototyping to mass production with reliability and innovation.

LOGO UGPCB

LOGO UGPCB