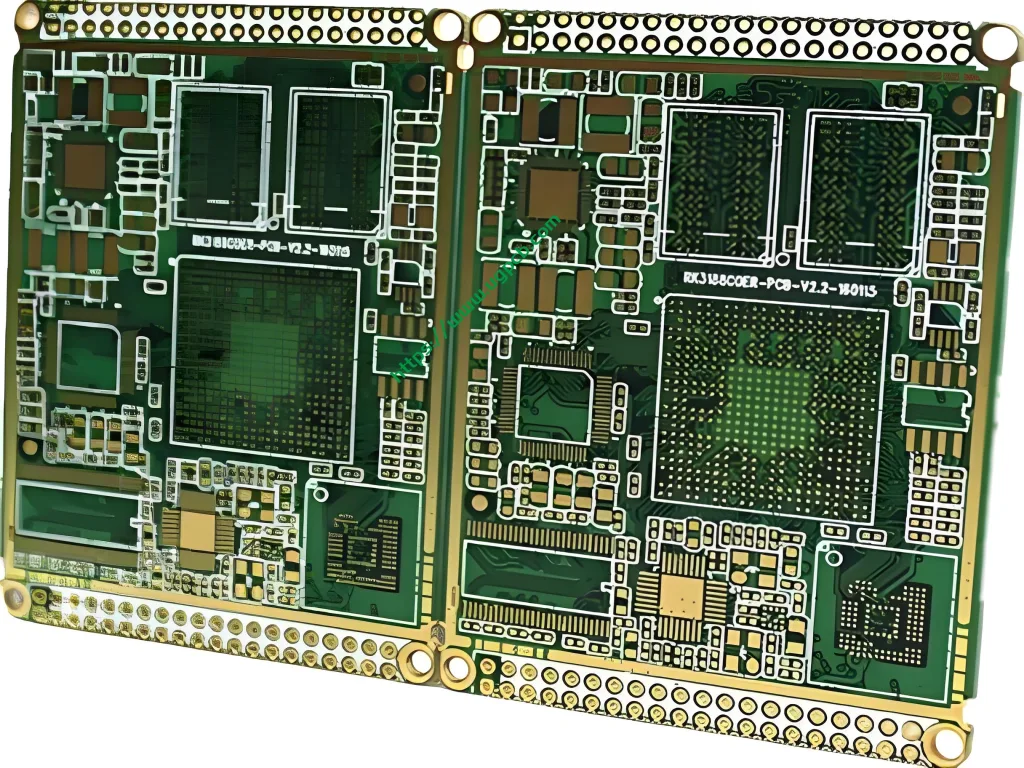

UGPCB Double-Sided Gold-Plated PCB Product Overview

UGPCB’s gold-plated double-sided PCB board represents the pinnacle of accessibility and performance in circuit imprimé technologie. Designed for engineers and creators who demand reliability without the complexity of multi-layer boards, this product leverages the proven Immersion Gold (ACCEPTER) surface treatment to ensure robust connections and exceptional signal integrity. With a standard 1.2mm thickness, 1OZ copper cladding, and fine 6mil trace capabilities, it serves as the perfect substrate for a vast array of digital PCB applications, from prototyping to full-scale production.

What is a Gold-Plated (Immersion Or) Double-Sided PCB?

Definition and Basic Concept

UN PCB double face is a circuit board that features conductive copper layers on both its top and bottom surfaces, allowing for more complex and dense circuit routing compared to single-sided boards. Le terme “gold-plated” in our context specifically refers to the Immersion Or (ACCEPTER) finition de surface. This is a critical final step in the Fabrication de circuits imprimés process where a thin layer of gold is chemically deposited over a nickel barrier layer on the copper traces. This combination provides a flat, oxidation-resistant, and highly solderable surface, making it ideal for double-sided PCB fabrication and subsequent Assemblage PCBA.

In-Depth Specifications and Material Composition

The Building Blocks of Quality

The superior performance of our double-sided boards is rooted in the careful selection of materials and precise control of parameters:

-

Core Material: High-quality FR4, a flame-retardant glass-reinforced epoxy laminate. This material offers an excellent balance of mechanical strength, isolation électrique, et la rentabilité.

-

Board Structure: 2 Calques of copper foil, firmly bonded to the FR4 substrate.

-

Traitement de surface: Immersion Or (ACCEPTER). This process creates a flat surface crucial for modern components, protects the underlying copper, and provides a long shelf life.

-

Épaisseur du cuivre: 1once (approximately 35µm), a standard and robust weight that handles typical current loads in digital circuits effectively.

-

Épaisseur finie: 1.2mm, offering a rigid and durable board structure for most applications.

-

Critical Design Rules: Minimum Trace/Space of 6mil (0.15mm), enabling a good level of design density for complex digital circuits.

-

Masque de soudure: Available in Green or White, providing insulation and protection against oxidation and solder bridges.

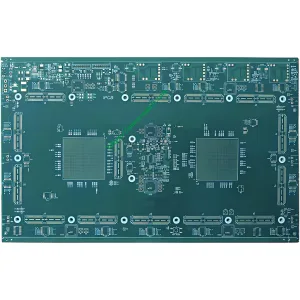

Key Advantages and Product Features: Why Choose UGPCB’s Immersion Gold PCB?

Unmatched Reliability and Performance

Choosing our gold-plated double-sided PCB translates to tangible benefits for your project:

-

Superior Flatness and Solderability: The ENIG finish is exceptionally flat, which is vital for reliably soldering fine-pitch components like BGAs and QFNs. This directly reduces defects in your PCB processus.

-

Excellent Oxidation Resistance: The gold layer is inert, preventing the copper from tarnishing over time. This ensures a reliable surface for soldering even after prolonged storage, making your Prototype de PCB and production inventory more manageable.

-

Stable Contact Surface for Connectors: The hard, durable gold surface is ideal for edge connectors and test points, providing a low-resistance, wear-resistant contact interface.

-

Dual-Sided Routing Capability: Effectively doubles the available area for routing traces compared to a single-sided board, allowing for more compact and efficient digital circuit board dessins.

-

Rentabilité: For designs that don’t require the complexity of a 4-layer board, the double-sided Carte FR4 with ENIG finish offers the best performance-to-cost ratio for a wide range of applications.

Typical Applications and Use Cases: Where is This PCB Used?

Powering the Digital World

The versatility of our double-sided immersion gold PCB makes it a go-to solution across numerous industries:

-

Consumer Digital Electronics: Smart home controllers, IoT sensor nodes, appareils portables, and audio equipment.

-

Électronique automobile: Dashboard controllers, sensor modules, and lighting control units.

-

Industrial Control Systems: PLC I/O modules, entraînements à moteur, and measurement instrumentation.

-

Télécommunications: Routeurs, commutateurs, and network interface modules.

-

Dispositifs médicaux: Patient monitoring equipment and diagnostic tools where reliability is paramount.

-

Prototyping and R&D: The ideal choice for functional PCB prototypes that closely mimic final production performance.

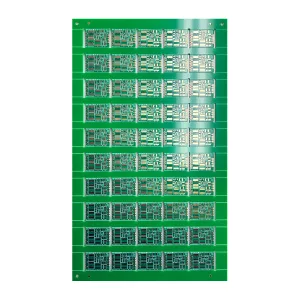

The Manufacturing Workflow: A Glimpse into Precision Engineering

De la conception à la livraison

The production of a high-quality double-sided PCB is a meticulous process:

-

Préparation des matériaux & Forage: The FR4 panel is prepared, and via holes are precision-drilled to create interconnections between layers.

-

Plating Through Hole (PTH): A conductive layer is chemically deposited inside the drilled holes to establish electrical connectivity between the two sides.

-

Pattern Imaging & Développement: The circuit pattern is transferred onto the copper layers using photoresist and UV light.

-

Gravure: Unwanted copper is chemically etched away, leaving behind the desired circuit traces.

-

Application du masque de soudure: The green or white solder mask is applied and cured, exposing only the component pads and vias.

-

Finition des surfaces – Immersion Or: The board undergoes the ENIG process, applying the nickel barrier and thin gold layer.

-

Sérigraphie: Component designators and logos are printed on the board.

-

Tests électriques & Inspection finale: Each board is rigorously tested for continuity and short circuits to ensure 100% functionality before shipment.

Design Considerations and Best Practices

Optimizing Your Board for Success

To fully leverage the capabilities of this PCB double face, consider these design tips:

-

Utilize Vias Effectively: Strategically place vias to create short and efficient signal return paths between layers.

-

Power Plane Strategy: While a full ground plane is ideal, you can use generous copper pours on both sides to create a stable power distribution network for your digital PCB.

-

Respect the 6mil Rule: Adhere to the minimum trace and space requirements to ensure manufacturability and yield.

-

Placement des composants: Place critical and noise-sensitive composants on one side (typically top) to simplify routing and minimize interference.

Conclusion: Your Trusted Partner for High-Quality PCBs

UGPCB’s gold-plated double-sided PCB board is more than just a component; it’s a reliable foundation for innovation. By combining the robust FR4 material, the advanced Immersion Gold surface treatment, and our commitment to precision manufacturing, we provide a product that balances performance, durabilité, et coûter. Whether you are a startup working on a Prototype de PCB or an established company scaling up Assemblage PCBA, this board is engineered to meet the rigorous demands of the modern digital world.

Ready to start your project? [Get an instant quote today!] ou [Contact our PCB experts for a design review.]

LOGO UGPCB

LOGO UGPCB